Like many others among you, I bought a couple of lengths of the excellent bronze bar from Jason Udall. I thought it might be interesting to invite you to share any interesting things you did with it – if nothing else, it would be nice for Jason to know that he wasn't wasting his time.

In fairness, I'd better start. The only thing I have had time to do so far was to make a roller for an anomalous climbing novelty.

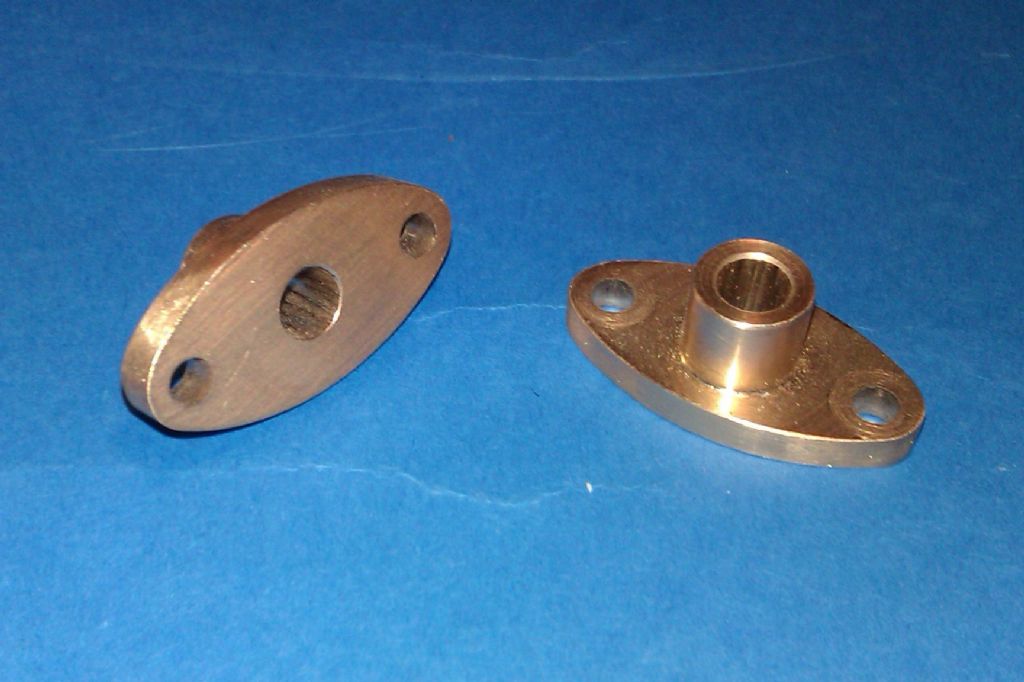

The double cone was of course made by sticking two cones together. The cones have an included angle of 40 degrees. I was a little concerned about how to locate them; then I realised that there was a nice 1.03 mm pip left from parting off. I drilled a 25 mm hole in a piece of softwood with a wood bit, which was just enough to hold one cone to drill a 1.1 mm hole. Glued with Araldite, baked in oven at 65 degrees for an hour, which made it harder than I would have wished and was a b****r to clean off.

The lash up in the first picture is just to work out the necessary settings to enable the cones to roll "upwards"; broadly making the two bars (silver steel in this rig) diverge more is positive, increasing the slope is obviously negative. You either have to work out the maths or do it by trial and error. I have embarked on making a nice oak stand with stainless steel bars.

Bronze is ideal for this purpose; it turns well, looks nice and does not stain badly. Brass would need to be varnished to avoid this, or be polished every few days, and I think varnish would not help the rolling.

David

Edited By David Littlewood on 09/01/2013 19:41:18

jason udall.