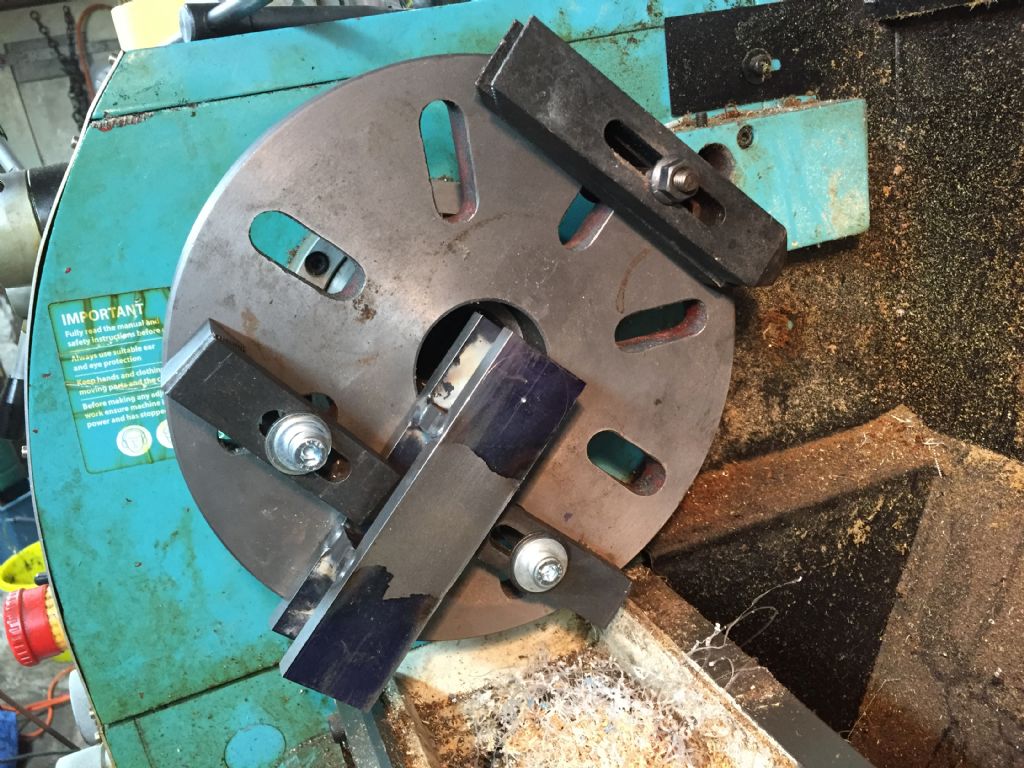

Well, safe it ain't, but serviceable – yes. I'm with you I don't like the bits sticking out beyond the periphery of the faceplate, but given that the workpiece is the size it is it don't make no never mind whether you've got one bit sticking over the edge or three. However for no better reason than to calm my nerves I'd be slightly happier if the counterweight bolt was head visible not tail visible. Anything to reduce the pokey sticky out bits.

Which brings me to the first rule of face plate work

Don't get your finger in the mangle.

Second rule is don't get anything else in the mangle either (hair, beard, sleeve, watchstrap, wedding ring etc etc…..)

Seriously though, 300 rpm – which isn't a lot if you're only drilling the pilot hole – is still enough you can't see the catch points, so you have to remember not to get close enough to get caught. It sounds obvious but make a conscious decision where the limits of the no go area are while the work is stationary and before turning if on.

Make no sudden movements – ask yourself all the time "am I still outside the danger zone if I make this next movement"? It goes without saying you must roll the work through a few revolutions to be sure nothing fouls THROUGHOUT THE LIMITS OF MOVEMENT OF THE TOOL. I find it useful to clamp a bed stop in position to stop the saddle getting too close to the headstock and potentially contacting the rotating work.

How are you going to deal with the situation where it all goes horribly wrong. Can you reach the OFF button without crossing the zone of flying debris? A footbrake is a comforting feature suddenly. Can you bring the situation back under control whilst staying right of the saddle?

Faceplate work like this gives me the heebie jeebies. If anything does shift it'll go to hell in a handcart before you can say oops. But it's very effective way of getting an accurately sized hole square to the surface.

I like Emgee's suggestion of two additional plates clamped on a diameter at right angles to the long axis of the work to be positive stops. As they are on a diameter they won't introduce an out of balance moment.

Make sure your fixings are not only tight but also clamp solid metal, you'll be fine.

Good luck Simon

PS Did I say keep your fingers out of the mangle?

Robin Graham.