I also use Alibre. When I bought my copy I went for the top of the range, as I needed the sheet metal facility, but as Jason says there are cheaper versions available. The software does have some irritating features and limitations, but that is true of all CAD software. I've just finished a project where an outside company designed an injection moulded case using Solidworks. They spent most of the meetings thumping the computer and cursing the software. One big limitation of Alibre is that it is not good at free form surfaces, but that is unlikely to be a problem for steam engines.

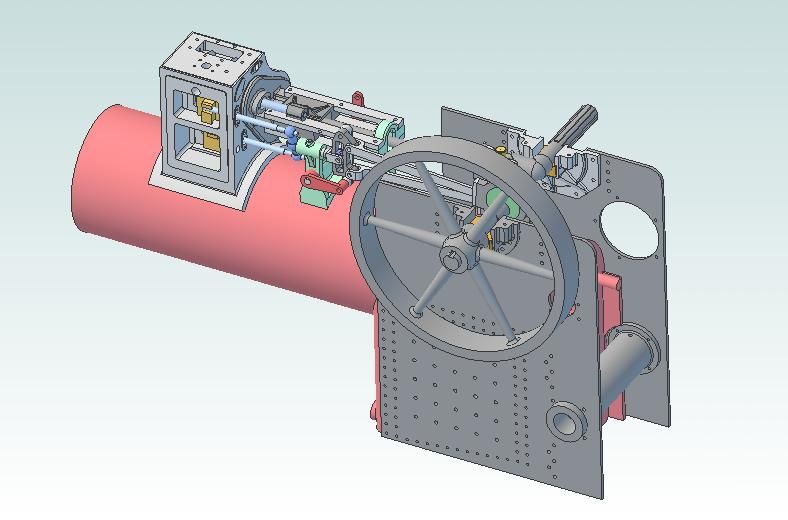

Here's an assembly of parts for the motion work on my traction engine. So far it has proved that the paper drawings are a complete fantasy, almost none of the parts fitted together as drawn. And the valve gear appears to be wrong too.

On the assembly I can rotate the crankshaft and see how all the parts move in sympathy. PM me an email address if you want a PDF of the above which you can pan, zoom and rotate.

Dimensions are inherent to the creation of the 3D model. Alibre is also parametric, which means that the dimesions can be equations. I am designing the traction engine in imperial so I can enter 7/32 in the dimension box instead of working out the decimal equivalent. I have had to make changes in the design as some material is only available in metric sizes. So if I need to take 6mm off a dimension I could type, for instance, 7/8-6/25.4 in the dimension box. Finally for a square I could dimension one side with a number and it would be allocated a name, say D1. Then for the second side I enter D1 as the dimension instead of a number. Then, if I change the size of the first side, the second side changes automatically.

Using a 3D CAD system requires a very different mindset to a 2D CAD system. If you can think in 3D and see how parts are built up from simple 3D shapes it helps enormously.

Regards,

Andrew

blowlamp.