Posted by Andrew Mawson on 23/05/2023 19:24:35:

The only meter that is relevant here is the one by which you are charged by your electricity supplier.

If IT shows excess power consumed by ballasts and capacitors left in fittings upgraded to LED then you need to be concerned as it will hit you in the pocket.

This was the case for me  any other theoretical arguments are just hot air.

any other theoretical arguments are just hot air.

Lots of posts on three different fora on this subject with no mention of what the supplier meter said! The forum posts all rely on OWL and Fluke measurements and some simple maths. I see I was not the first to mention Power Factor as a likely cause.

Domestic and Industrial power are metered differently. At the moment, UK domestic meters measure real power, so the consumer doesn't pay for apparent power. Therefore LED tubes will make the claimed power savings even if the ballast is left in place. (It will waste a small amount of real-power.)

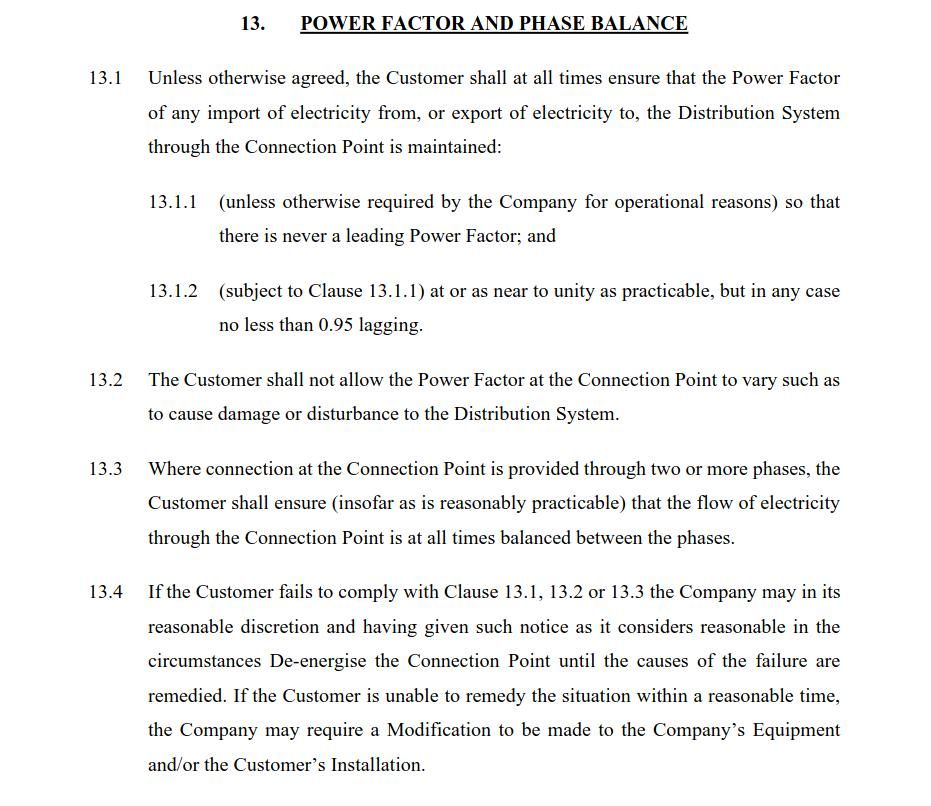

Unlike ordinary consumers, Industrial users do pay for apparent power. As their devices often put heavy inductive loads on the network, industry are encouraged to correct power factor before they connect. Could get big bills if they don't, but it depends on the nature of the load! Power factor correction involves fitting a cabinet full of capacitors, which could be static for a fixed reactive load, or dynamic if the load varies. In older installations, a man monitored power factor meters and threw switches as necessary to improve it. A modern system would probably do it automatically.

As Andrew's installation is Industrial he might well be paying for apparent power, and should be worried about the possibility. The lighting upgrade has been approached as a domestic upgrade: substitute 24W lamps for 70W units, job done. Fair enough, but there's a booby trap if the meter registers apparent power/.

Maybe saving money by not consulting an industrial electrical engineer who understands power factor was a missed opportunity? I suggest it because the whole installation could be running up bills because it's not been power factor corrected. There's a hint of this in Andrew's other posts. In addition to the LEDs, Andrew also got unexpectedly high power consumption measurements from a 30HP motor and a Beaver lathe. He also noticed measurements varied at different times; this could be because the power factor of his installation depends on what else is switched on or off.

Andrew believes he was mis-sold tubes, and the manufacturer has taken note, even though industrial purchasers aren't protected by consumer legislation. I don't think Andrew as an industrial user has a case against the retailer, and guess the manufacturer wanted to avoid messy bad publicity. I'm glad it's been resolved in Andrew's favour, even though Industry are expected to be an "intelligent customer."

Sorry to say the notion that "any other theoretical arguments are just hot air" is flawed. Ignoring engineering evidence rarely ends well! Power factor correction needs an electrician familiar with the subject, and an 'independent engineer' using a Fluke to measure amps and volts suggests he wasn't qualified in this particular subject. If the OWL or Fluke show high power on anything else, I'd send for a specialist. Power factor could be still costing more money than the fluorescents wasted!

Dave

not done it yet.

any other theoretical arguments are just hot air.

any other theoretical arguments are just hot air.