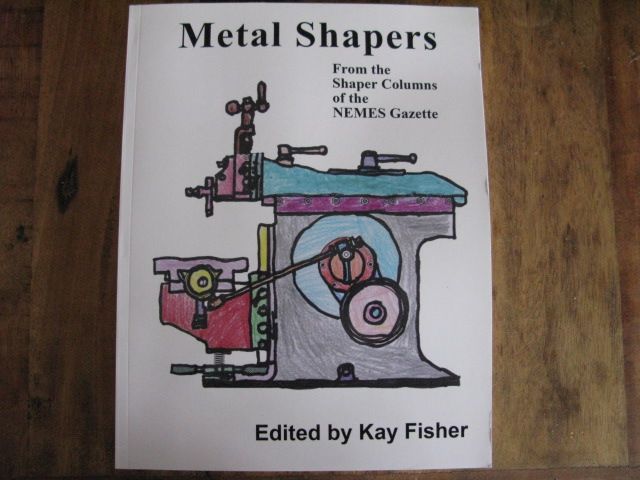

Entirely agree that a shaper, and power hacksaw, are really valuable in the home or one guy/gal on their own workshop.

Relatively low cutting speed makes them totally, utterly, hopeless obsolete in a proper commercial workshop or factory but for the solo user their ability to be left to get on with the job makes them pearls beyond price. Even more attractive given the low market price. I pretty much never find myself waiting for my Elliott 10M (or Rapidor Manchester hacksaw) to finish and all the time they are chomping away is time won to get on with something else.

My things to do list has gotten maybe 20 years ahead of my available time to do it in by now so every little helps.

OK wiz-bang modern CNC with auto- load et al can do in minutes what my shaper and saw can do in the same number of hours. But leaving out the un-affordability factor there seems no difference between having a machine stand idle for 59 minutes until I'm ready for the bit its just done or having the part ready about 2 minutes before I need it.

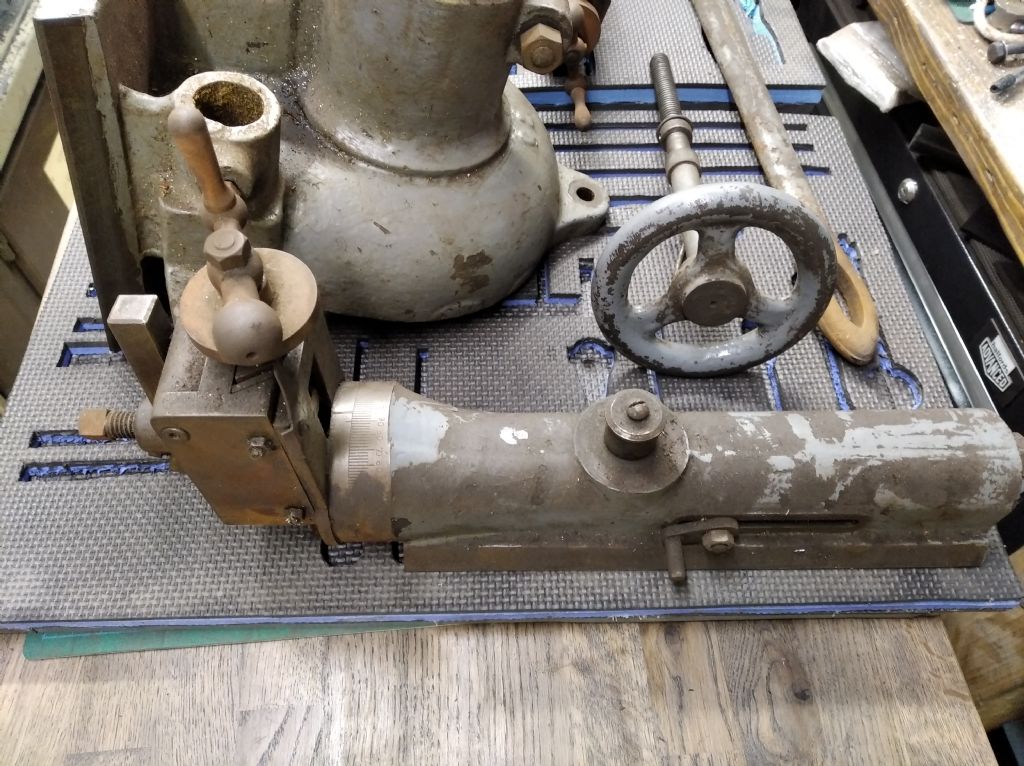

My little Elliott gets regular use trimming stock or "found material" down to size ready for finish operation on the Bridgeport or drill. Chomping mill scale and hard casting surfaces off eats tooling so the shaper is far more economical than the mill in that respect. Its ability to casually leave a surface finish that polishing would spoil given well sharp tooling and half way co-operative material is more than a little endearing too.

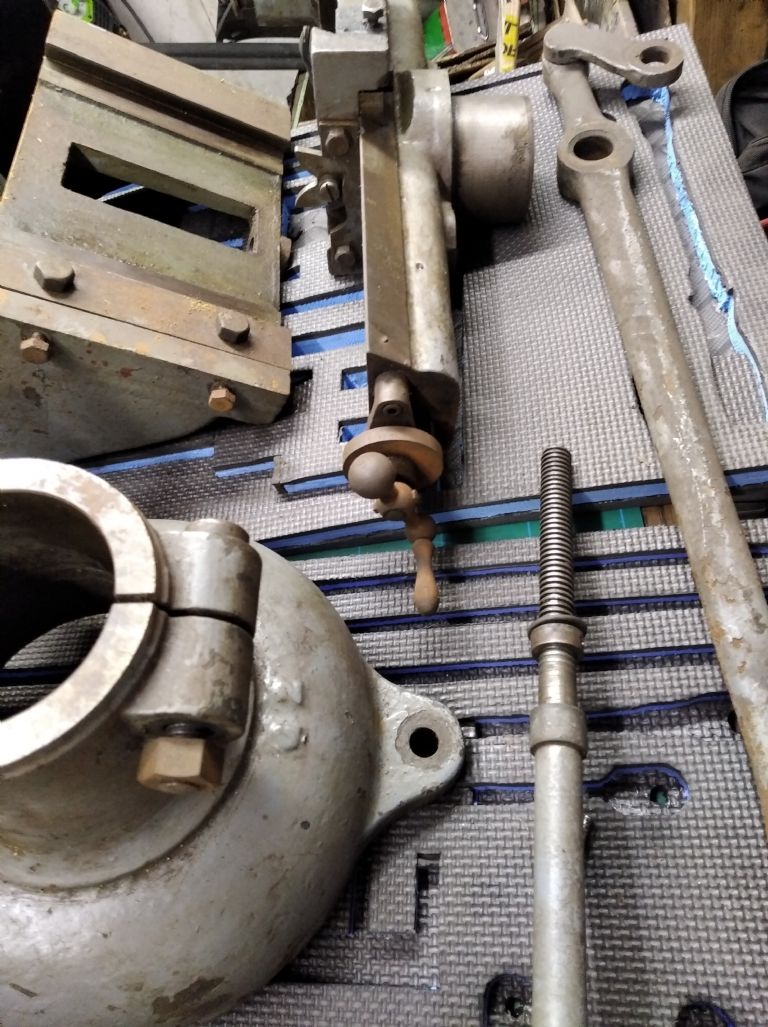

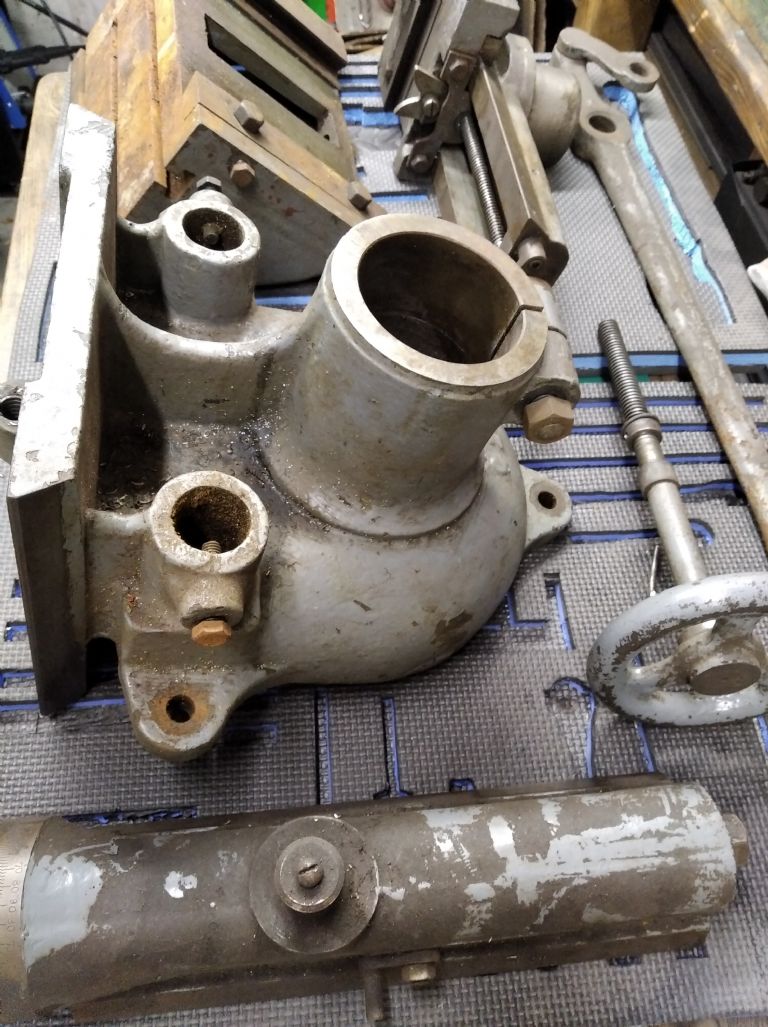

I do need to figure out how to add cutting oil / coolant dispensing to it tho'. I have around 10 ft of 10" x 1" nominal steel bar in stock of a number of projects that absolutely isn't the material I ordered. Drills fine but won't take any sort of finish when machined dry. Whether on mill or shaper. The Bridgeport has a Bjur system which sorts the issue, still hard on cutters, and hand squirting works for the shaper but rather defeats the object of letting it run un-attended.

I imagine a little pump or gravity feed tap delivering via a tube just in front of the tool during the actual cutting part of the stroke would do me just fine. Are there any designs floating around? Looks to me that such is one of those more complex than it sounds project with a good deal of subtlety to getting it working well.

My Elliott runs of a VFD so another somewhen project is to add a microswitch to stop it at the end of the job via the VFD remote input. I know it's safe to let the beast run up to the end of travel but it's inelegant to have it sitting there running in air cutting mode until I can get to it. I guess a modern magnet would hold a switch just fine.

Clive

Edited By Clive Foster on 12/09/2023 09:03:16

vintage engineer.