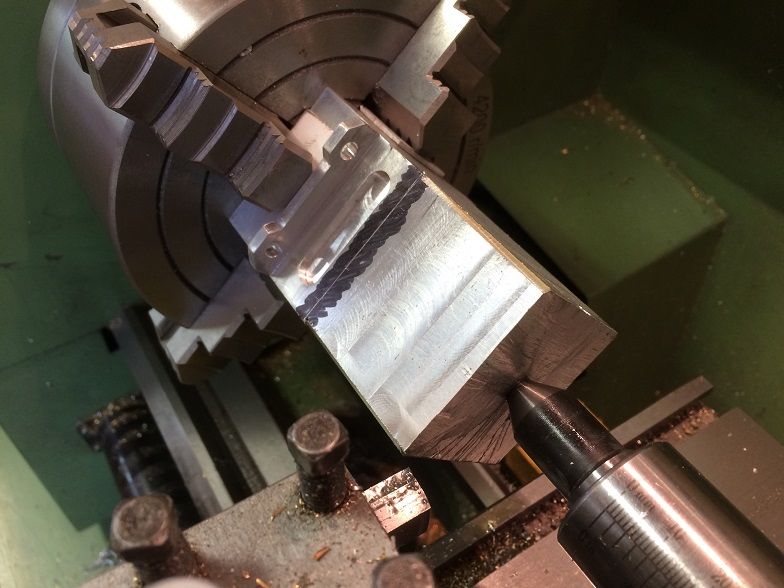

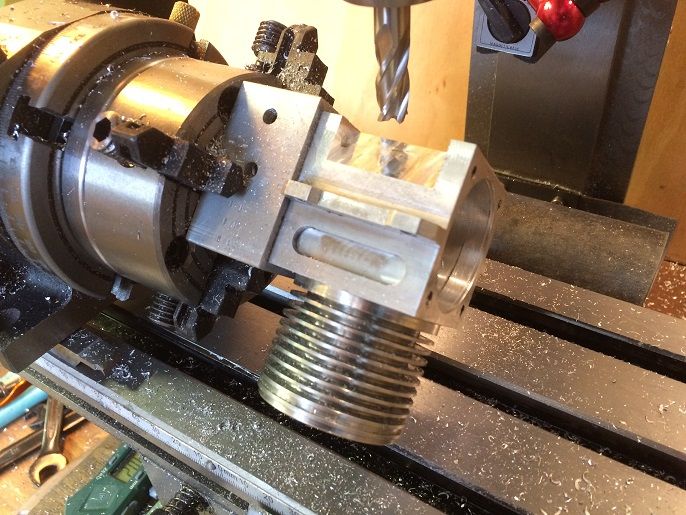

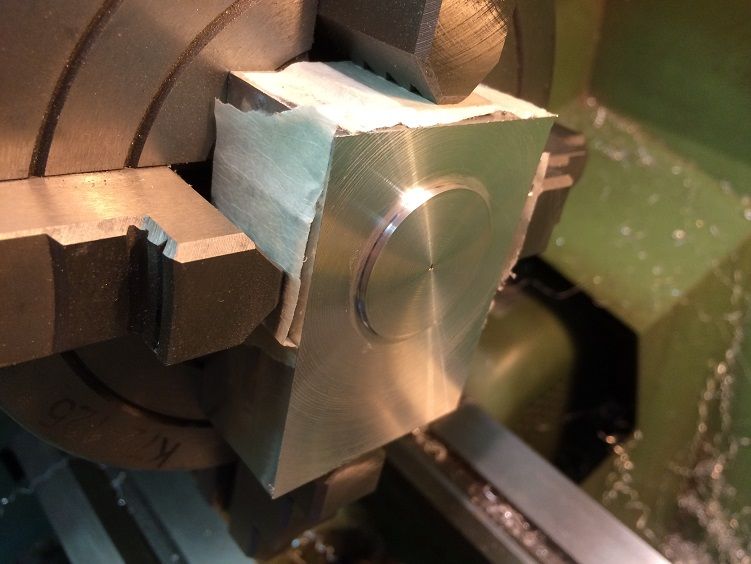

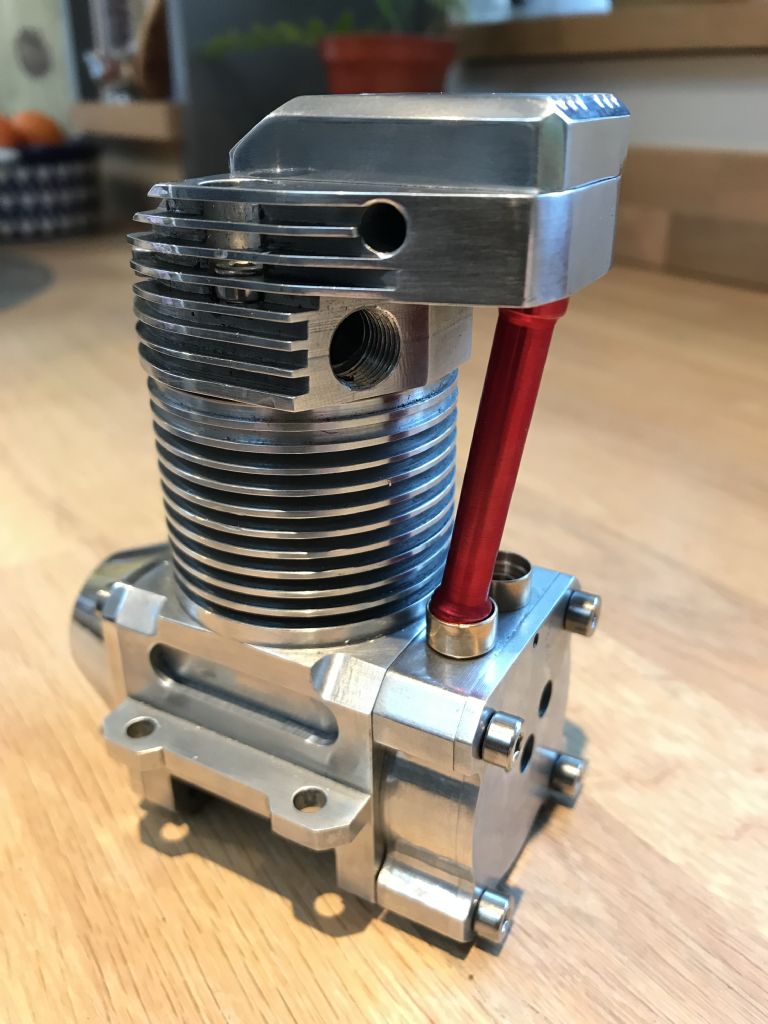

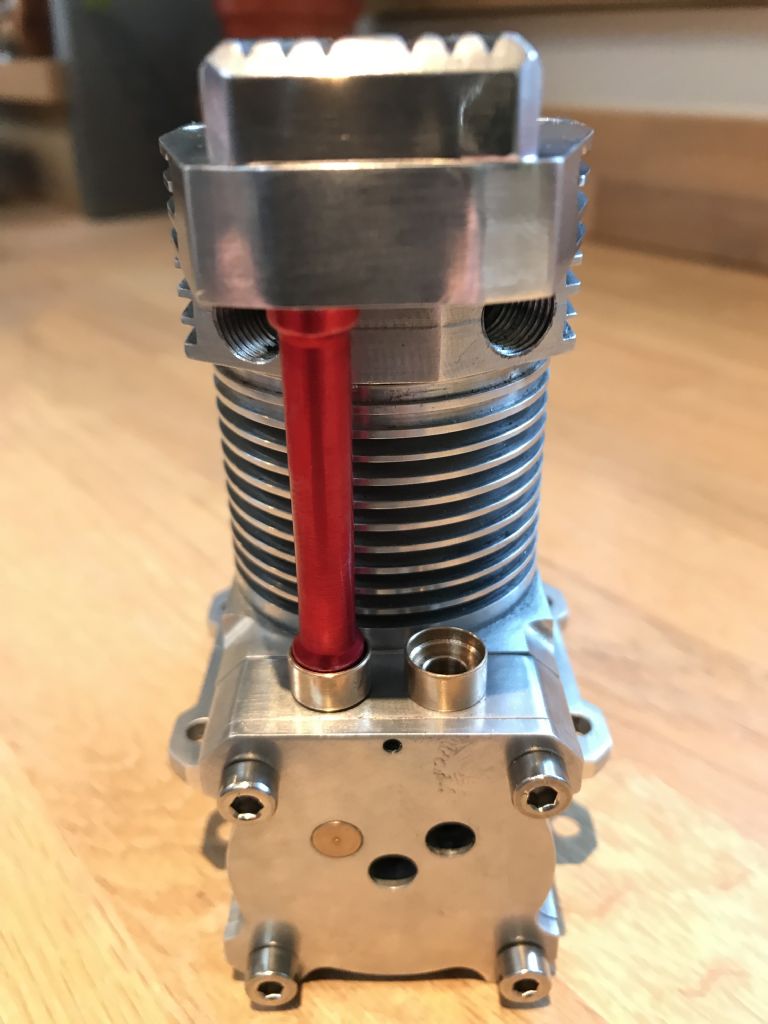

Made the cylinder liner. Had some problems with boring the cylinder and getting a nice finish which I suspect was down to my lack of experience but possibly also the EN16M material which I understand is slightly less machinable than EN8. Perhaps I could have just used EN8 for the liner?

Anyway seem to corrected the problem with a lap and now all seems ok.

I also have EN16 for the crank, but if it is going to be that hard to machine then may look to change. Any opinions? Would EN8 suffice?

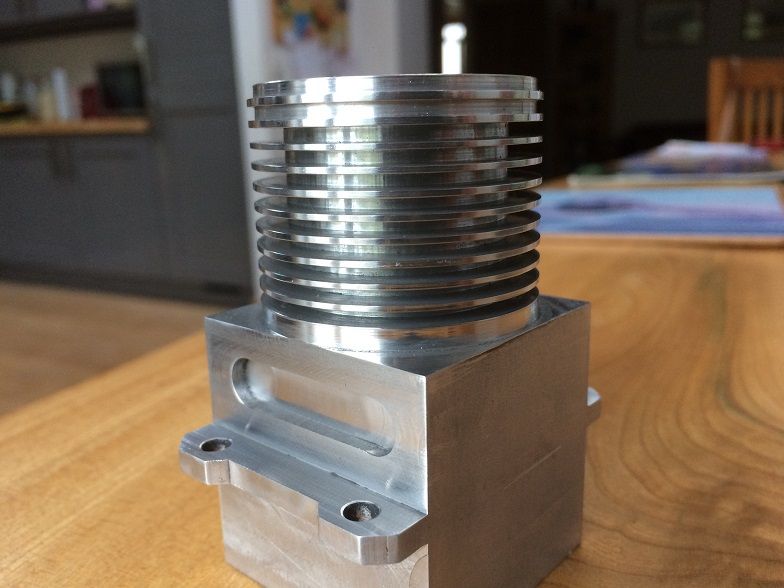

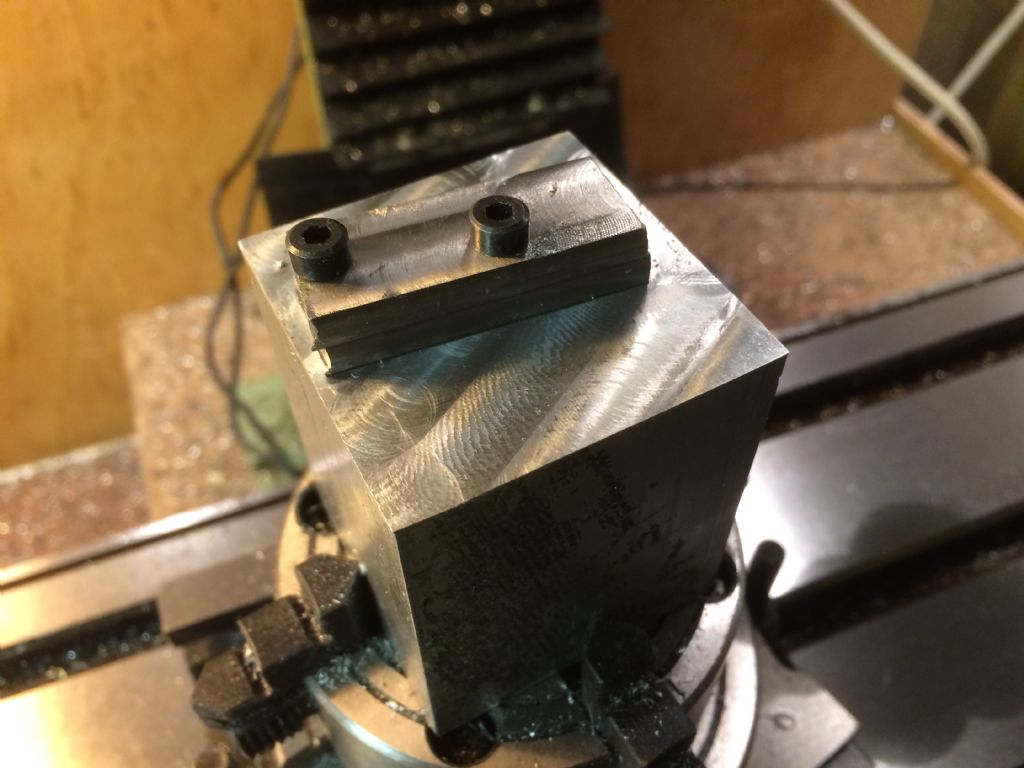

Also started making the blank for the cylinder head. That is going to be the hardest part for me to date. Plans look pretty complicated with plenty of angles and different steps. Trying to break it down into the right sequence.

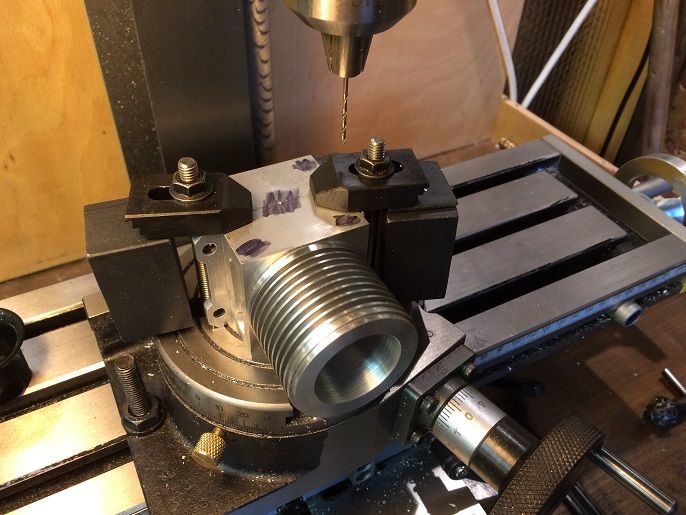

I have made the block and cut the part that sit in the top of the cylinder liner. I have then made a mirror jig of that out of aluminium 40mm bar. This should locate the jig exactly centre. Next I will drill the head bolt pattern using the mill and use those to fix securely to the jig. All other steps can then be carried out using the jig to hold it.

I am relying on a new Mill I have on order to help me. I currently have the WM14 but have been struggling for vertical space once i get the rotary table on, so have decided to upgrade to the WM16 and have also ordered a DRO set. I am hoping this will give me some better accuracy on my mill work.

(PS if anyone wants a WM14, 7 months old, little use, let me know)

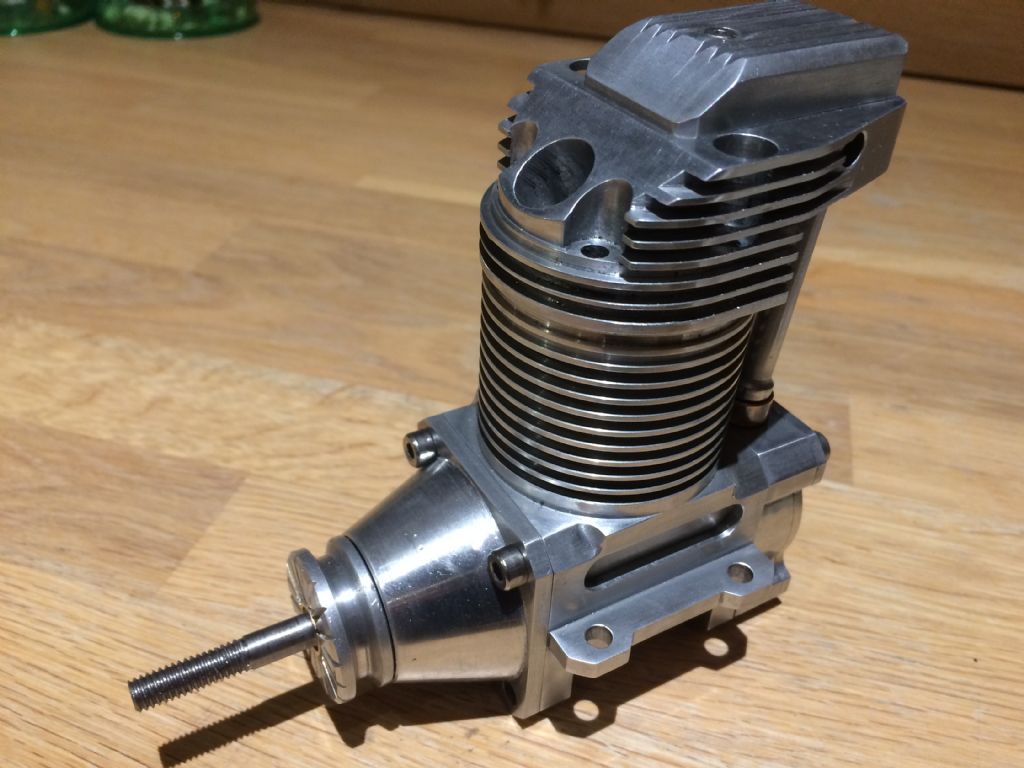

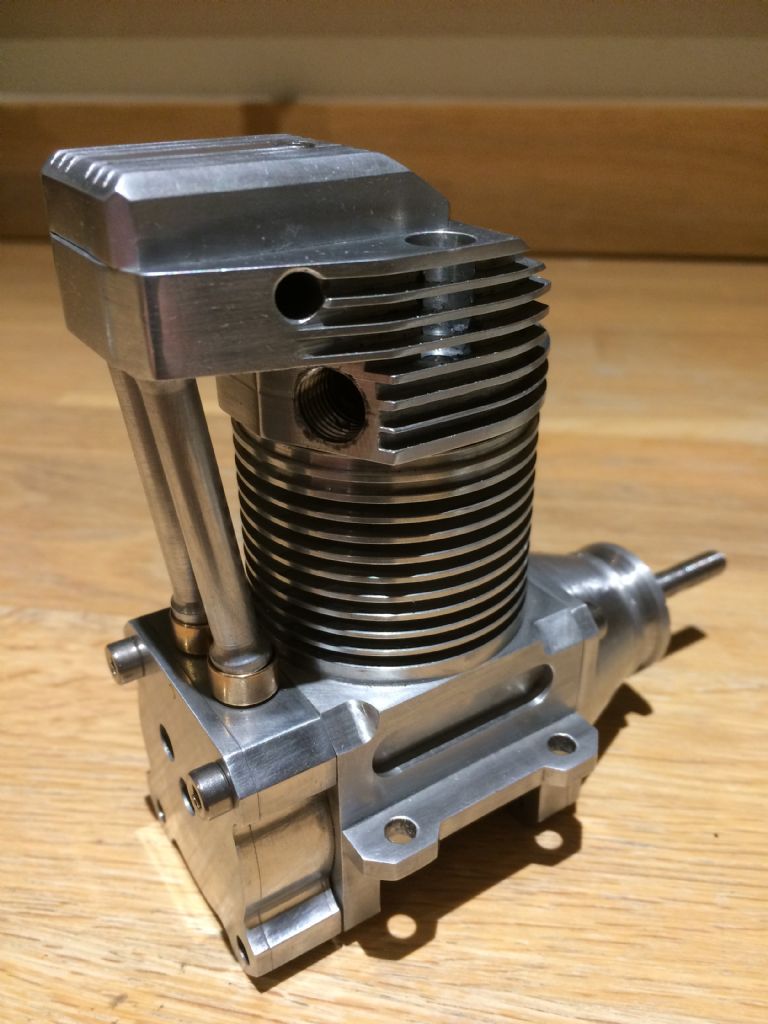

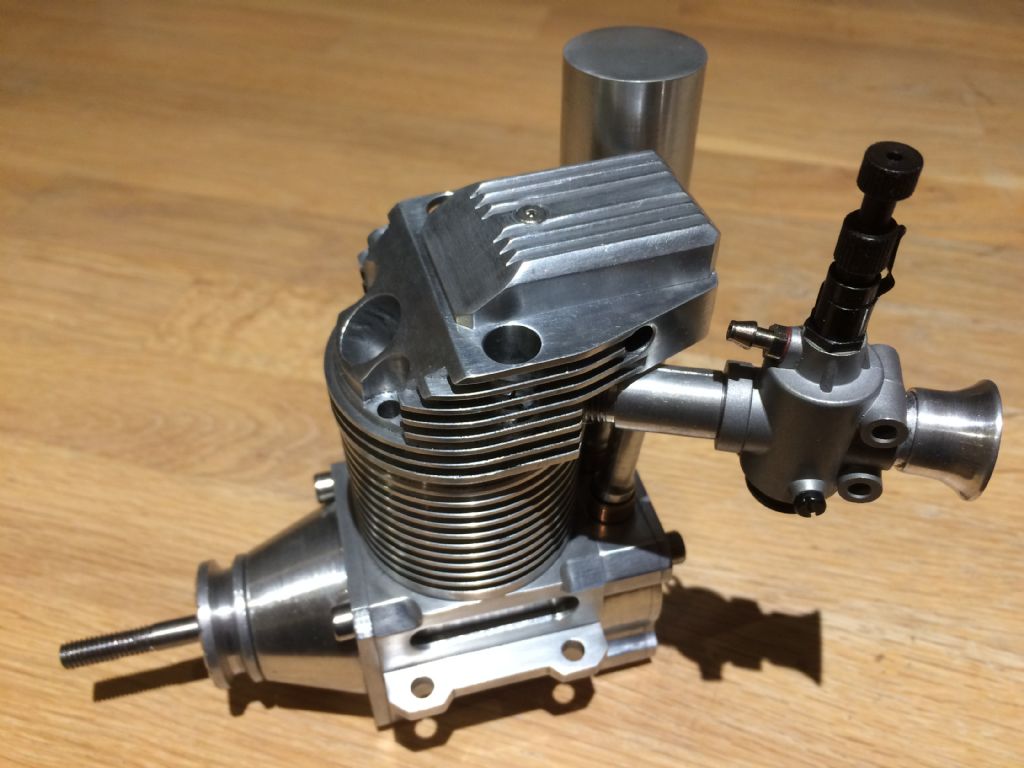

Here she is so far side by side with a Laser 100 which is currently destined for my Spitfire which is currently competing for my time.

Edited By Craig Booth 1 on 30/08/2018 12:49:53

David George 1.

David George 1.