Hi all, a bit of an update.

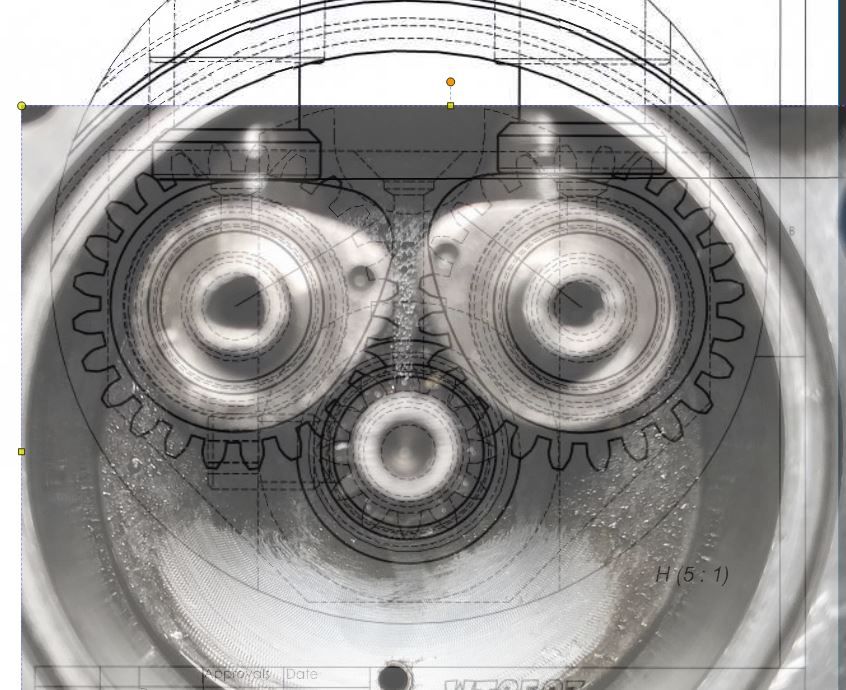

So I had decided to try making a new piston with 2 rings rather than 1 as the plans have. There was not enough room to fit 2 on the original due to the cut out used to fix to the gudgeon pin with c-clips plus the diameter of the gudgeon pin. I used Autodesk Inventor to design a new one, Obviously had to keep the distance from the centre line of the gudgeon pin to the top of piston the same to retain the same compression ratio, so reduced the gudgeon pin diameter and also did away with the c-clip fastening, instead using bronze plugs at each end of the pin to keep centre.

I had a few problems cutting perfectly perpendicular ring slots in the piston, but eventually suceeded (thanks to all suggestions from my post for help on the other page).

Happy to report after a few tanks of fuel through it today, and a bit of fiddling with carb settings I have managed to get it running fairly smooth and reliable. The range is now 2600-7600rpm, with the top end getting a bit higher with each run.

Very happy and starting to think that I will actually be able to put it in the plane that I've built especially for it.

A short video of one of the engine runs below:

David George 1.

David George 1.