Thank you for the reply to my questions.

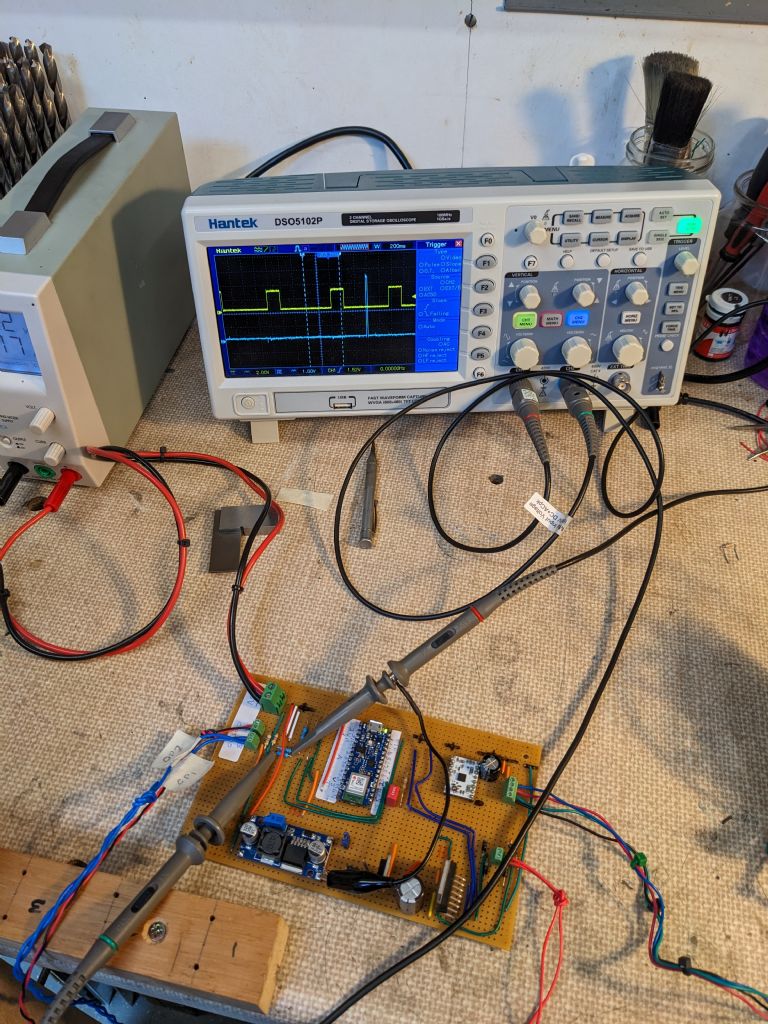

Thanks for the optical switch part number. At the moment, I'm using a cheap no-name switch with roughly 1 us rise/fall times. A part in 10^6-ish seems OK, but I'll see if that part can do better.

The slot approach reducing stray light makes sense, thanks. I've mocked up the use a pin just for low air resistance, but will reconsider.

Concerning the position of the coils, I can see your points, but it still bothers me. In a conventional pendulum clock, the impulse is most often somewhat near the top, either made by the escapement directly or through a fork a little lower around the shaft. So that's in line with your choice, at least.

In the Shortt-Synchronome, the impulse is applied roughly one-third down from the top of the shaft, but that may have been for convenience, e.g. at a position in which the swing is an appropriate width.

I guess my "bother" concerns the shaft and how stiff or flexible it is, and how the position of the impulse on a non-ideal shaft might influence performance. If I were to just naively guess where the optimum position might be, I'd guess either the bottom, the center of gravity, or the center of percussion. But I'm not sure which and haven't studied the math nor made a computer model.

The center of percussion doesn't feel right because the pendulum is not floating free in space, it's constrained at one end, and the goal is not to shift the whole pendulum horizontally. If impulsed there, an equal force on the hinge would seem to be applied. Therefore, I'd guess that below the COP would be better. The COG would probably be close to the COP, and also doesn't feel right for similar reasons. Therefore, I've naively presumed that as close to the bottom as practical would be best, if only because that would appear to apply the smallest force to the hinge (is this wrong?).

In a pendulum with a light carbon shaft and a very heavy bob (I'm jealous of your tungsten-alloy one!), both the COP and COG are likely to be very low anyway – maybe even within the bob in your case. My shaft is Invar and my bob is a brass weight that looks far lighter than yours, so that's not the case in my setup.

As Invar is only weakly magnetic (it's essentially a stainless steel), I was intending to use a steel collar a little above the weight, impulsed by an open solenoidal coil. Its position was to be just far enough above the bob for any air turbulence due to the coil to be low. I have not made the coil yet, but my thought is that the amount of energy needed to be imparted should be rather low, so the distance from the shaft to the coil may not be a difficult impediment to overcome.

It will take me a while to work through your explanation about the coils themselves.

Any further thoughts or explanations? I'll be watching this thread for sure!

Thank you again.

John Haine.

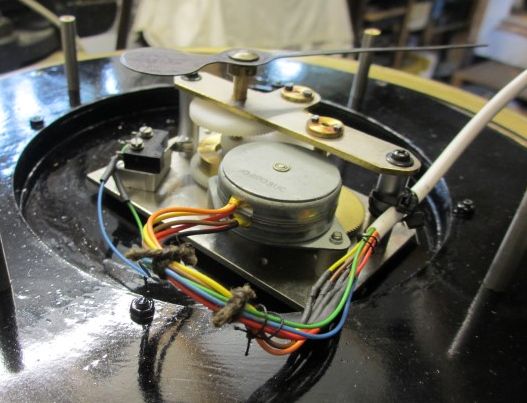

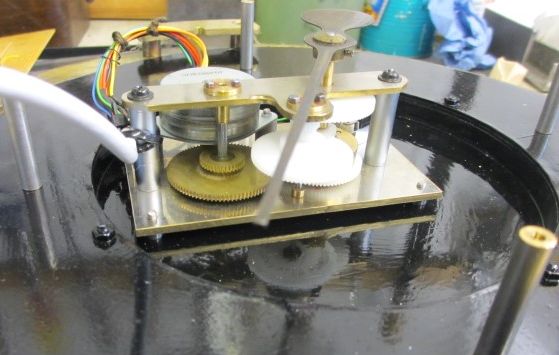

1/240), which is 5:1). The gear on the motor is the one it came with, I bought all the rest from hpc. If I wanted to drive a seconds hand in one second jumps I'd have say 48t on the motor and 60t on the seconds hand shaft. I've got a photo of the mechanism but it's on the computer in the dining room, which is like Siberia at the moment. I'll dig it out when it warms up a bit.

1/240), which is 5:1). The gear on the motor is the one it came with, I bought all the rest from hpc. If I wanted to drive a seconds hand in one second jumps I'd have say 48t on the motor and 60t on the seconds hand shaft. I've got a photo of the mechanism but it's on the computer in the dining room, which is like Siberia at the moment. I'll dig it out when it warms up a bit.

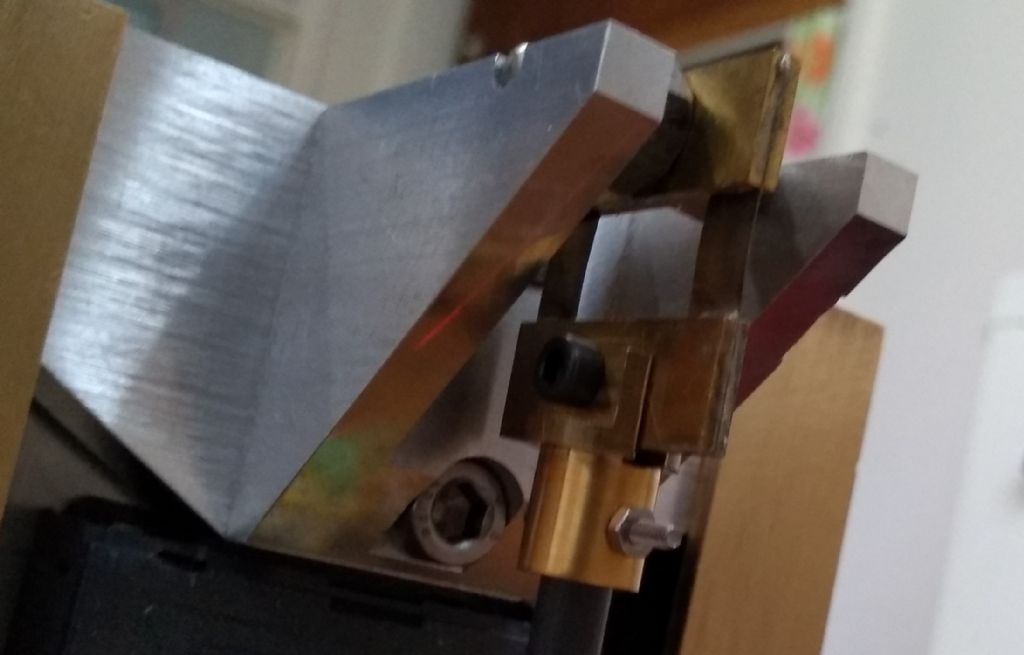

maybe 1/8 to 1/4" in width, and a spring length of maybe 1/8 inch is in the ballpark as recommended in that book.

maybe 1/8 to 1/4" in width, and a spring length of maybe 1/8 inch is in the ballpark as recommended in that book.