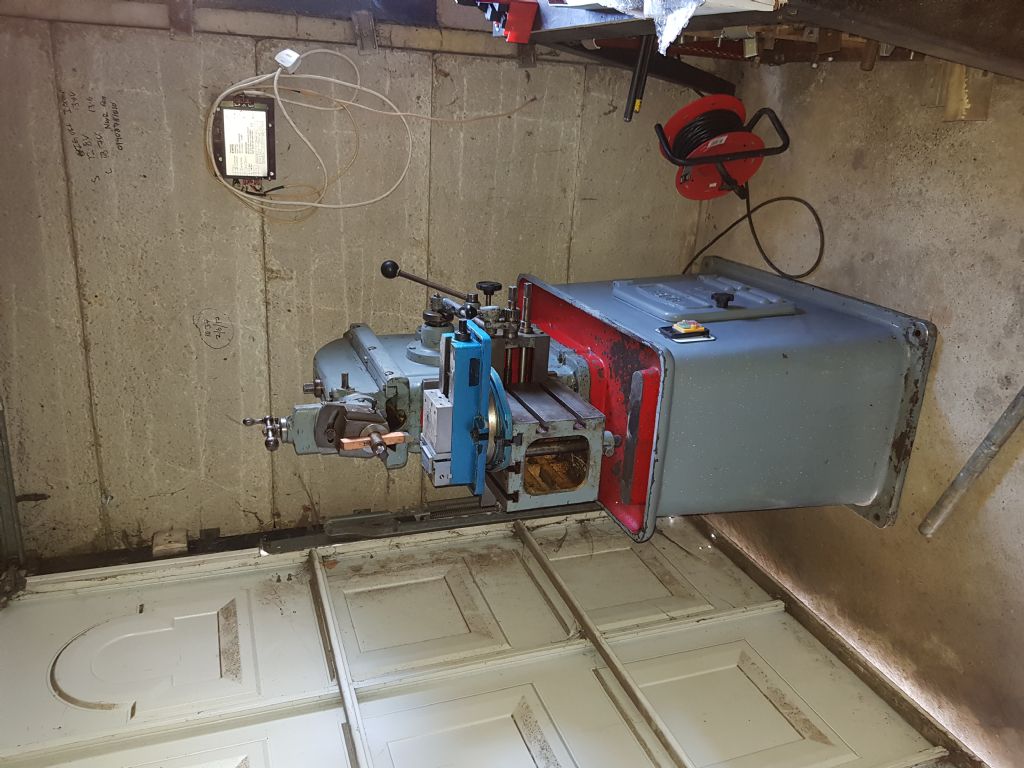

For the shaping between centres, yes, for a circular part you use the worm drive on the dividing head for a feed. But you can also make flats at arbitrary angles by setting to the angle, then taking a cut with the normal table feed. My eccentric straps used a combination of those techniques. The bottom half of the strap is a circular arc between the two "ears" for the screws, and the top part is a trapezoidal shape. I made a long piece of the section desired, then sliced it up into the four pieces needed and cleaned up the sides in the lathe. Then they were halved to make the top and bottom pieces.

Note that the supplementary table can do either concave or convex, depending on the slope of the angled guide bar.

Someone further back mentioned keeping the cutting edge back relative to the clapper box. Ideally you would do this, but it is not always possible. One case is when cutting keyways in a bore, and another was cutting the inside of my expansion links, which needed a tool that stuck out in front. If you can, have the cutting edge behind the clapper box, but if you can't, make sure things are as rigid as possible. My 10 inch Alba came with a set of Jones and Shipman tool holders, the kind that take a quarter inch square bit. They are the sort meant for a lathe, and this means that the tool bit is out in front, but despite this they work very well on the shaper. That is not to say that the proper shaper ones would not work better, but since they are pretty rare these days, try what you have, Just making sure things are as rigid as possible.

I have ME back to about 1944 with a few before that, so if you can't find the 1950 article give me a shout and I can scan it.

vintage engineer.