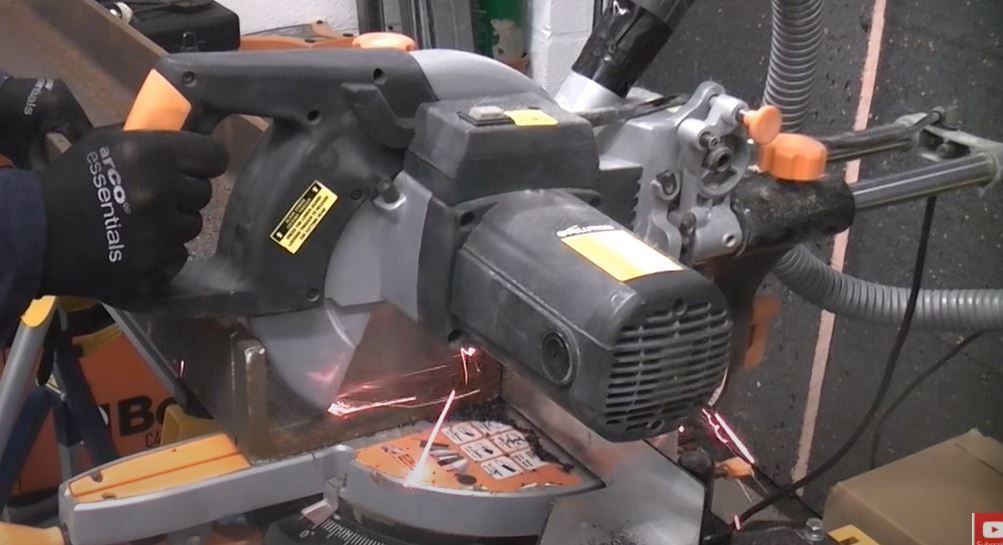

I have an Evolution 255mm carbide cut off saw, they do several so the blade size might be important.

Astonishing! The first thing I had to cut was 20×50 steel, whilst not like wood it was very close. I have cut many things with it, steel and aluminium.

What it won't like is flaky rust. Had to top and tail dozens of square section steel tube, about 40mm by 3mm thickness. Blade was blunt after a few, a new blade only lasted about 10 pieces. It seems to be like the problem of oxy acetylene cutting of rusty steel, it is impervious to the flame and won't cut at all. A film of rust as on storage surface marking is ok, but definitely not anything that looks flaky.

The other thing is the life time and cost of the blade, above comments but I have got through about 6 in 20 years, but compared with a hacksaw it is no competition.

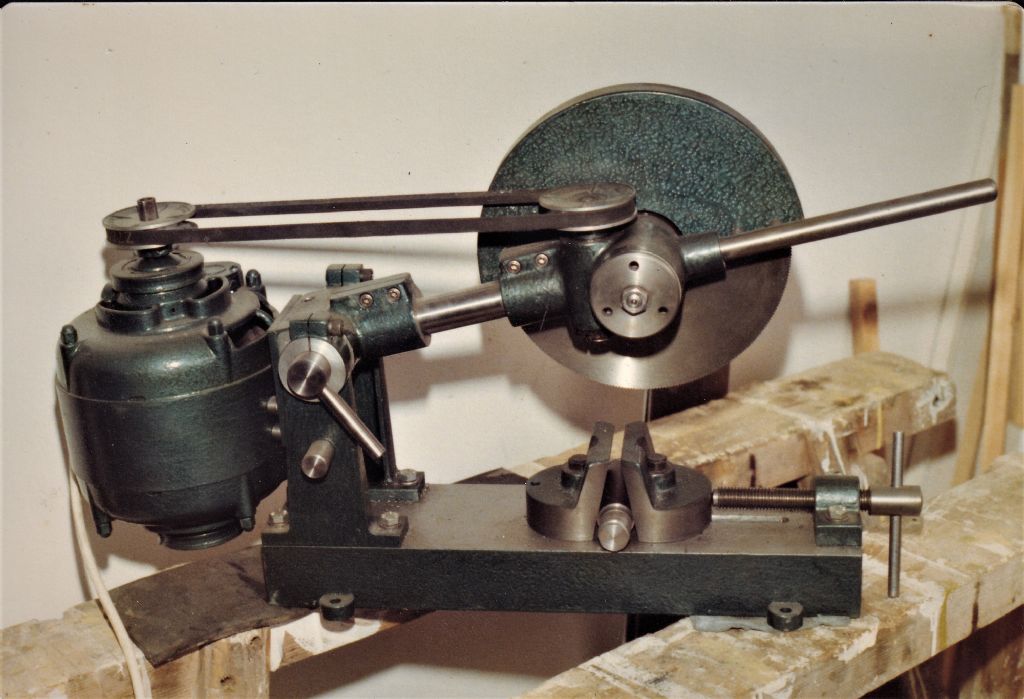

I also have a slow speed saw with the 80 tooth 10" blade. Brilliant, but gearbox failed, bought another secondhand and as AJ mentions, this one chatters, can't find out why.

The real problem I find with these saws is the vice, will they securely hold a short length of metal. Had a big hacksaw but unless the metal was 10" long it wouldn't grip, and even then it was forever slipping. Not certain angle adjustment jaws are really worth the pain.

Andy Stopford.