Posted by Peter Greene on 18/11/2020 01:17:39:

Posted by Andrew Johnston on 17/11/2020 21:31:49:

The real problem was that 84 of the 90 bolts were 8-32 UNC rather than the correct 10-32 UNF, so were too small a diameter.

Did this come out of some kind of official investigation or is it simply internet "information"?

I commonly use UN hardware on this side of the pond and based on my experience, I was having real trouble imagining this so I just popped into the shop and checked. I'm still having real trouble imagining it.

An 8-32 screw in a 10-32 hole is as loose as the proverbial pigs' droppings. Wobbles around so much it feels likely to drop right through. Presumably the "fitter" who assembled the screws was at least slightly qualified for the job, in which case he couldn't fail to notice something was wrong IMO.

And since it's an aircraft assembly, was there no QC person in attendance?

Further to andrews informed comments, there were other aspects to this.

1/ The "fitter" was actually a manager, who while technically qualified (a licenced engineer), no longer reguarly worked "hands-on" He was doing the work because of staff shortage due to industrial action.

2/ The screws went into thin-wall anchor nuts that are deformed to provide self locking. This ment the 8-23 was tight.

3/ The engineer used the prescribed click type torque wrench but did not have a magnetic holder for the 1/4" hex drive screwdriver bit. He used a standard 1/4" socket and held in in lace by hand. Access is awkward and it is thought he mistook the click of the 8-23 skipping threads in the deforned nut for the click of the torque wrench. He could not see the screw turning because his hand holding the bit was in the way.

4/ Windscreen fasteners are not critical items so no dupliicate inspection is required.

5/ it is thought the 8-32 screws were in the wrong bin.

Not part of the report but personally I think the pilot was probably leaning forward, possibly investigating noise from leaking air, when the windscreen panel blew out. If he had been sat back with harness fastned it is unlikely that he would have been sucked out. It is also rumoured that the crew who saved him by holding his legs thought he was fatally injured and were more concerned about his body hitting the tail of the BAC 1-11 and causing loss of control.

As usual with accidents this did not have a single cause but a chain of events.

A more recent fastener error which fortunatly only resulted in extensive damage to the aircraft (Ryanair 737-800) shows he systen is not infallible. This critical nut with dual locking was left off completly when Boing built the aircraft resulting in parto f the under-carriage coming through the wing.

http://www.aaiu.ie/sites/default/files/report-attachments/Report%202020-014.pdf

Robert G8RPI.

Edited By Robert Atkinson 2 on 18/11/2020 13:13:11

Samsaranda.

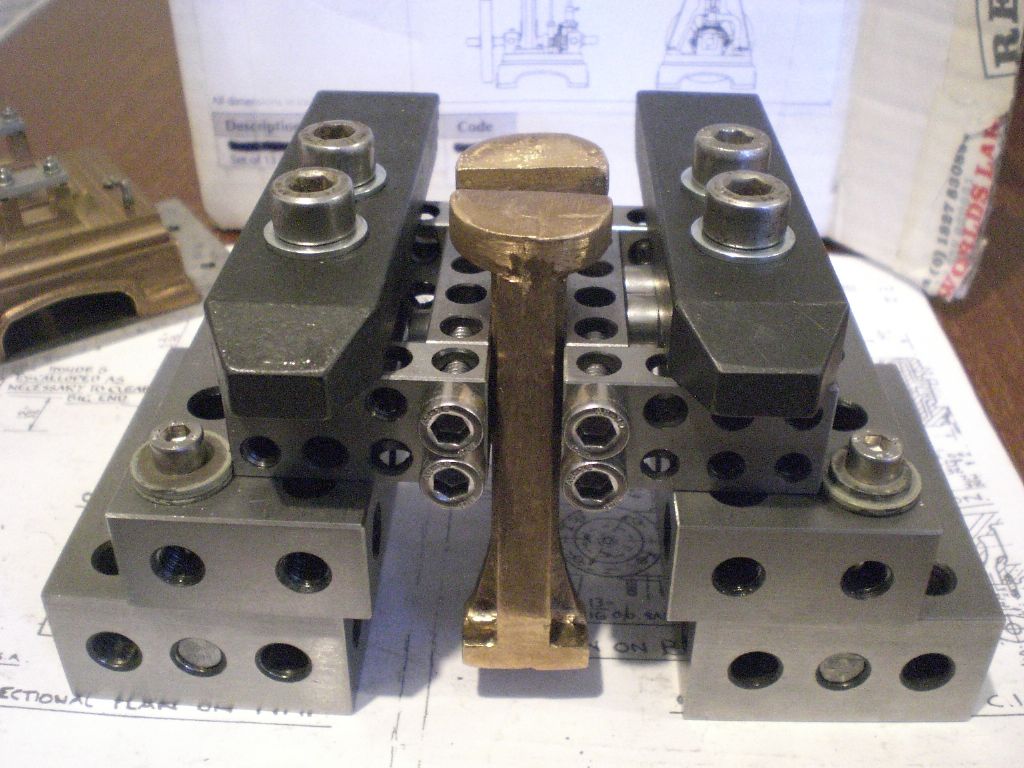

![20201118_105625[1].jpg 20201118_105625[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/881313.jpg)