Posted by Buffer on 18/06/2021 16:30:41:

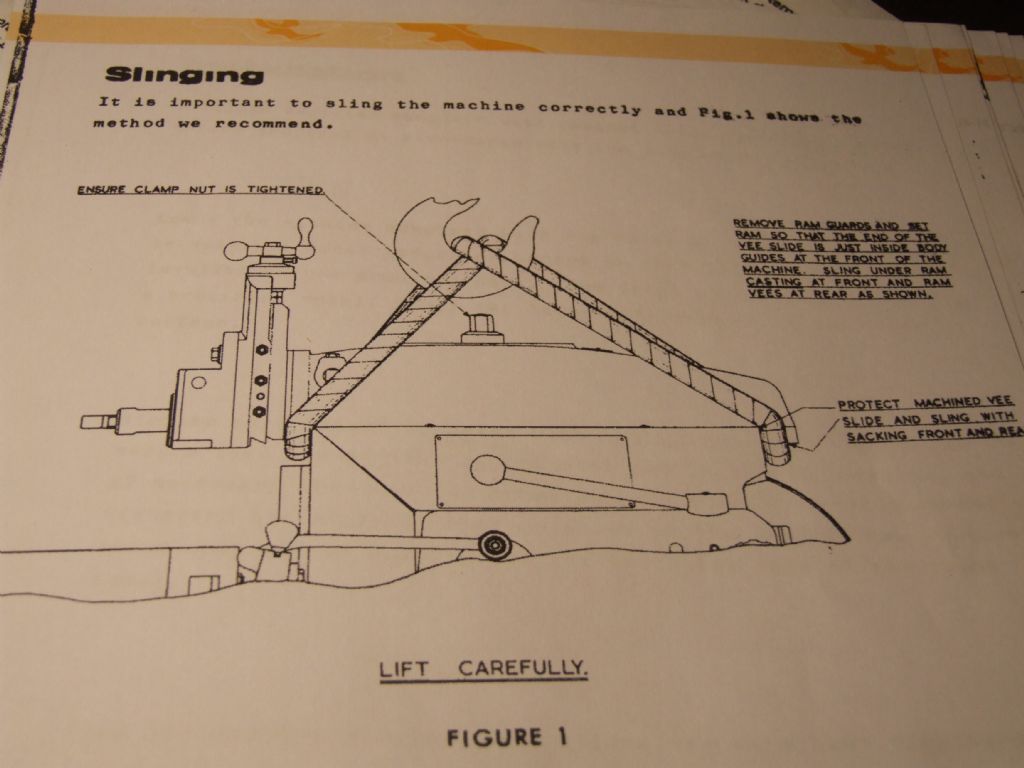

I have a Tom senior mill and a shaper. The shaper is very slow compared to a mill.

Generally true, but it would depend on the type and size of the milling machine and Shaper… William does not specify which Tom Senior – digging on Google, there seems to be a few variants? – the M1 might move metal faster than most shapers, but I am not even sure of that, if referenced to say an ALBA 2S or Elliot 14M shaper, both types in a number of hobby shops… The Senior E type certainly will not…

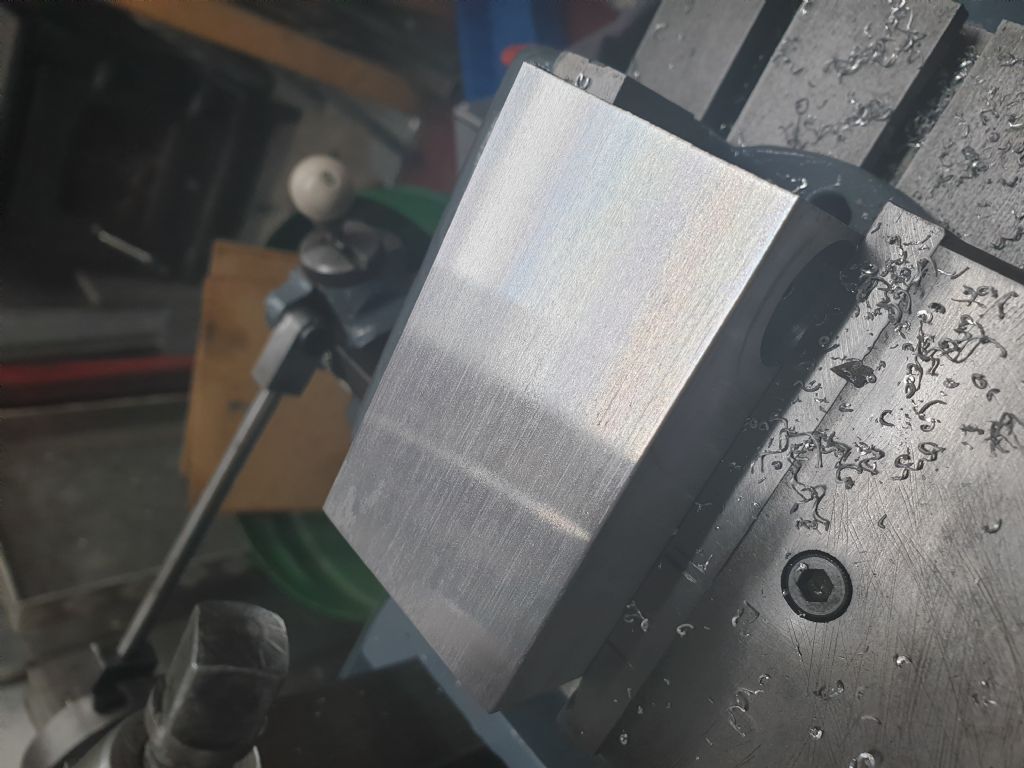

My ALBA 2S can take slice a chip of cross section 3×1.5mm in mild steel without burping. And it will do that over a 300mm length in a few seconds- No way I can do that on my bench top mill..I don't agree about it being difficult to find an edge on the workpiece – very easy – use a sliver of the proverbial fag paper and wind the cross slide up to the cutter till the paper is snagged – many folk do that on the mill!

Also, the cutters for the shapers are much easier to make and much cheaper than endmills of big-cut capability. And easy to sharpen. And you can even use them in the lathe..

I would not be without my Shaper if I can help it! But, I could not do without my benchtop mill either!.

I think there is a balance – if you can afford a big mill with heft capability, you can probably afford the cost of tooling it – collets, cutters ( HSS, Carbide, ) etc then a Shaper is moot. But if you can't, a shaper is an inexpensive solution to hogging metal in preparation for finer work on the small mill.

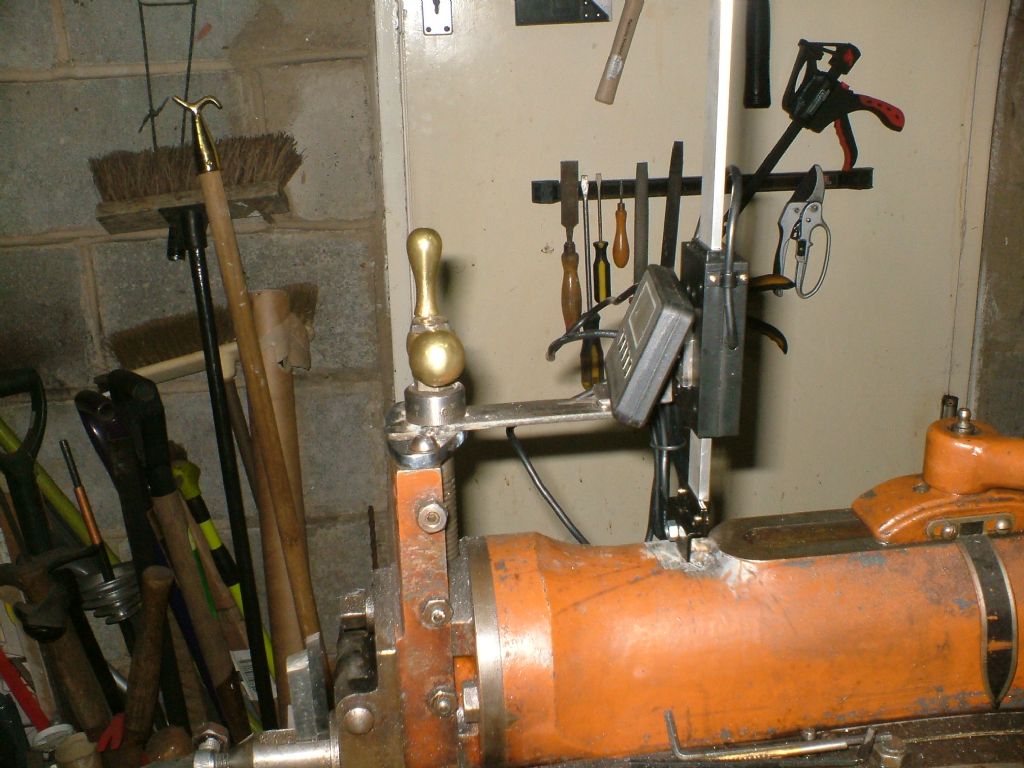

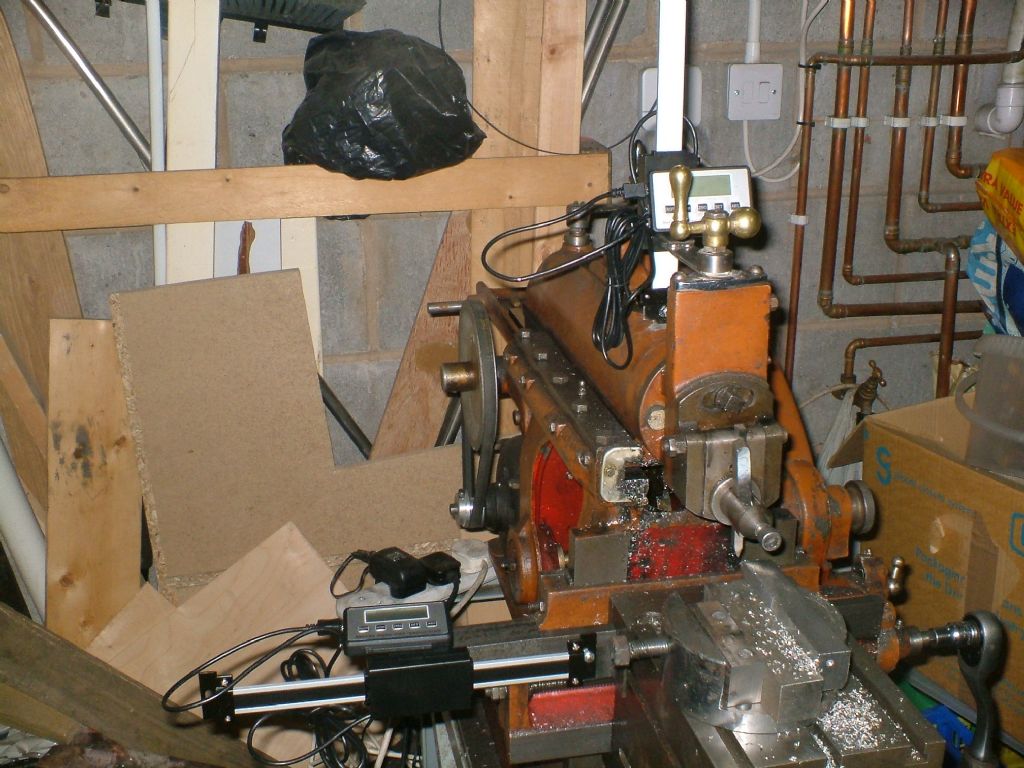

And since DRO's are mentioned – if you fit a DRO to the shaper, you will be amazed at how accurate you can work.

Joe

Edited By Joseph Noci 1 on 19/06/2021 10:43:54

vintage engineer.

or a shaper, couldn't it? That's not something a mill can do that a shaper can't, right?

or a shaper, couldn't it? That's not something a mill can do that a shaper can't, right?