My workshop has nothing to anchor a chain hoist to for lifting, so therefore when iwas moving anything of a tall nature or somewhat unstable, there was two golden rules i did not deviate from ever The first one was do not move any machines alone, Have someone else on hand in case of emergency or an accident, Some years ago I purchased some tooling from a one man band guy in Glasgow, He took a chance moving a top heavy milling machine alone at night He lived alone Sadly the machine came over on top of him, trapping him by his leg, By the grace of God a workbench saved him from being crushed to death, He lay trapped suffering for about twenty hours

He managed by superhuman , desperation to grab hold of a pinchbar using his fingers to inch it over to himself and eventually ease the machine up enough to free his trapped leg got himself free before the whole damned thing came crashing down

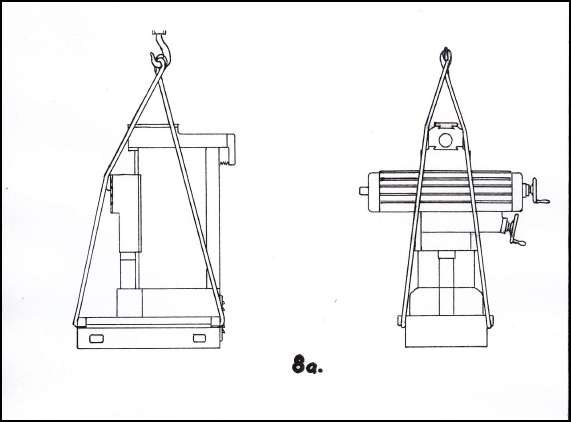

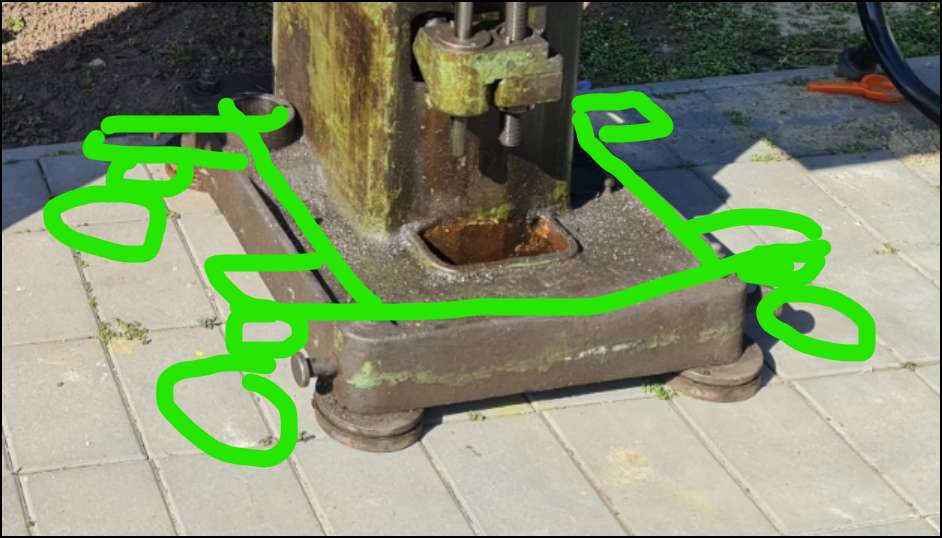

The second hint I have, the old mining & shipyard riggers trick, Ease the machine up at each corner slightly more than 1/4 of an inch, and slide under flat strips of black steel about 1/4″x 2″ , have the metal strips lubricated by liquid soap or preferrably undiuted washing up solution, Simple, After that you pinch or shove (or in my case I have a little 15cwt come-along , which I anchor to rawlbolts &anchor strips in the concrete floor, which i remove at the end of the excercise) your machine along on lengths of your flat strapping, till you get it into place Then pinch up your machine and remove your metal strips , Never would i use oil as a slippery medium , You can at finish of this chore, wash any of your soap from the workplace to avoid breaking your neck! Remember care & caution is essential.

Oldiron.