Ok so I had a stainless chip tray made for the mill table when the vice is used.

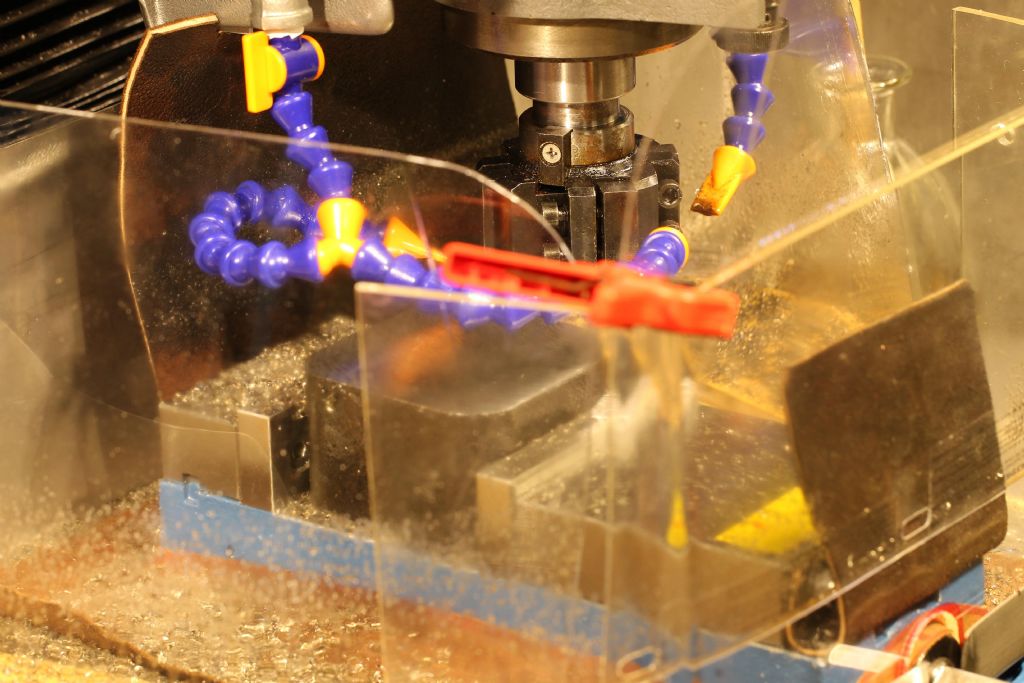

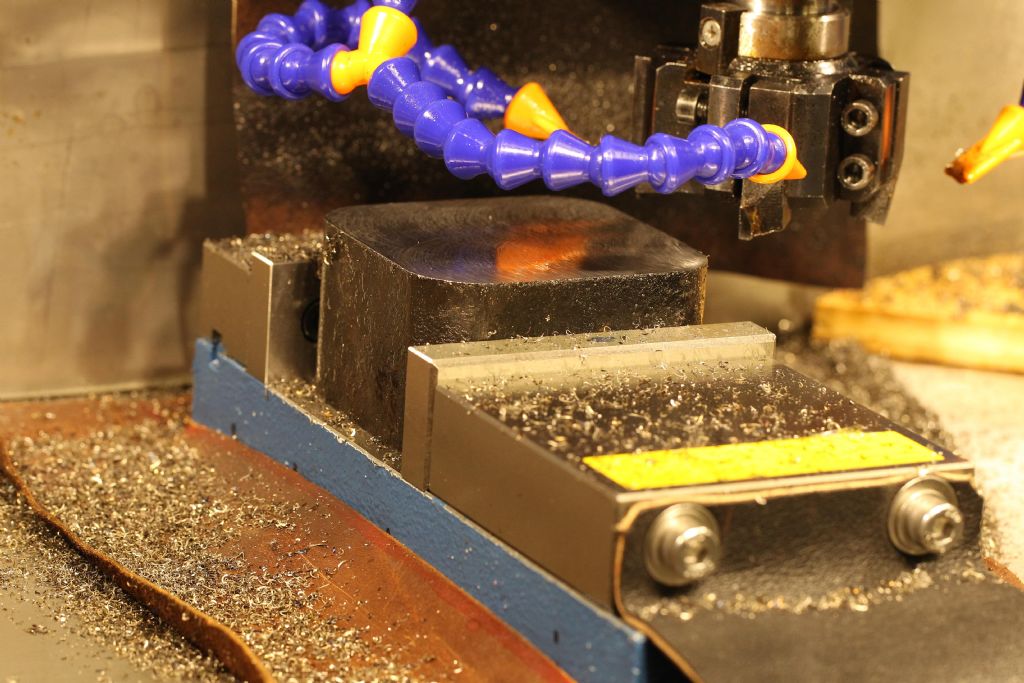

I have tested it by face milling a block of steel 5mm off one side and 2mm opposite side at 900+ RPM-Spindle. This effort contained all the chips. I used cutting fluid.

I am sure it will contain the coolant later on as well, which will leak down near vice to the bed then with a pipe bak to coolant tank.

I think I am very happy with this, and I can see well what is going on.

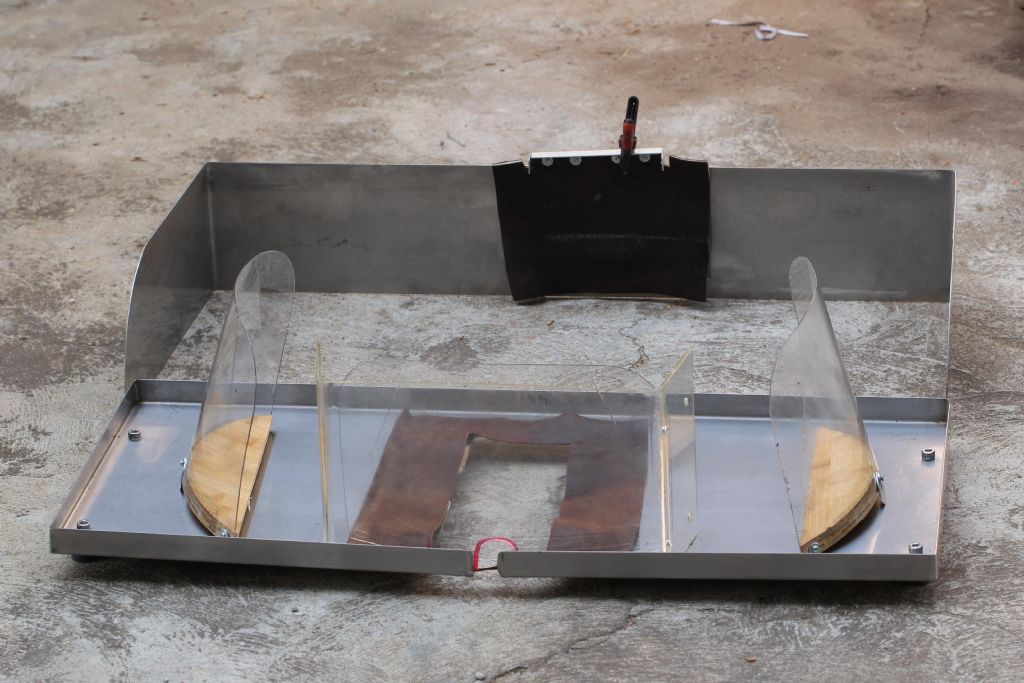

Parts Nothing bolts down, every part just slides in or sit on another, easy & fast to remove.

Nothing bolts down, every part just slides in or sit on another, easy & fast to remove.

1-Stainless Chip tray with 4x plastic feet rest on table.

-It moves with the table.

2-Stainless back plate resting on this tray. The size of the backplate can be changed for when quill & head is higher positions. This size will cover most work around the vice.

-It moves with the table.

3-2x Facermask shields used left & right of the quill to limit chips in tray area.

-These move with the table, can be easily just positioned as required.

4-The original perspex cover that came with the mill was used and slip in behind the vice on the tray.

-This moves with the table.

5-A leather piece was cut to fit around the vice to keep chips away from vice/table gaps.

-This moves with table/vice.

6-A leather piece that slip in behind the quill/spindle to catch chips near cutting tool fitted.

-This moved/stay with the quill position.

Photos added:I reduced photos size from 10mb down to 1.5 +/- to upload by loading and just resaving them in paint-jpg.

Edited By Chris Mate on 25/02/2022 14:03:59

MikeK.

Nothing bolts down, every part just slides in or sit on another, easy & fast to remove.

Nothing bolts down, every part just slides in or sit on another, easy & fast to remove.