felis

Angle plates to use on a faceplate are a classic "wait until you have a job for one then buy the size that suits" item.

In this game its awfully easy to spend too much money on things that you expect to need but in fact never do.

I've got lots like that.

Mostly purchased in my early days, usually because they could be got "right now" at a bargain price. Fortunately I always operated under strict pocket money rules so, objectively, not stupidly wasteful. Helped by the things that did get used coming in at much below the normal commercial price compensating for cupboard queens.

Back in those days (1970's) things were much more expensive new and harder to get so bargain hunting just in case made sense. These days adequate quality at affordable prices is common so the "buy it now before its gone" strategy isn't the best.

When there are 35 or more years between purchase and first use its possible that the purchasing departmental strategy was less than ideal! Some kit has been waiting longer. Like my Keats angle plate, 40 years and counting! Wonderful device but never had the need. £2.50 I'll never see again!

If you are still certain you will need an angle plate you ideally need two. One about full face-plate diameter for larger things and one about half diameter. Smaller plate will be lighter and easier to balance. Fastening work is an issue.

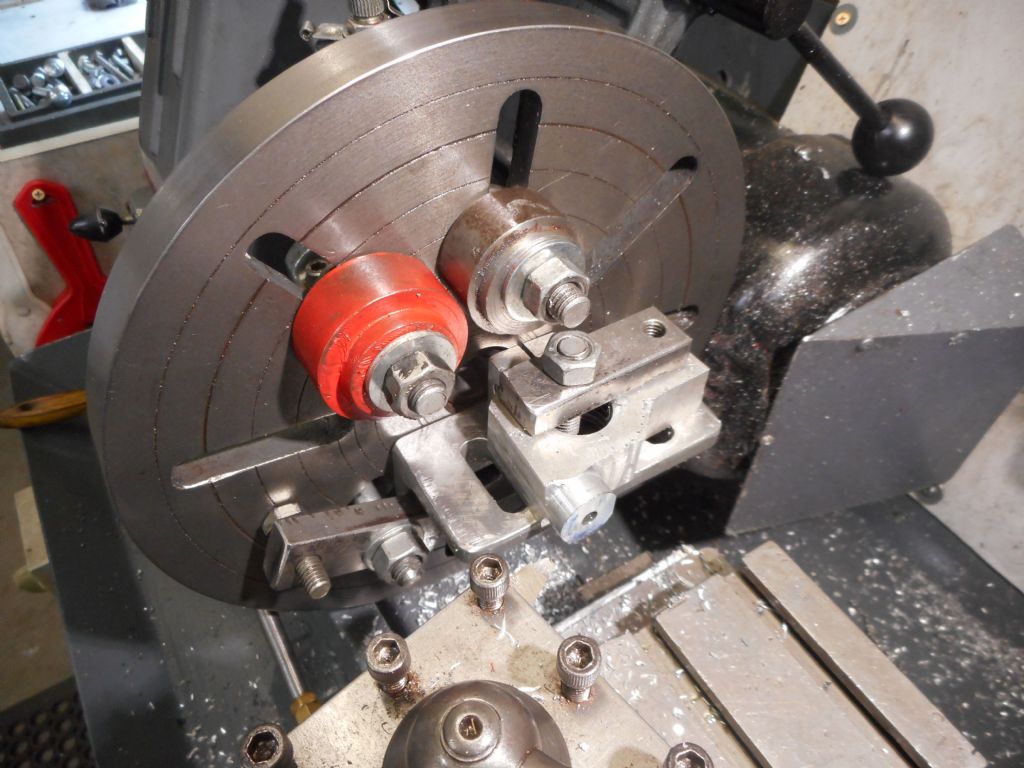

I don't have one, apart from the afore-mentioned Keats. I make up a suitable carrier using whatever is to hand, either heavy angle, weld up scrap or just a lump of alloy bar. Drill and tap holes for mounting bolts and trim down to minimum size for lightness. Bin, either scrap or useful waste for next time, when job done.

Its a pity that the modern faceplate only has radial slots. The old type having radial ones in one half and parallel ones in the other are far more versatile when mounting things.

I've never used a lathe dog either!

Clive

Hopper.