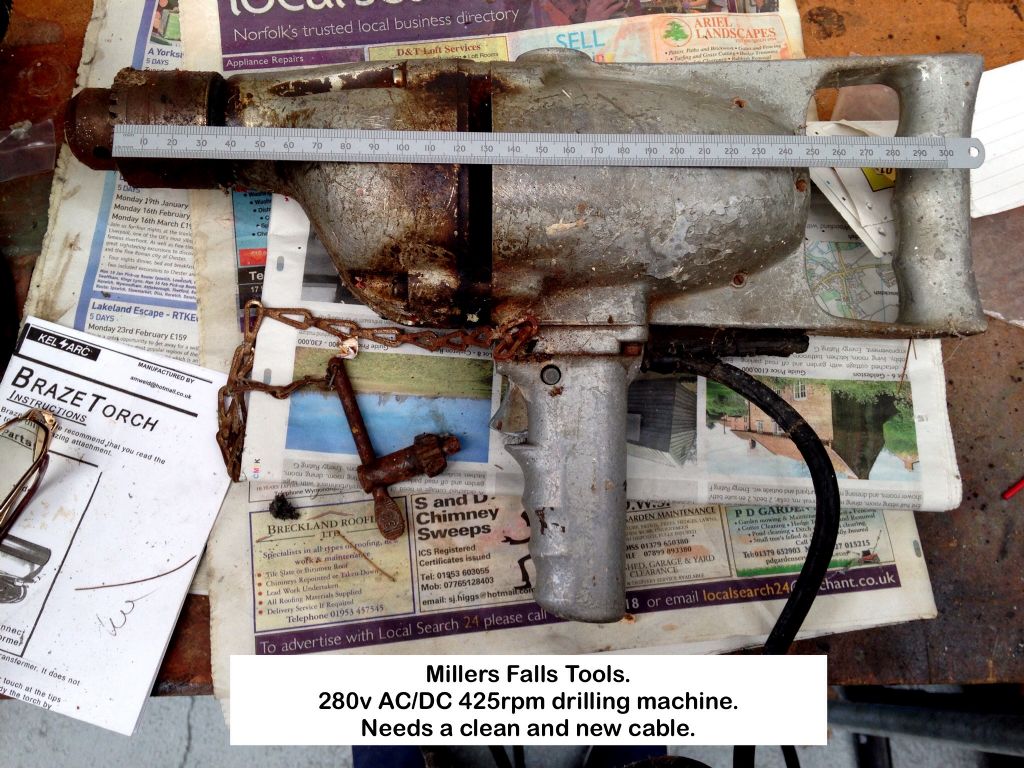

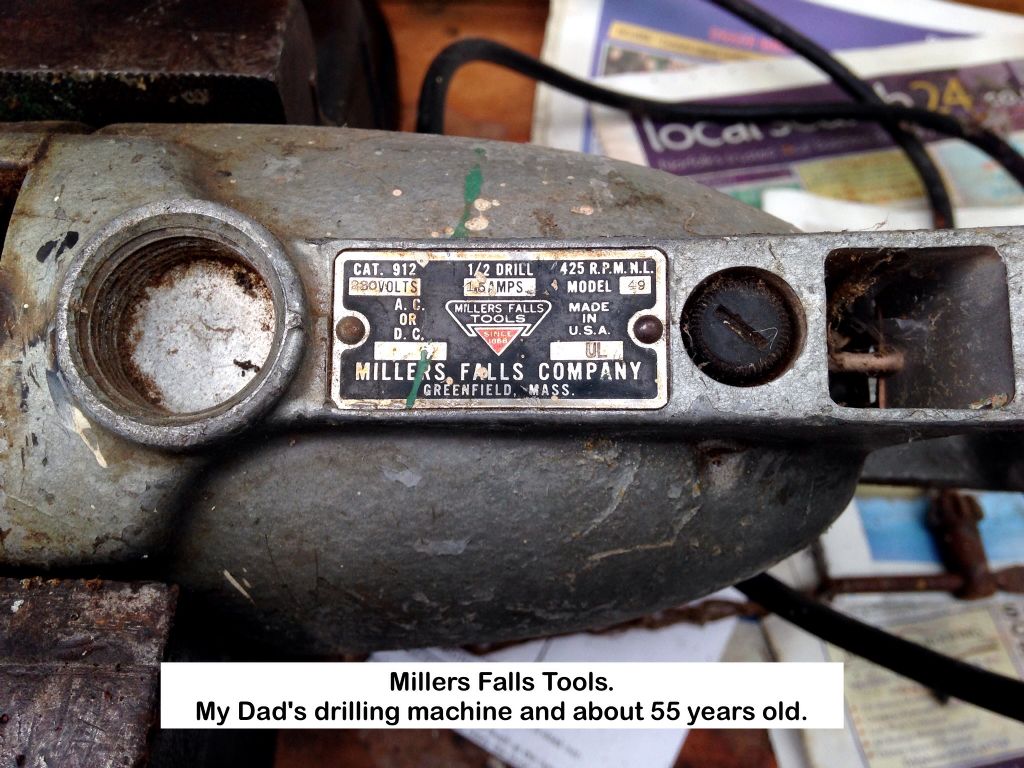

I used drills like this while serving my apprenticeship as an electrical engineer in the early seventies. here are the ups and downs.

They are very powerfull, slow and low geared, which means they will quite happily twist the operator round if the drill bit stops!

They are incredibly heavy, tiring to use, but the weight means it will drill a hole without having to push very hard.

They need an experienced and strong user who is not afraid of the thing!

They are all metal, and despite what has been said above, virtually impossible to double insulate, so they must be earthed, although the 110v transforer does, as also mentioned above, reduce the shock voltage to 55v, I would also use this tool with a RCD type trip if at all possible.

Having said all that they are built like tanks, and are virtually bulletproof, due to the fact that it virtually impossible to overload the motor, due to the gearing.

I would fit a proper 110v plug to it, Check the carbon brushes, check the continuity of earthing all the way to the case of the tool, do a megger or PAT test at 500v to check the insulation WITH THE TRIGGER SWITCH IN THE ON POSITION, and if all is ok, test it on the transformer. These drills do very well when fitted into a stand and used as a pillar drill, but with the price of power tools today, they are precious little use for anything else, although there is probably enough aluminium in the case to build a jumbo jet!

Phil

Stuart Bridger.