Posted by Terry Kirkup on 02/10/2020 15:37:22:…

…. I couldn't stop the lathe juddering or the boring bars (in tailstock 50mm boring tool holder) nodding madly! ,,,

A

That;s your problem right there. Boring heads are not designed to be used in the tailstock and tailstocks are not designed to hold a boring head. You end up with waaaaaay too much tool overhang and the essential little bit of slop between tailstock barrel and body becomes amplified by the distance/leverage and will move about all over the place. The other problem with today's cheapo Chinese boring heads is the supplied carbide boring tools are useless until they have been correctly reground on a green grit grinding wheel.

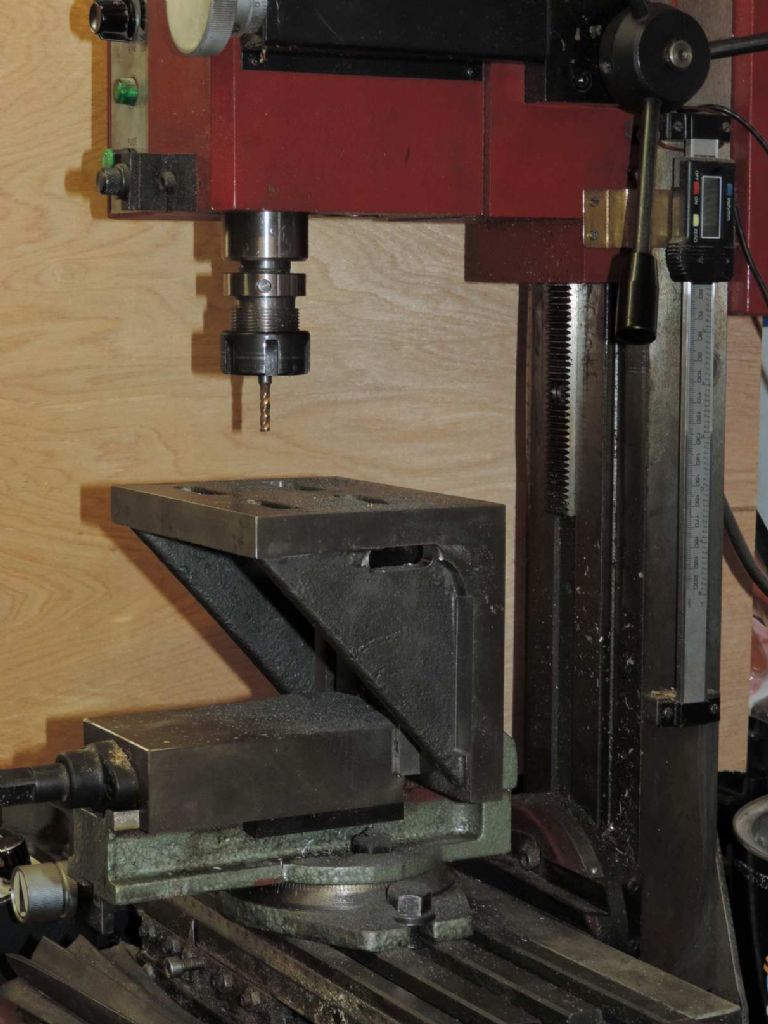

If you can hold the job securely in your four jaw chuck, the best way to bore the hole after drilling is with a stout boring bar held in the toolpost and fed along by the carriage. For a 30mm-plus hole you should be able to use a boring bar with a nice solid half-inch diameter or so shank. It should stick out of the toolpost just a tad more than the depth to be bored.

For the drilling first, start with a centre drill then a pilot drill of maybe 5/16" or 3/8" diameter then your large drill, then bore. It may help with the "juddering" if you machine a flat on the job same diameter as the finished hole so your drills have a steady flat surface to get started on. But it shouldnt really be necessary.

You need to get yourself a good book on beginner level lathe work, such as The Amateur's Lathe by LH Sparey to get the basics down pat. Forums and YouTube are helpful but no substitute.

Edited By Hopper on 06/10/2020 02:02:46

Terry Kirkup.

Terry Kirkup.

?

?