Thats a double or triple pattern with only one knurl doing any work.

Things to check :-

Is the material suitable? Anything that has work hardening tendencies will be hard to knurl at home. In general stainless steels can only be reliably and satisfactorily knurled using the cut knurling system.

Are the knurls sharp?

Do the knurls spin freely under load?

Is your knurling tool strong enough to apply enough force to the job and rigid enough to keep the knurls correctly aligned?

Is your knurling tool set up properly to pinch on the centre line of the job with the knurls aligned with the lathe axis?

The sample looks as if the knurls are out of line with the lathe axis and the tool is sufficiently flexible to let the ineffective knurl skid sideways.

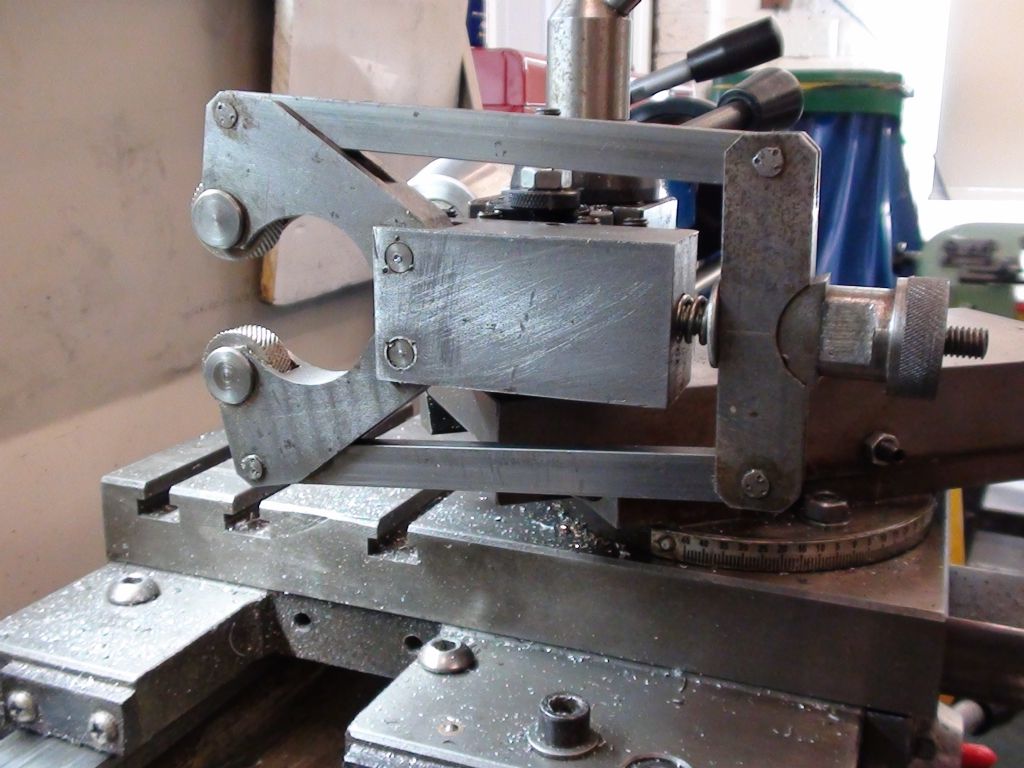

Knurling using conventional push knurls is pretty brutal process. Considerable force and rigid tooling is needed if things are to just work. I have a hefty Marlco clamp knurler and ex-industrial machines. Even then the process is not always routine. It's very important tha the forces between the knurls are balanced. If I have issues its generally because I've gotten rush headed and not set things up balanced.

Although plenty of people have gotten good results from clamp and even push knurling on smaller machines my view is that the three wheel, hand squeezed "nutcracker" type is far more reliable on smaller lathes. Being hand operated you can feel whats going on. Its obvious when things aren't going well.

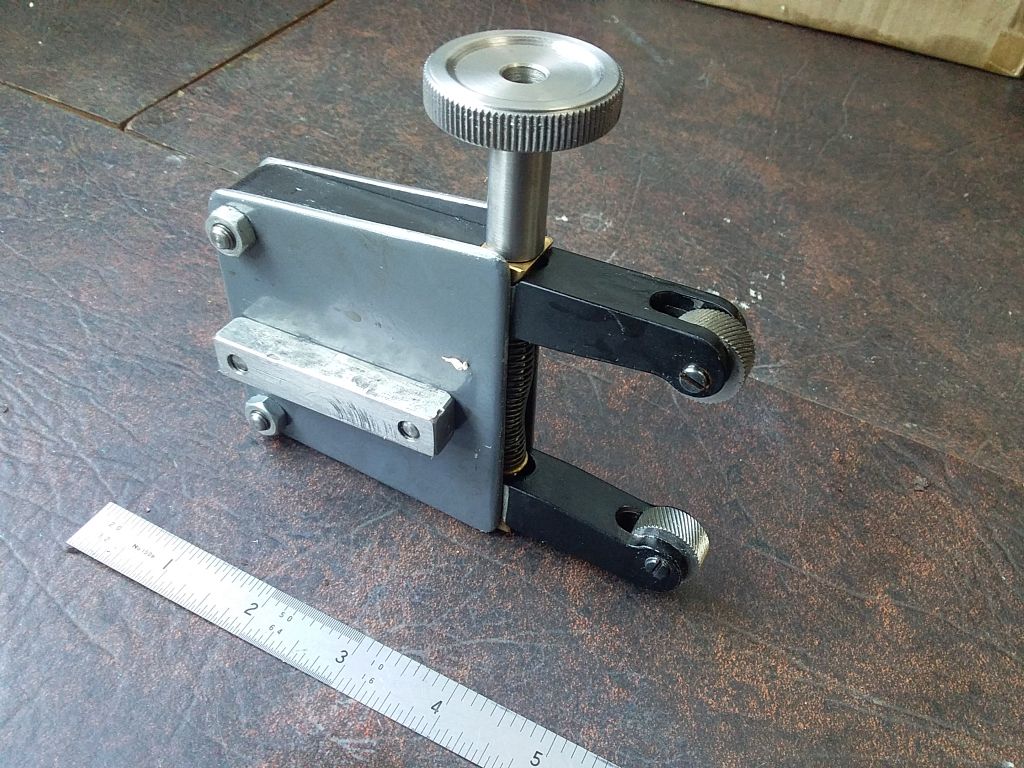

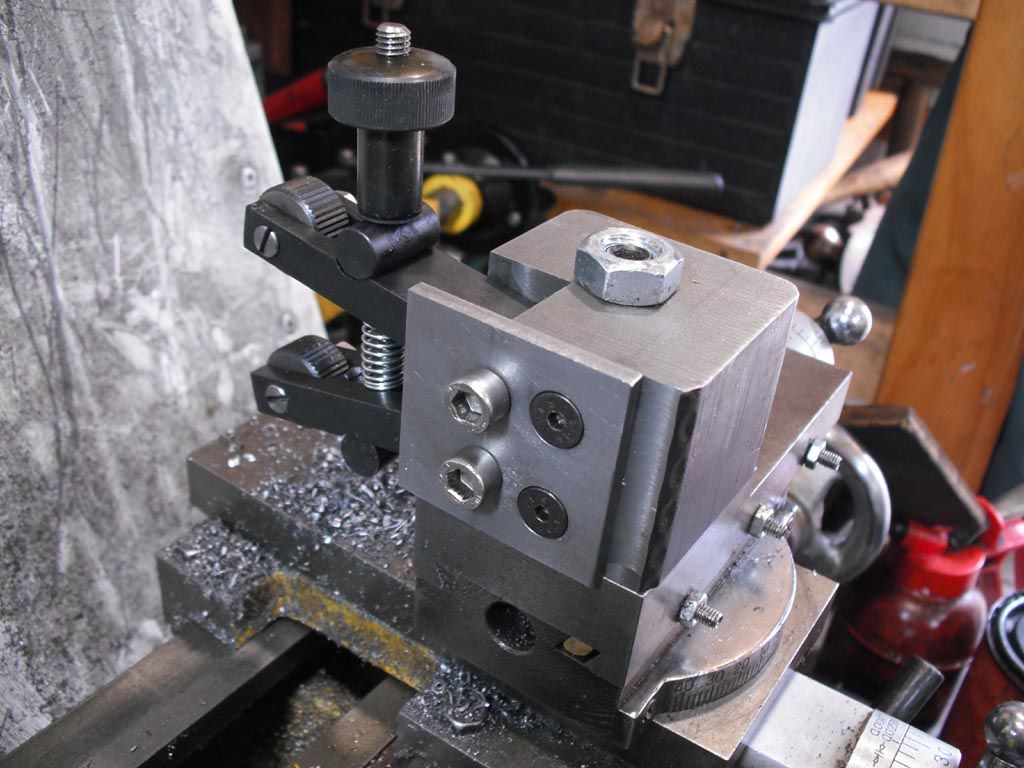

Here is picture of mine.

Bought when I was driving SouthBend 9" it instantly solved my knurling woes. The 9" Southbend is sturdy enough to make a decent stab at clamp knurling with a lighter weight tool or even push knurling but it always took a bit of experimenting to get good results. Even then there were failures where the job just point blank refused.

It's noticeable that people who report good results with clamp knurling on smaller machines, our esteemed MEW editor for one, tend to use tools with short stiff arms. Commercial variants all seem to have the arms too far apart and too long for optimum stiffness. Once you can get a knurl started and flowing the process goes well. Its the initial getting going where any limitations of stiffness show up.

Clive

PS Am I correct in recalling that you have a Pultra? Although this is one of the sturdiest of the very small machines, knurling is really expecting a boy to do a mans work. Precise technique and excellent tooling will be essential.

Edited By Clive Foster on 10/03/2023 19:26:51

Martin Johnson 1.