Thanks everyoner for all the comments.

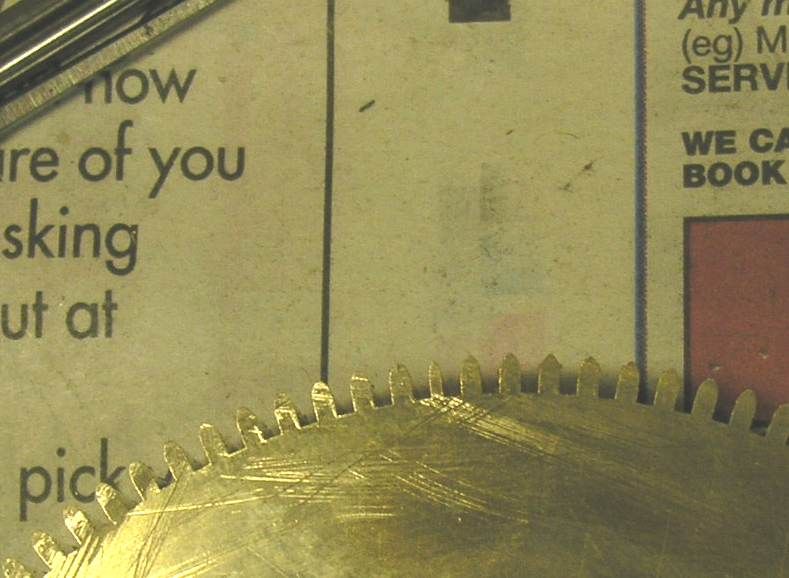

Just measured the teeth and they are of equal thickness apart from the thin one. We thought of using dividers to check the division plate but felt that it would be easier and more accurate using the BW Electronics DRO and wind the cord from it around the 3 jaw chuck. Went round the plate twice but could not find any error of more than a thou or two between the holes.

I like the direct indexing as there is less chance of making a mistake and you can feel as well as hear the dentent going into the plate. It is dead tight with no slipping/backlash anywhere.

Did not see the problem when I took the cut wheel from the mandrel as I was quite pleased at how good it looked, must clean my glasses more often.

Just cut a disc to do a trial, pondering it I should make it slightly larger or the dead size from the formula.

Next time I will examine the blank before removing it from the mandrel so that I can see where the thin tooth lines up with the plate—if there is a thin tooth!

Peter

Michael Gilligan.

Michael Gilligan.