What a good question! I can't remember ever using the threaded holes in my blocks, which I bought expecting them to be metric. I just checked – they're; M8, which doesn't help MC at all.

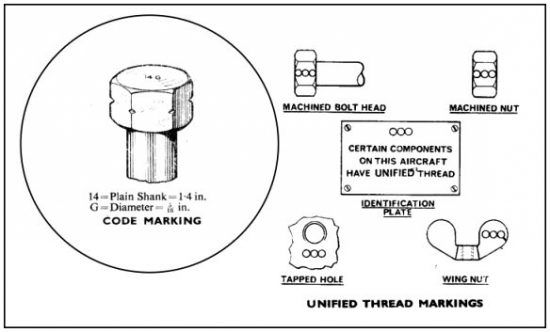

My guess is MC's blocks are most likely 3/8"x16UNC because it's a current thread-form common in the US. BSW is unlikely because it's been fading away since the UK standardised on Unified Threads in 1948,. BSW survived in UK motor manufacturing until about 1980, but since then hasn't been used in new designs. Unified threads didn't replace BSW wholesale in the UK because metrication provided a better alternative.

BSW and UNC ⅜ x 16tpi threads fit together, but it's not recommended. The fit is weak because the thread angles are 5° different – low holding strength, and liable to come apart when vibrated. More likely to be done by accident than deliberately but the bodge may not matter in 1-2-3 blocks. If it does matter, the Internet is your friend. Although new BSW are hard to source, there are loads of people selling them second-hand on ebay. UNC are available new, but they too are gradually fading away.

Advice to anyone setting up a new workshop in 2020, go metric young man!

Dave

Samsaranda.

so all camera and grip equipment have male and female threads that work with legacy UNC and Whitworth kit.

so all camera and grip equipment have male and female threads that work with legacy UNC and Whitworth kit.