As I read the manual, the DNO 10 is only intended to drive a single motor. Section 13 'Expansion Connector' explains how to connect controllers in a master slave relationship: in this configuration one controller tells another, one per motor, what to do. Again as I read the manual, only two motors.

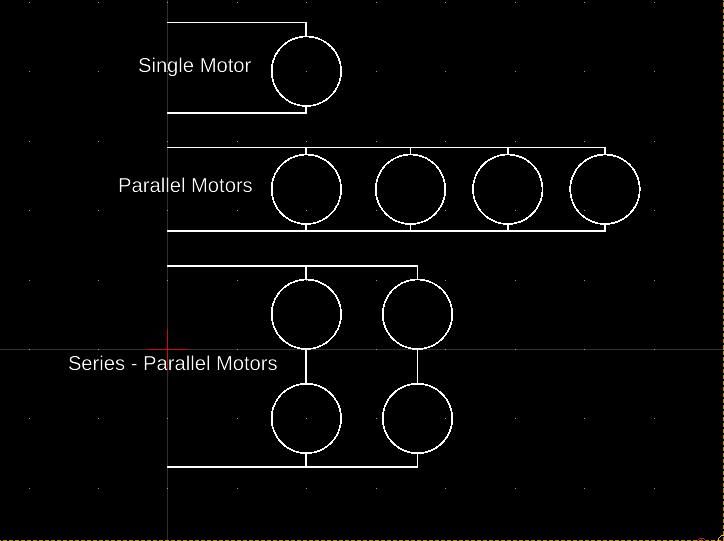

At risk, one could run 4 identical motors off one controller.

The DNO 10 spec says:

- 12V to 36V

- 100A Peak

- 75A for one minute

- 60A continuous

The most important limiting factor is 60A continuous. Whatever is connected to the controller must not normally draw more than 60A. (Starting an electric motor briefly draws more than it's rated power. to accommodate start surges the DNO 10 controller allows 100A peak provided it drops immediately to 75A for no more than one minute.

Assuming it's big enough (see capacity below) a single 12V battery would power a single big 720W motor (12V x 60A) or four smaller 180W 12V motors in parallel: 720W total, 180W per motor, 15A each.

Two 12V batteries of the same size in series, or a single 24V battery, doubles the amount of power available:

- a single big 1440W motor (24Vx60A) or:

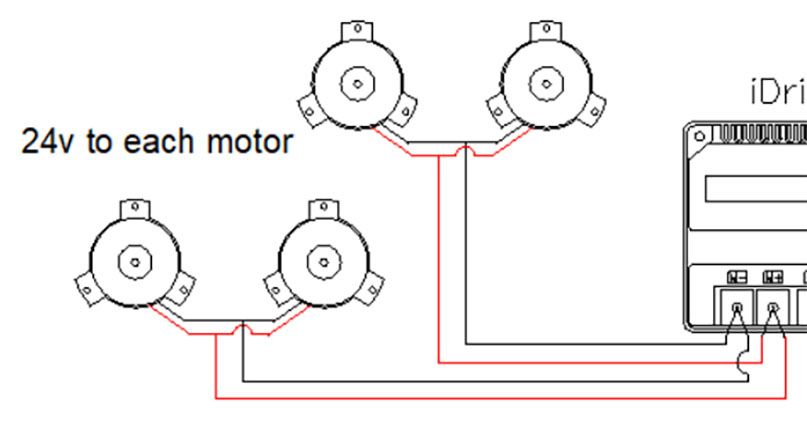

- four smaller 360W 24V motors in parallel: 1440W total, 360W per motor, 15A each. OR

- four smaller 360W 12V motors in series-parallel: 1440W total, 360W per motor, 30A each leg.

Various pros and cons. A single motor means a drive train is needed, maybe not a disadvantage if a gear-box is needed. High amperage wires get hot and waste power, so have to be made of thick copper in short runs. 60A is more trouble than 30A and 15A is ordinary. 12V batteries and motors are a bit easier to source than 24V etc.

The risk that two or motors motors could present an unbalanced load to the controller may explain why 4QD's manual doesn't cover more than one motor per controller. A vehicle should put the same power on all the drive wheels, and bad things happen electrically and mechanically if one or more wheels slip or stall. A professionally designed vehicle would allow for this, which my simple multi-motor suggestions above don't. My feeling, and I have no direct experience, is a hobby designer, driver, or club insurer need not get into a flap about balance. 'Our' electric locos are relatively slow and unlikely to get out of balance on a Club track – we're not building full-size locos required to reliably haul huge loads of iron-ore over snow-filled mountain passes!

Battery Capacity is measured in Ampere Hours. 12V Car Batteries range from as low as 30AHr to about 120AHr. In theory, a 60Ahr battery would power a DNO 10 flat out for an hour. In practice rather less, 80% or 48 minutes max. Worse, a car battery used for this purpose will have a short life – not many recharge cycles before it fails to hold charge. The problem is car batteries are heavily optimised to deliver a few hundred amps for a few seconds into a starter motor; once the engine is running, the battery takes about 15 minutes to recharge, after which it has a long rest! This type of battery is rapidly damaged by repeated deep discharge and long recharge cycles, and particularly by doing it once a week on a loco! The battery will work, but expect it to die quickly.

A Leisure Battery is a better bet because they're designed for repeated deep-discharges. But for a long life (more than about 500 cycles) even these are best not discharged below about 50%. There are also lead-acid batteries specifically made for fork-lifts etc, which perform better than caravan batteries, but are expensive. I've no experience of them but Lithium Batteries outperform lead-acid types. Although they last much longer, the purchase cost is high. I guess for hobby use an inexpensive Leisure Battery will give best value for money – reasonable life and performance without costing a fortune!

Again, I feel the designer of a hobby loco, needn't fret too much about about how many battery recharges he'll get, or exactly how many hours his loco will run for on a single charge. All that's needed is that the loco start and stop when required. It doesn't have to meet commercial cost-benefit targets over a wide range of operating conditions.

Anyone with practical experience of building one of these? I've no idea what the total weight might be. Would four small motors need a gear box or belts to improve torque, or can they drive the wheels directly?

Dave

Michael Callaghan.