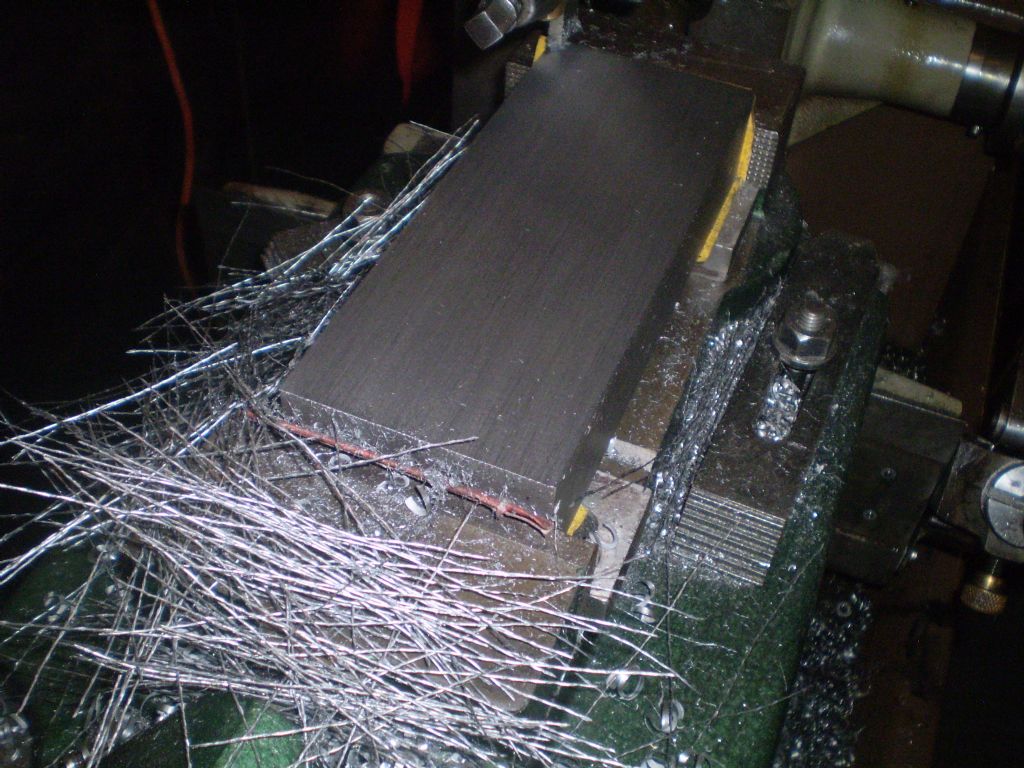

Just recently put my Drummond manual shaper to good use, making the T-section horn-plates for the travelling beam for a workshop overhead hoist. The beam is essentially a 6-foot gauge bogie!

Horns for limited, rubber-bush suspension because I envisaged setting the steel-angle rails true and parallel in two planes in a concrete shed 16 feet long by nearly 6 wide, would be asking a bit much.

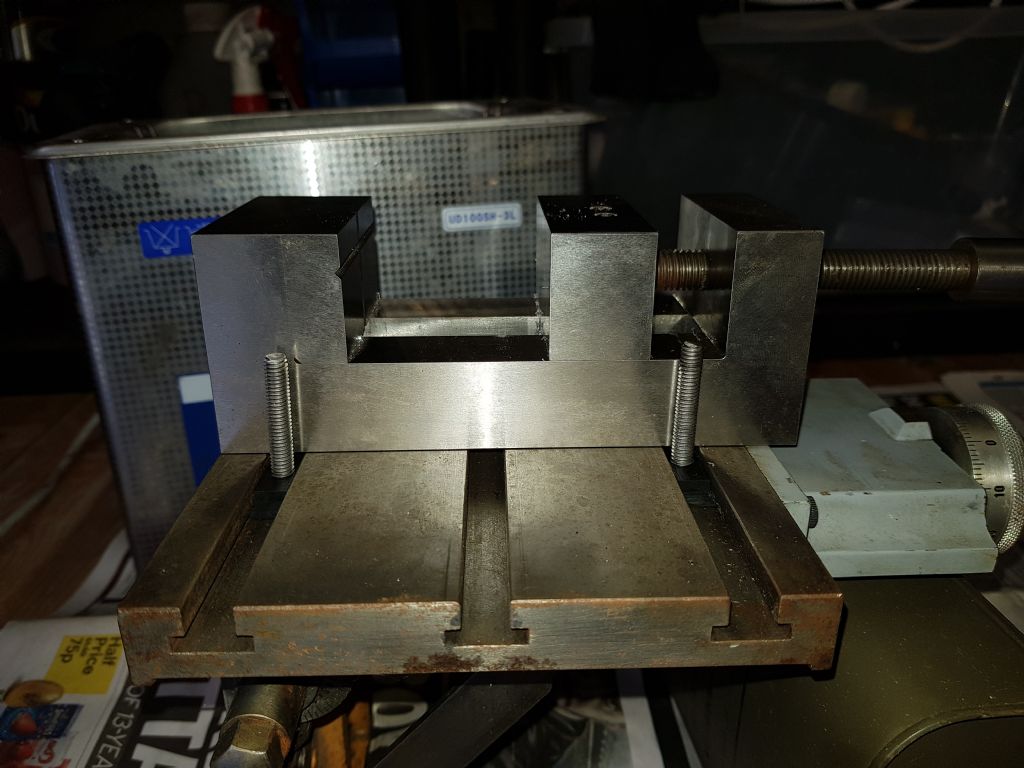

Yes it would have been quicker on the mill but this proved so problematical and frustrating that I did it the slow but much surer way. The shaper has no dials or stops, so I improvised:

– Step width by clamping a plate to the bed and working the feed by hand the last little bit;

– Down-feed by securing a simple sheet-brass pointer to the top slide cover by one of the cover's own screws, to indicate meeting a weeny pop-mark on the flank of the vertical slide, with the knee screw left at one setting.

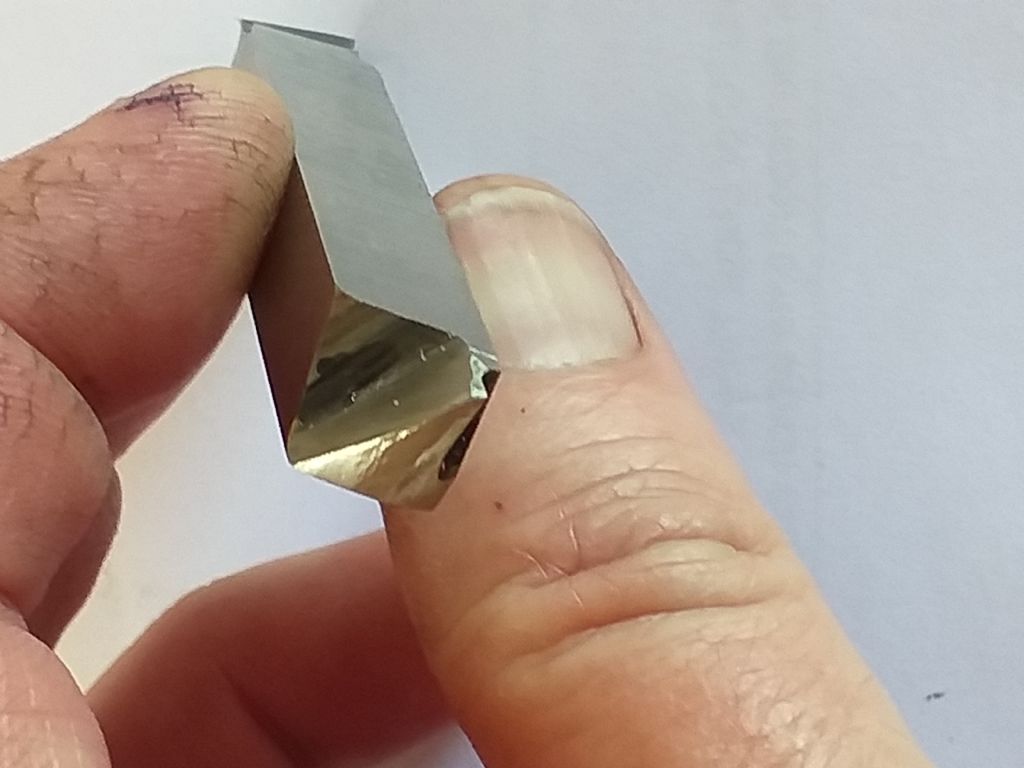

Ground an old lathe tool back to bring the edge closer to the clapper-box fulcrum (many shaper users seem to miss that the edge should be vertically below the pin), and set the cross-feed gab to just one or two clicks on the ratchet – whatever that equals in thous or one-hundred-and-twenty-eighths. *

Bevelled the approach face of the work so the tool didn't slam into a vertical wall each time, judged down-feed increments by eye along the hand-wheel spokes, and used 'Trefolex' to help the cutting.

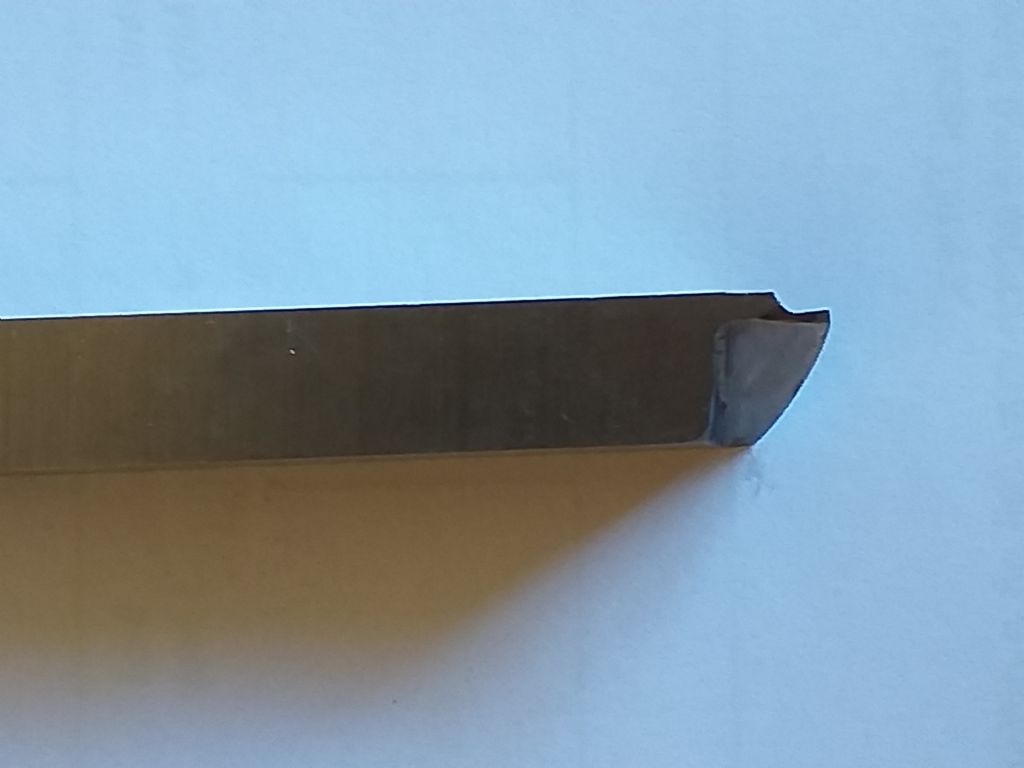

I don't claim my work was as accurate as the shaper ought allow, but I obtained reasonable repeatability to rule, scribing-block and test fit, for parts that will be bolted to a hot-rolled angle-iron frame, not a 5-inch g. 'Britannia' . However, the finish was very pleasing, much neater than the 'Artex' finish from milling.

In fact for some model- rather than tool- engineering purposes, a shaped / planed finish might be truer to prototype than milling would give, where an "as-machined" surface would be correct. (Interesting point: is that lovely satin sheen on preserved machinery, factory-finish or from years of being wiped over with oily rags?)

It kept me quiet for a few physically active but relaxing locked-down hours, and I could hear the radio above the gentle sounds of the machine (unlike the racket the milling-machine makes).

'

* Awkward fractions… I have, or had, a rule with a 1/128 divided inch on it! At least that's a binary fraction, 1/8 of 1/16 (= 0.0078 inch).

In my workshop-equipping queue is a Denbigh H0 horizontal mill, a small but useful machine. There was a superbly restored and equipped example but badged "Patrick" rather than "Denbigh", at the Sandown exhibition a few years ago. The only fly in the cutting-oil is that two of the screws on mine, including I think the long feed, are of 6TPI! The third, I forget which, is the more conventional 8TPI, but 6? 0.16666r lead? Why?

vintage engineer.