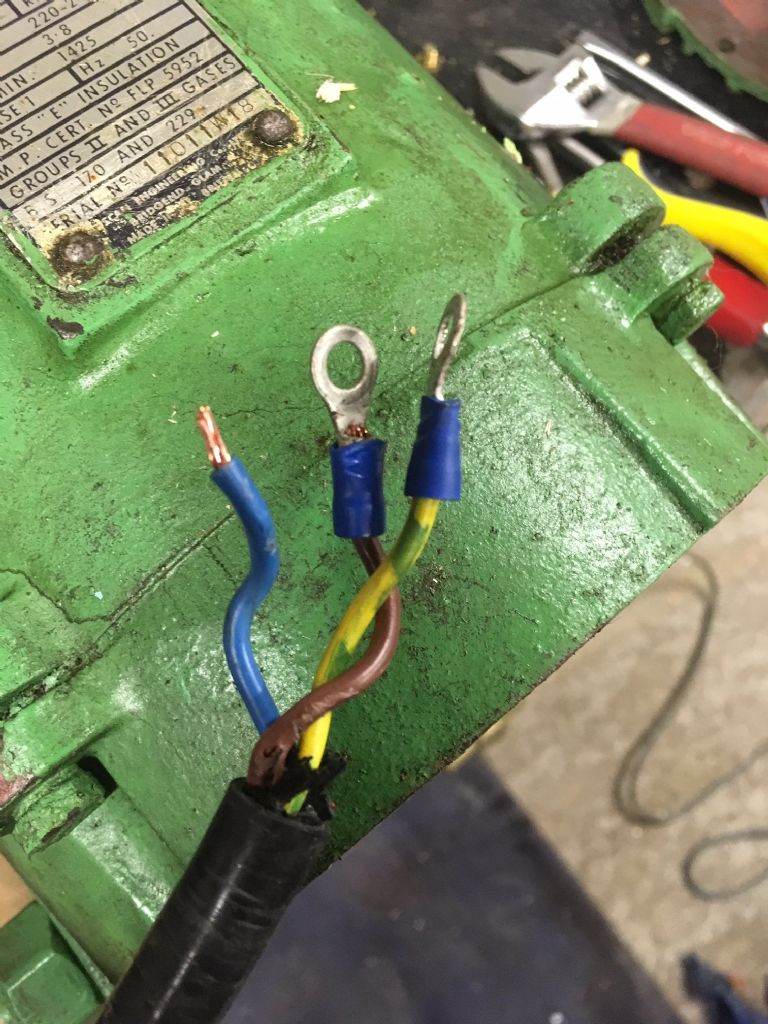

If the terminal is properly crimped, you should never solder it – The crimp is gas tight on its own, and soldering results in the solder creeping up the wire away from the crimp. This stiffens the wire at the crimp connection. When fitting the lug to the intended spot, dressing the cables then often results in difficulty in bending the wire, or excessive force results in fractures in the individual copper wires in the cable. Certainly a total no-no in the Mil-Spec environment, but then our shops are a lot more lax I guess..

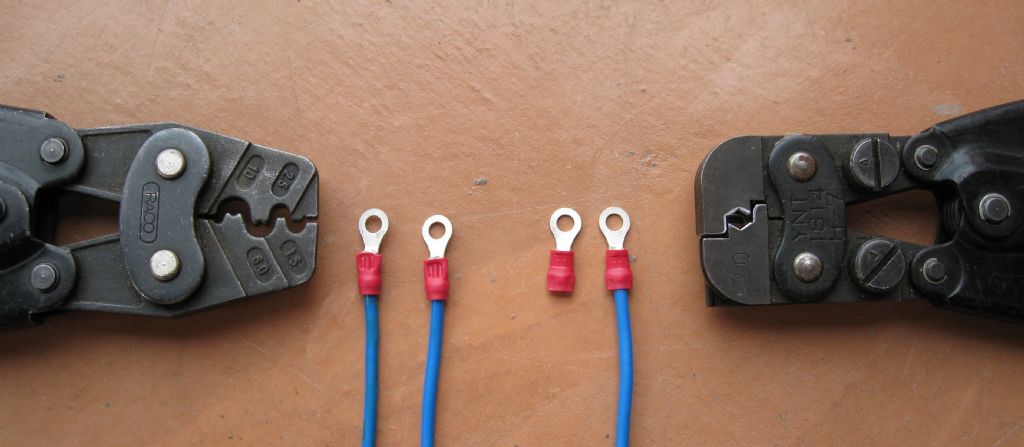

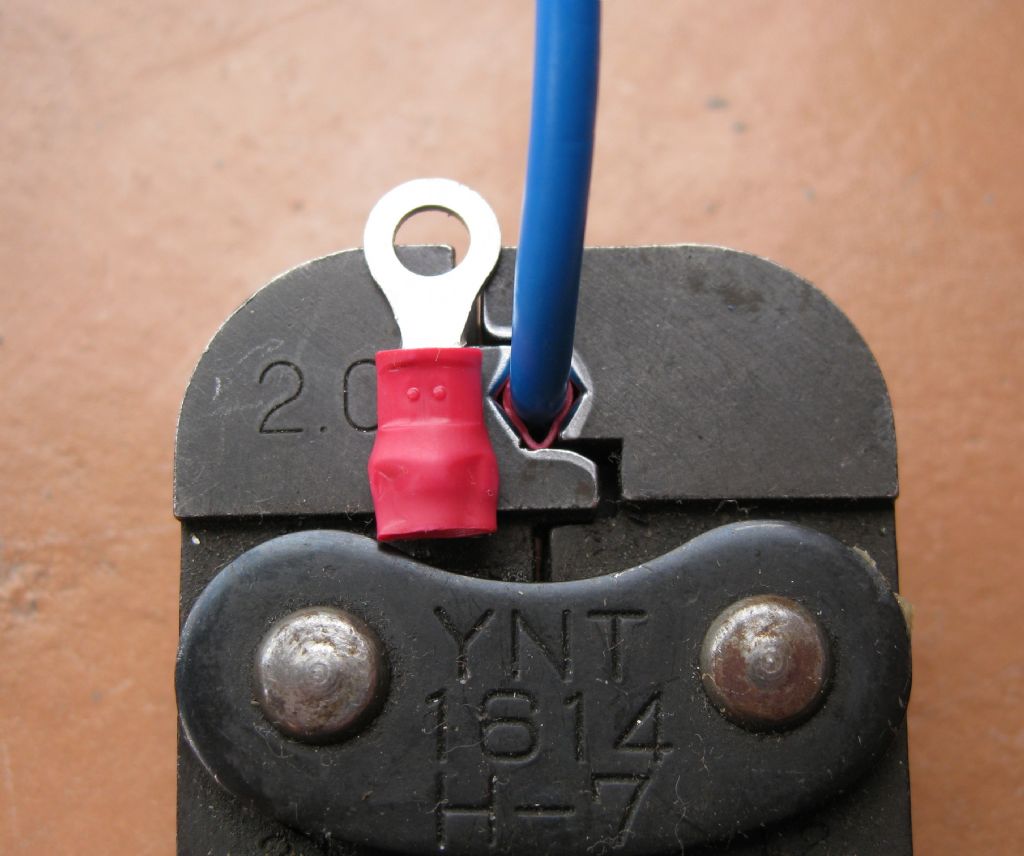

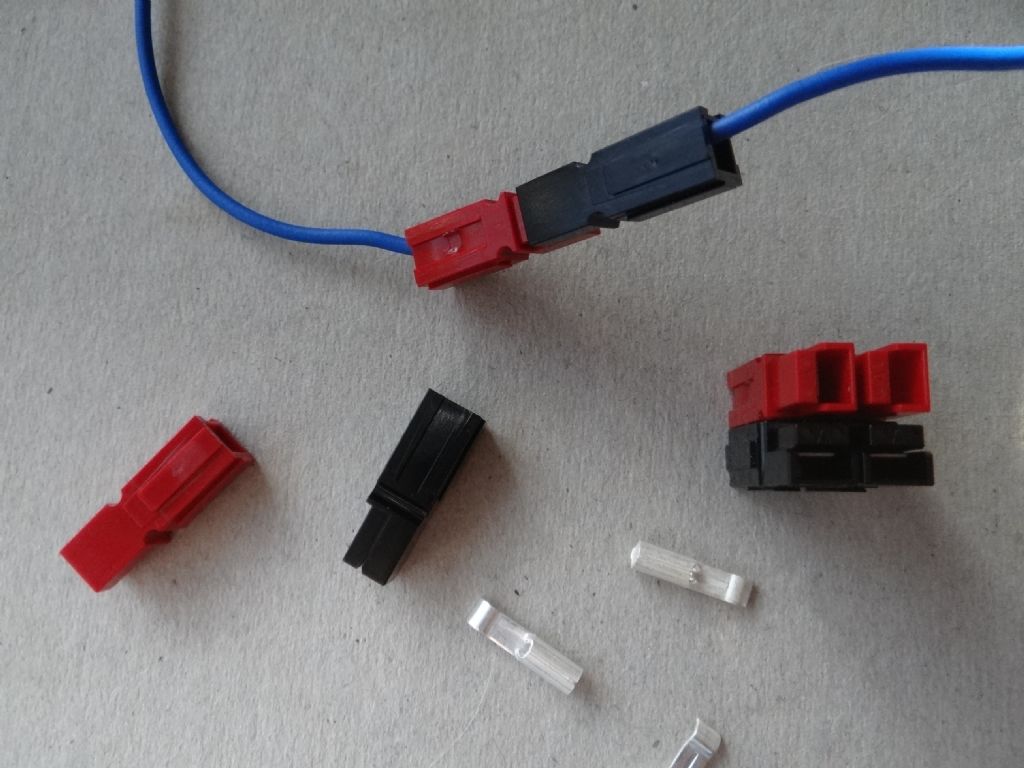

Anyway, here are some photos of good and better crimps..The second is typical of the Mil environment. The plastic shroud on the lug is itself crimped over the wire insulation, affording some strain-relief to the crimped copper section. The first crimper, typical of a 'good' quality commercial crimper does not crimp the rear shroud section, but the joint is sound, and if the wire fitting is sound, the crimp is as good as the second one.

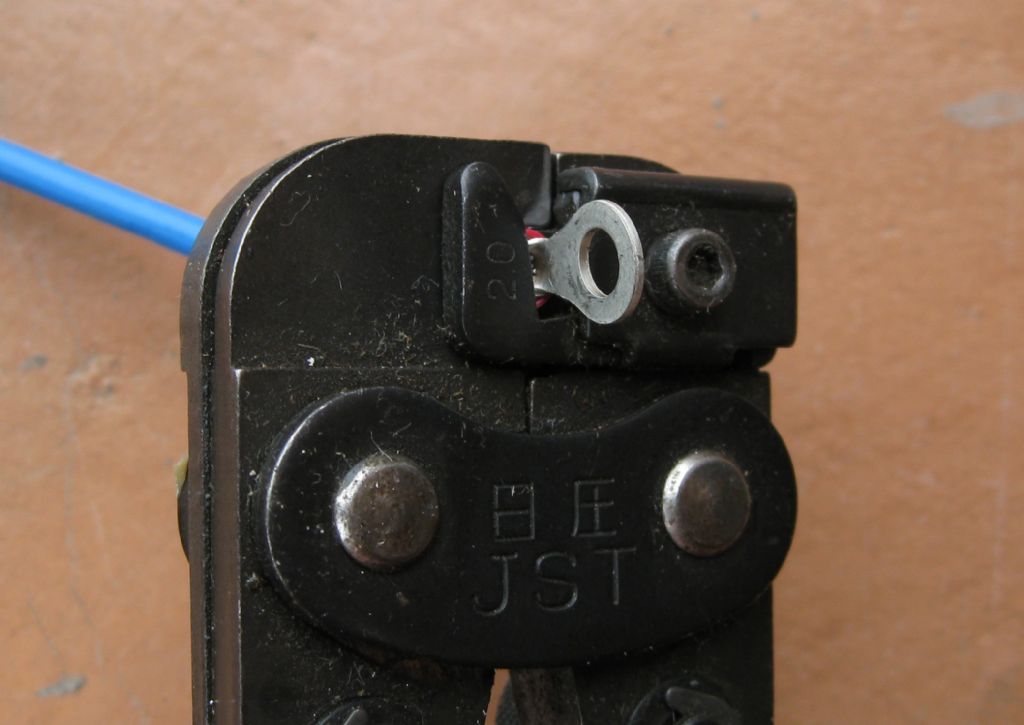

Commercial crimper on the left ( not a pressed steel type, or at least the jaws are not)

The 'Mil' crimper…It has built-in mechanisms to ensure the wire penetrates the lug the correct amount, and that the lug is positioned properly in the crimper, ensuring the crimp jaws impact the lug at the correct spot.

The other side of the crimper – with a sample crimp, showing the two dots on the plastic shroud – these two dots are for inspection and show that the lug was in the correct position, and the pressure correct. If a lug of to small a size were used for the selected crimper, the two dots would not form. Also nicely seen , the wire end of the shround on the lug shows the over-crimp.

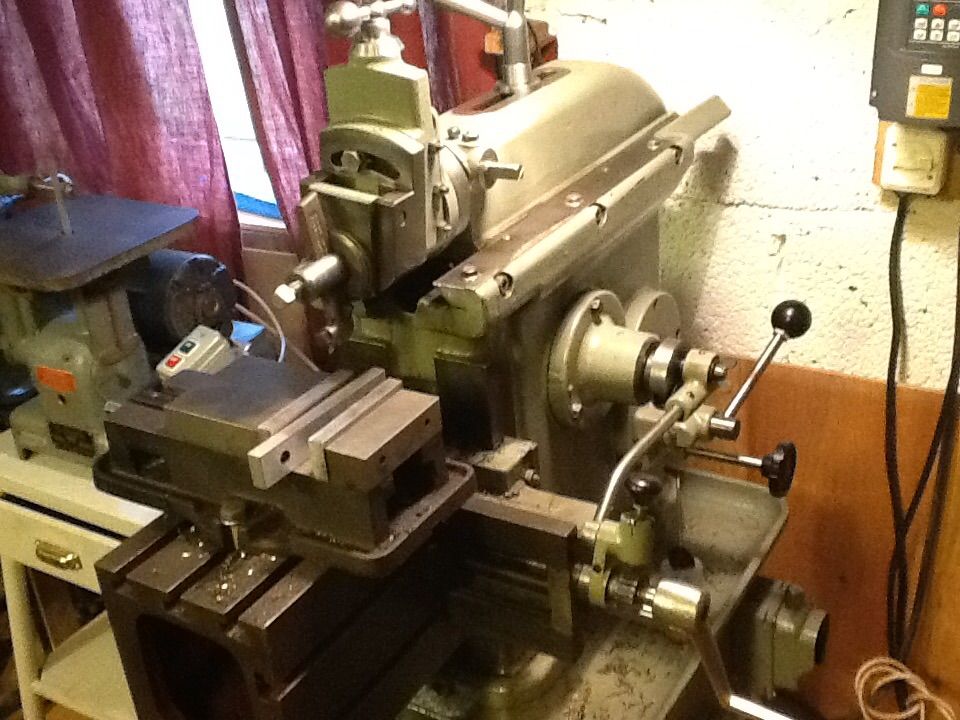

Not a lot to do with Shapers, but..

Joe

vintage engineer.