Hi all,

I've just bought an as-new WM180.

It came with all the standard bits, including a 100mm 3-jaw and "Sanou" 4-jaw.

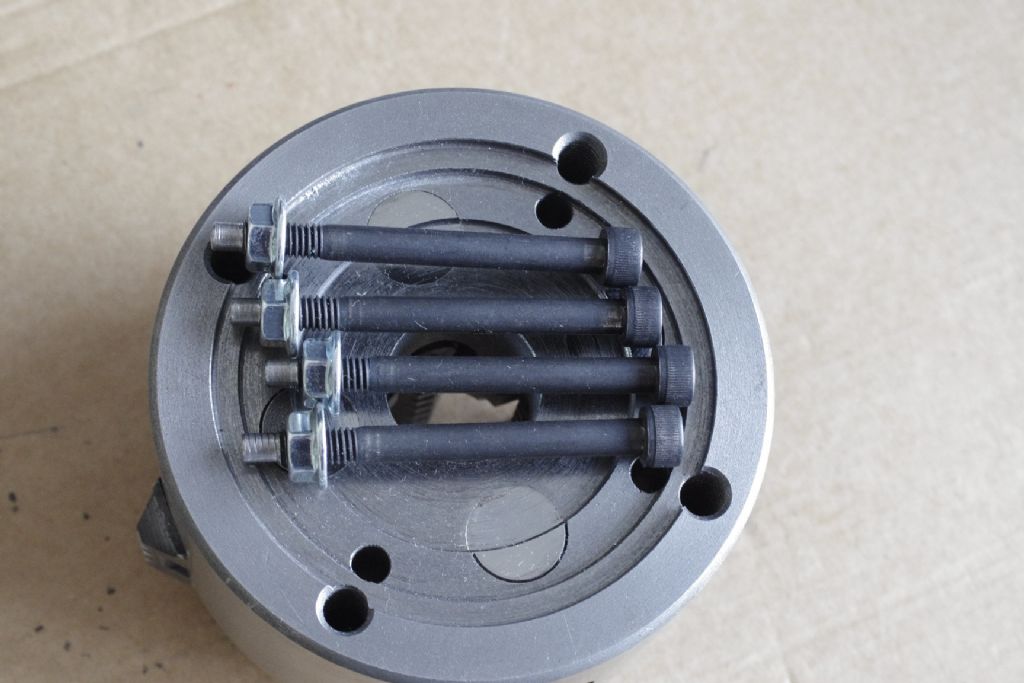

The 3-jaw bolts directly to the spindle nose but the 4-jaw has a back plate to convert from 4 M8 holes in the rear of the chuck to the standard 3 M8 studs.

I unbolted the back plate from the 4-jaw and the recess on the rear of the chuck is an exact fit over the register on the nose.

Assuming I can drill and tap 3 holes in the chuck, is there any reason why I shouldn't eliminate the back plate and bolt the 4-jaw on directly?

On the rear face of the chuck, the pegs are visible (which retain each jaw screw). I held the chuck in soft-jaws in a vice, gripped a piece of stock in it and heaved the jaws v tight. There was no discernible movement of the pegs. I had worried that, without the backplate, the chuck might try to eject the pegs rearward when tightened hard but seems not.

Is anyone running such a chuck with no backplate?

The plate is approx 18mm thick and saving that space on such a short lathe would be great.

Thanks

Gareth

old mart.

![wp_20230226_002[1].jpg wp_20230226_002[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/921833.jpg)