Hi, I don’t agree that those 45 degree joints should not be used, however, if the welding is of a very low standard, the welds are likely to fail, but it’s nothing to do with the joint design. To say the welds should not be taking all of the load is nonsense, but they do have to be structurally sound, …

… He should though, have someone else operating the other chain block, and they should both lift at the same time.

Regards Nick.

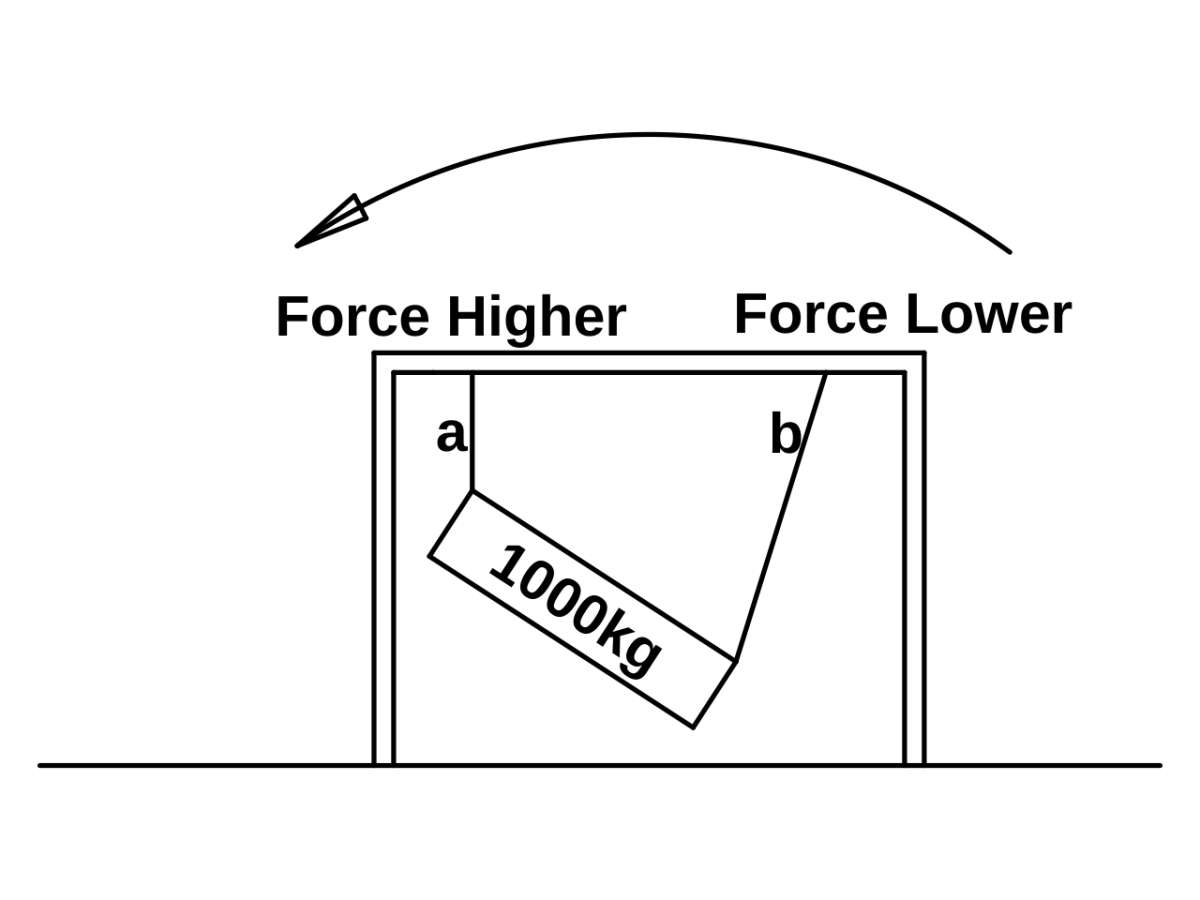

Nick has misunderstood the point. I’m saying that, if circumstances permit it, a structural configuration that doesn’t need a weld at all is a better choice than one that requires the weld to be in good order. Whilst it’s true that well-made welds can be as strong as the metal they join, we also know that welding isn’t always done well, and that it’s difficult to test without special equipment.

Nick admits that welds do have to be structurally sound. Unfortunately Sonic’s photos, skill-level and inability to test welds mean that’s doubtful in this case. That being so, replacing the crane’s top with a door lintel design, is a simple safety improvement, and I suggest there’s no good reason for not doing it. Given a straight choice between a strong configuration and a weak one, a structural engineer will go strong.

Joints in steel frame buildings are a different problem: and, Nick’s advice they are OK is misplaced, because they do collapse:

Ditto misunderstanding with the dual lift problem. A safe dual lift requires requires two coordinated operators who understand what they’re doing. The chain lift manufacturer’s instructions tell ordinary customers not to do dual lifts because it’s unlikely ordinary customers understand dynamics. Here’s an example of the professionals getting it wrong!

https://youtu.be/8_nTLIuk6Hk

Saying stuff is OK if done properly isn’t good enough, because it assumes ‘done properly’ is sorted, when there’s a chance, it isn’t. The ‘if’ cannot be ignored, and assumptions are always dangerous. Better, I think, to engage brain and establish clearly what ‘doing it properly’ requires. Identify the risks, and mitigate them. If a structure can break due a faulty weld, is there a way of not relying on the weld by using a different geometry? In Sonic’s case, the answer is yes.

Structural Engineering is ‘quite interesting’. I recommend the book ‘Why Buildings Fall Down‘ as a non-mathematical insight.

Dave

Oldiron.