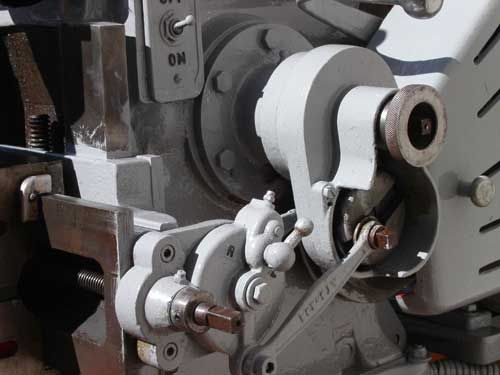

The pale straw idea is about right for high speed steel tooling. You can use carbide tooling too, in which case having the chips come off blue and smoking is perfectly acceptable. I use some uncoated carbide tips, brazed onto key steel shanks. They are the sort with no hole and no top rake, eg a flat triangle shape. I sharpen them with a diamond wheel. I don't know what the grade of carbide is since they were being given away at the club. The guy who donated them said they had been trying them at work for turning and found them useless, but they are fine on the shaper.

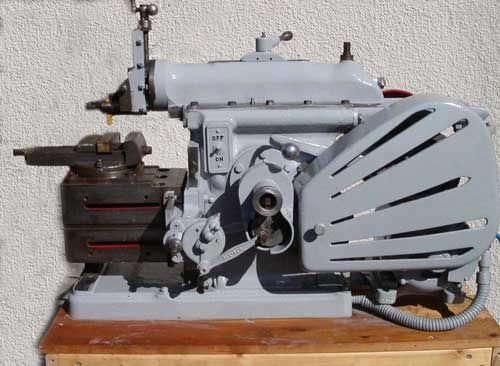

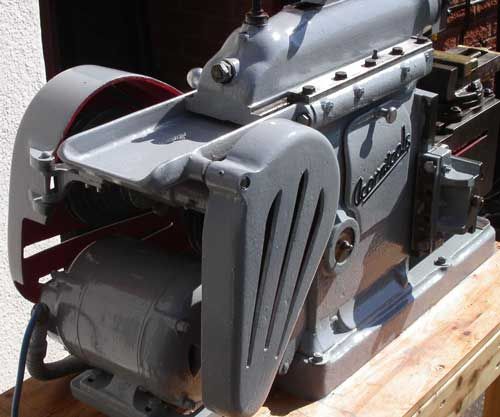

I have had a chip fly out and land in the little hollow at the bottom of my neck, not too much fun! The 18 inch Alba can take a quarter of an inch off cast iron in a single pass with ease.

Shapers should not be compared with a vertical mill, the real comparison is with a horizontal mill. The horizontal mill can give a similar finish, but the cutters to do so are much more expensive. My Alba can do a flat face 18 inches wide with a single very cheap tool…the stack of cutters for a horizontal mill to do that would be much more expensive to buy and much trickier to get sharpened. The horizontal mill is of course much faster, and given a suitable set of cutters, can mass produce jobs with slots, chamfers and so on in one pass, a lot faster than a shaper would. The cost of the cutters matters a lot less when they are spread over many jobs. So for mass production there is no question, and industry has gone for milling machines. For an amateur, the economics are very different, and there is much to be said for a shaper.

Are they dangerous? Well, all machine tools are dangerous to some degree, and I think I fear the woodworking tools in my workshop the most. The danger with shapers is I think partly that the ram seems to be moving at a leisurely pace, and guys are tempted to do things like wipe the loose chips off the job with a spare hand. Do not do this…if you must, use a brush with a long handle. You should usually be working from beside the machine so are not too much in the line of fire of anything that comes loose.

John

vintage engineer.

. Use it all the time. Only 2 regrets,

. Use it all the time. Only 2 regrets,