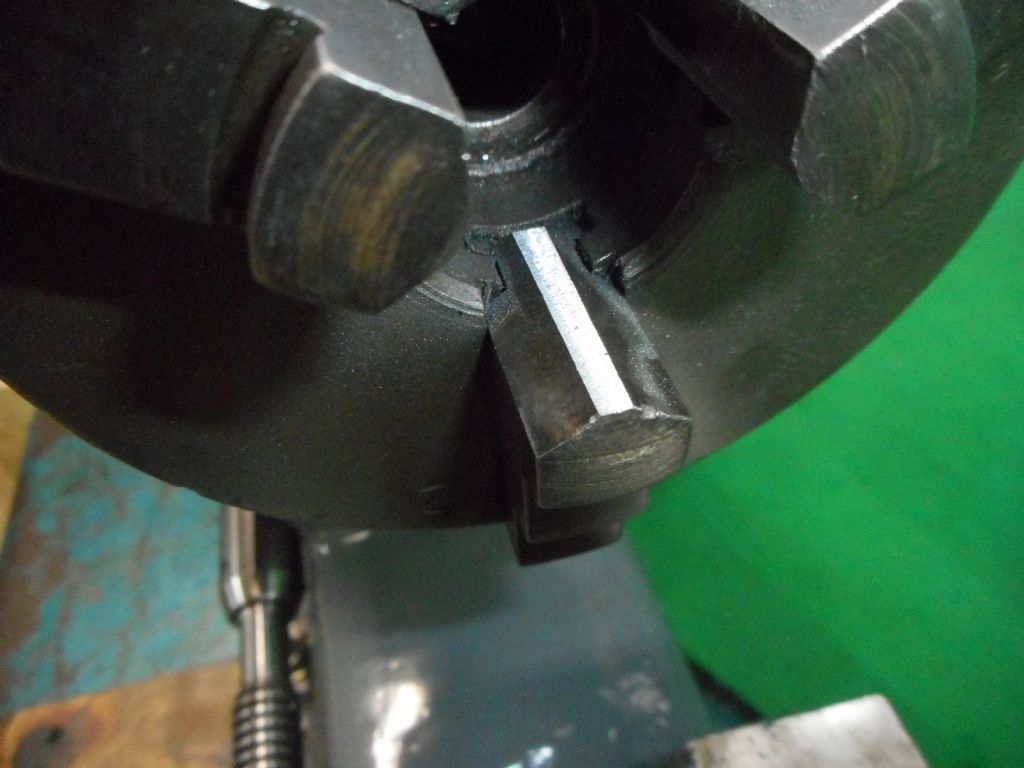

If the work is slipping in the chuck, apart from bell mouthed chuck jaws there are other possibilities.

It is assumed that there is a small lead in chamfer on the end of the work, equal to the depth of the thread to be cut.

Also that the Die is the right way round. The marked end should lead, but I have encountered an odd Die where the marking was on the back of the Die. Inserting the Die the other way round cured the problem.

Might be worth checking that the leading end of the Die is the chamfered end!

If not as the work progresses into the unchamfered section of the Died

1. The Die may be blunt

2. The Die may be overtightend

To set a Die, use a commercial 3/8 UNF bolt or setscrew, and adjust until the bolt / setscrew is slightly stiff to rotate in the Die. It must not cut

3., The Tap or Die should be copiously lubricated. Trefolex, Rocol STD or even bacon fat are good lubricants.for Taps and Dies.

4. Don't be afraid to withdraw, and clear the swarf, regularly..

If the workpiece is rather hard, you can always open up the Dies and take a first cut, tightening it for second or third cuts. The final cut should be with the Dies adjusted to a commercial thread (Which ought to be made to the correct dimensions. )

If the worst comes to the worst, having fully engaged the Die, the work can be removed from the lathe and gripped in the vice, whilst the remainder of the thread is cut using Die Holder. But apply equal force to both handles, or you could finish up with a drunken thread.

As an aside, if you are dealing with Imperial sizes, and you have the correct measuring equipment, why not work in Imperial units. 9.5 mm x 24 UNF threads are not standard, 3/8 are!.

Howard

Huub.