Sorry to arrive late with a negative observation about Sonic’s structure, but still worth making I feel.

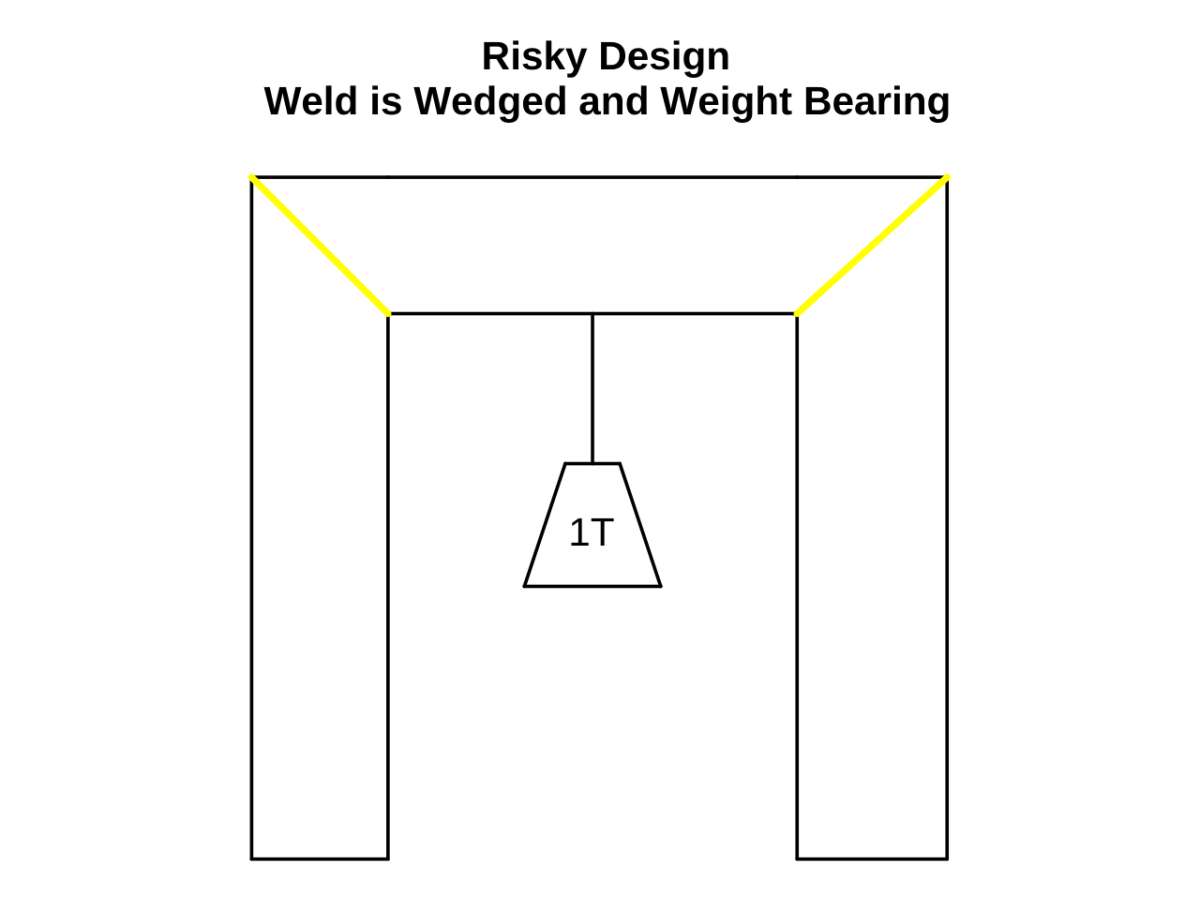

Sonic’s crane design connects box tubing with diagonal welds at the corners, which is risky:

Consider three possible arrangements.

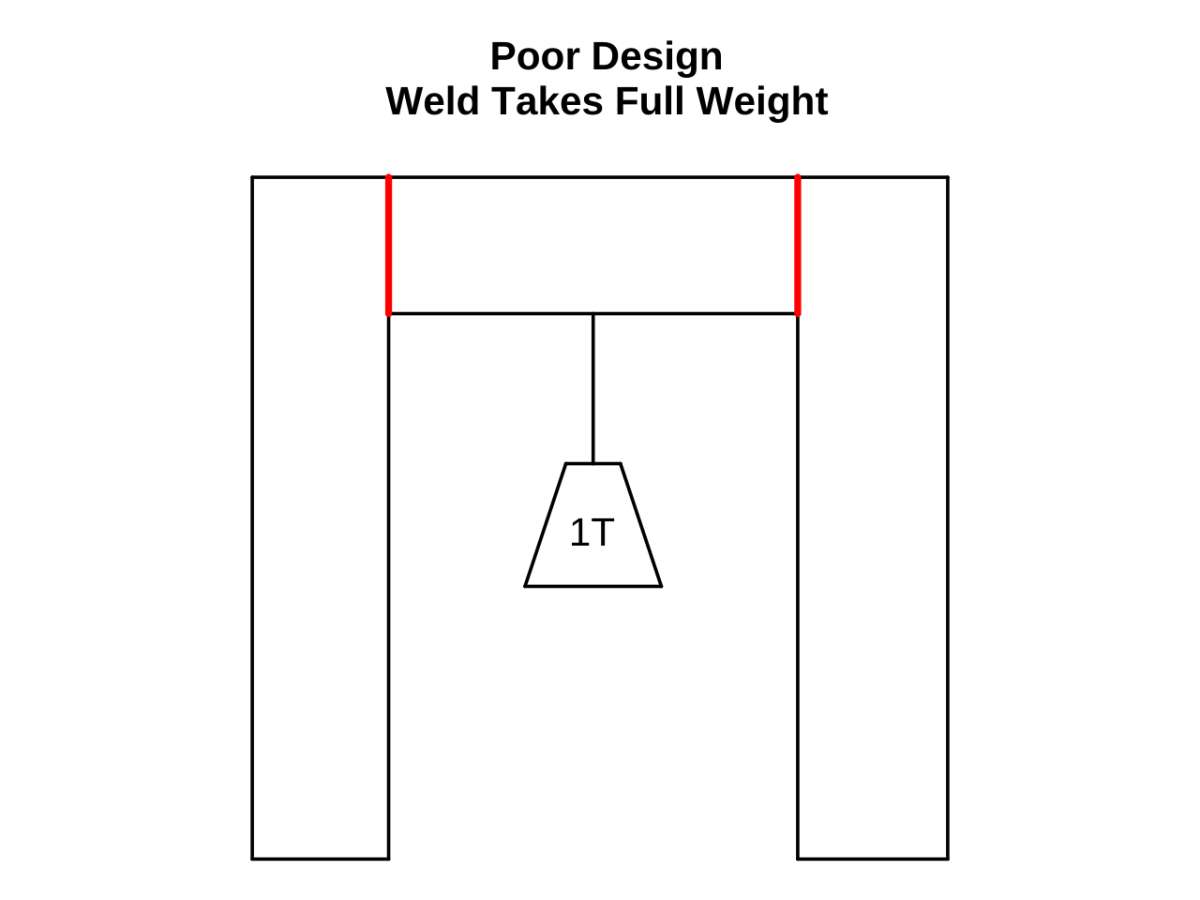

1. The top beam is welded to the columns. This is bad because the welds have to be perfect, which can’t be guaranteed in the absence of proper equipment, training, experience and x-ray crack detection. If a weld fails, the structure collapses.

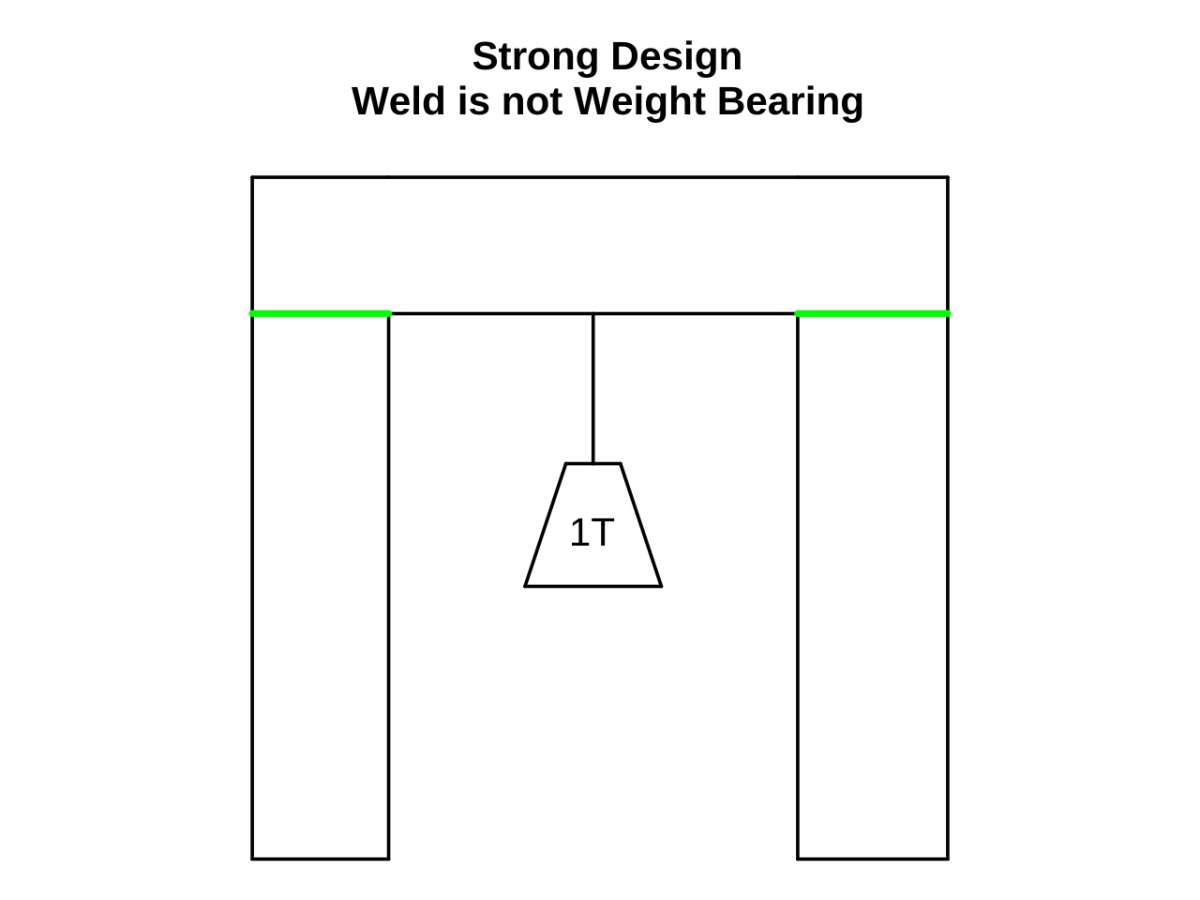

2. The need for perfect welding can be removed by altering the design so that the weld doesn’t need to be strong:

Sonic’s corner design is risky, not awful but not ideal either. The diagonal welds are stressed by the load, and the joint shape tends to wedge the columns apart sideways. If a faulty weld fails the structure will collapse.

Of course the risk of collapse in the real build is mitigated by Sonic’s diagonal side braces, but I think these are only intended to resist a parallelogrammic / scissor collapse whilst the crane is moving. However, assuring the strength of these welds is also important.

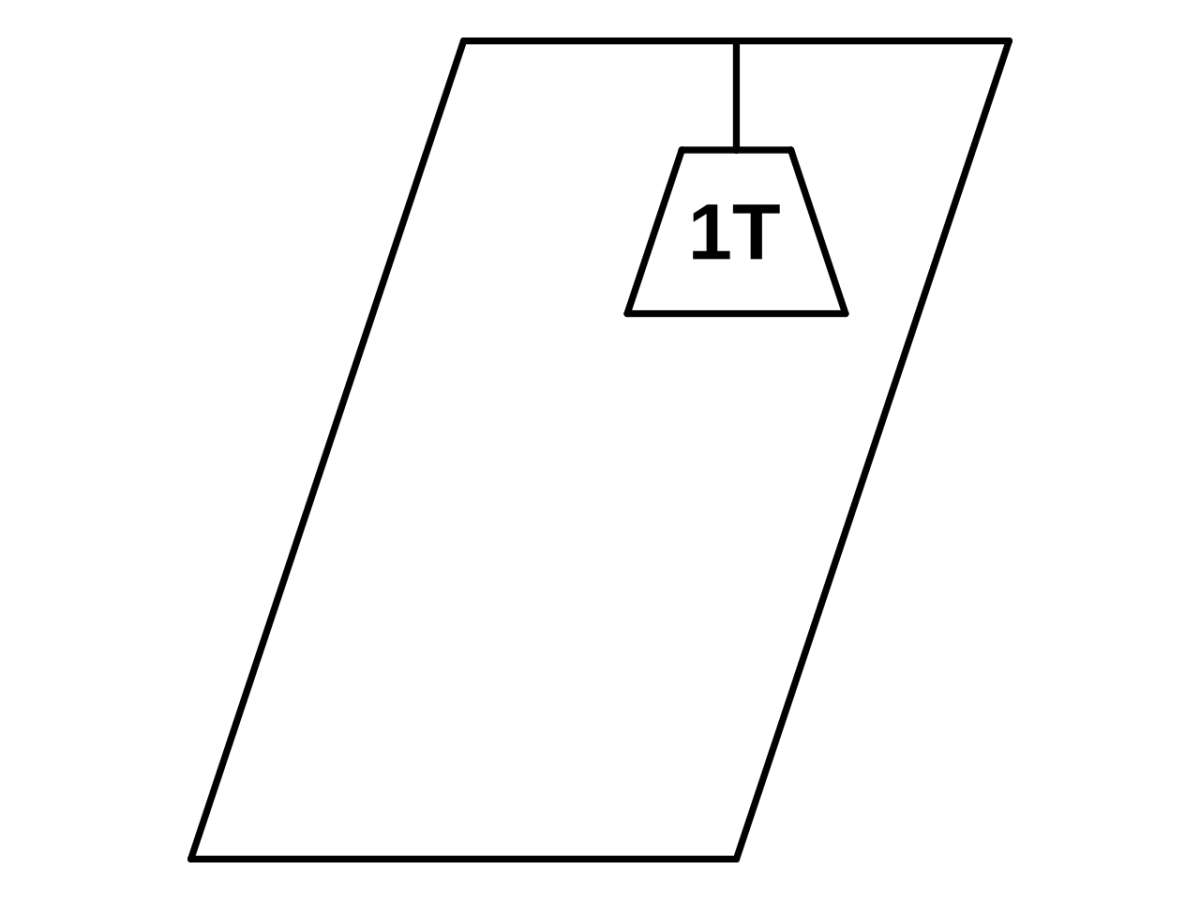

There’s another worrying issue. Sonic wants to use a crane rather than rollers because his workshop is in a domestic room with underfloor heating and a delicate tile surface. The idea may be flawed – even though rubber tyres help, wheels generally exert more pressure on the floor than rollers because their bearing area is smaller. Therefore, I suggest laying a temporary steel plate track across the floor for the wheels to run on during the move, it’s purpose being to spread the wheel pressure over many tiles.

Also, I suggest the mill be lifted up just high enough for girders to be slid under it and the crane base. Before moving the crane, the mill is set down on the girders. Then the base takes all the weight whilst the crane is moved, removing most of the strain off the structure, eliminating scissoring, and reducing the risk of the mill toppling. (Toppling is always a problem with machine tools because of their horrible high centre of gravity.)

Solid ground floors are usually plenty strong enough to take the weight of even a massive machine, but I’ve no idea how much weight an underfloor heating system will take before breaking. Anyone know anything about them?

Dave

Oldiron.