Posted by SillyOldDuffer on 06/01/2022 11:28:37:

Posted by John Smith 47 on 05/01/2022 19:09:49:

Posted by Neil Wyatt on 05/01/2022 15:02:37:

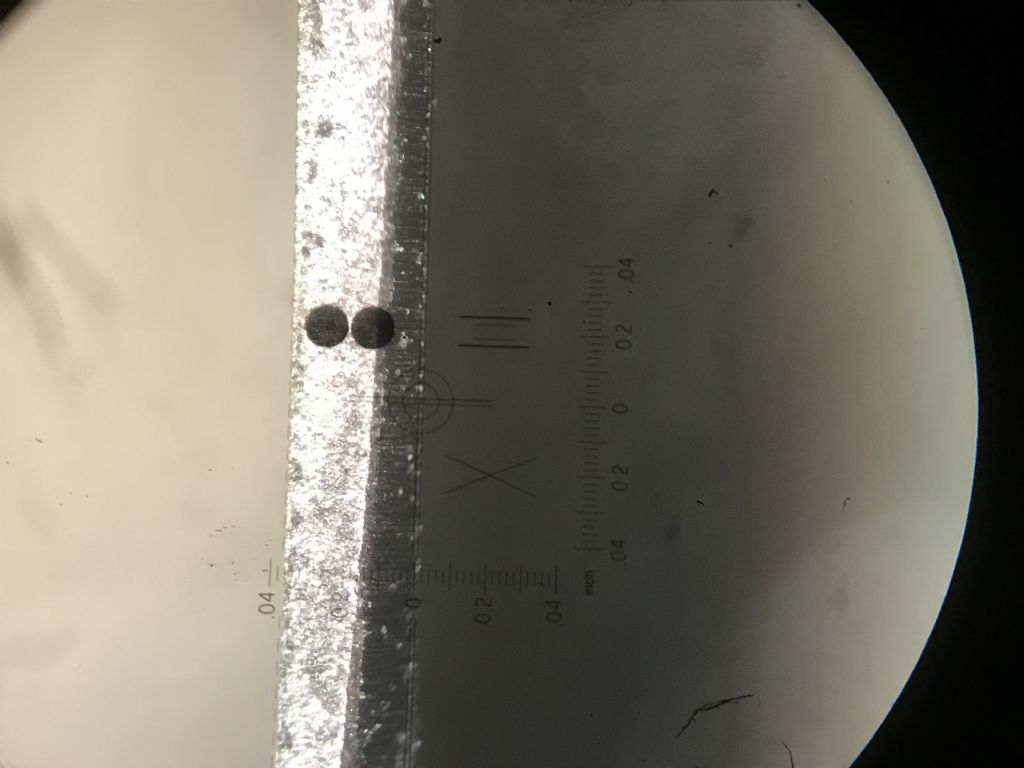

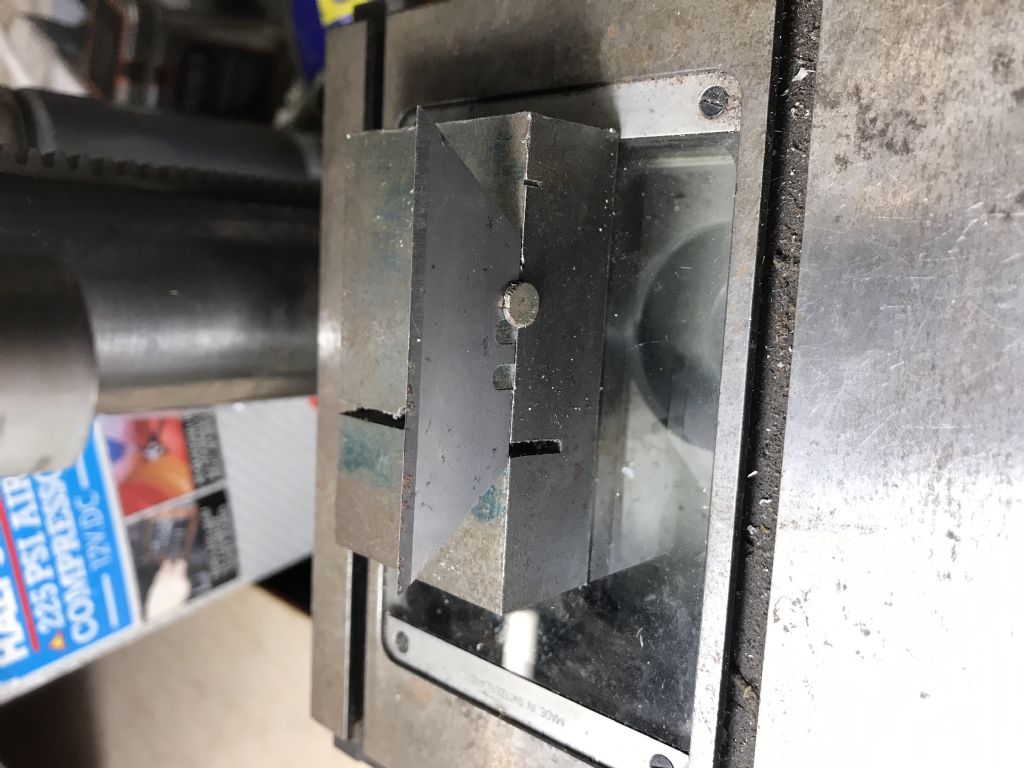

Did anyone suggest taking an impression of the corner using plasticine or blu tack, then selecting a drill that's a good fit in the impression?

Neil

No, but nice try.

The trouble is that faces are at 90° to each other. i.e. The arc of the radius on the fillet is also only 90°, so it will be slightly hard to determine where or not the drill is fitting snugly into what is only a 90° corner.

Being 'hard to determine where or not' is a problem common to all measuring techniques, and the cost of getting better answers shoots up scary fast. As space and money are always constrained, it's important to focus.

Only you can answer the question 'how accurate does the measurement need to be?' and 'how much time and money am I prepared to spend'. Until this is clear, you are wasting your time because most of the candidates are off the table. The most accurate methods involve expensive bulky equipment requiring a skilled operator who takes many careful measurements and then analyses the results.

If simple methods like eye-balling and the plasticine trick aren't good enough, then the answer is going to cost money. If money is short, think carefully. You certainly mustn't waste £15 on a Starratt Gauge, or £60 on a Digital Radius Caliper that won't do the job either!

From what you've said of your prototype, it seems unlikely that this radius needs to be measured at all!

Have you thought of dodging all these confusing measuring and practical problems by developing your prototype in 3D-CAD? Being drawn by mathematical formula, CAD Radii and other parts are perfect, with no tool-marks or other inaccuracies, and the dimensions are absolutely trustworthy. No need to measure them.

At the initial design stage, it's advantageous not to bog down in practical details that might not matter. Changing manual 2D drawings is so expensive, old-school Draughtsmen were encouraged to design with production in mind. You don't have to do that. These days, more likely the CAD model will be amended in a separate design review by a Production Engineer. They specialise in making things economically, and are brutal pragmatists. Be warned, they often shoot all the inventor's sacred cows!

Dave

Dave in the nicest possible way… I have not told you every single detail about what I am doing.

> From what you've said of your prototype, it seems unlikely that this radius needs to be measured at all!

You don't KNOW that. And even if true, it is arguably none of your business. I know you meant to be helpful but I am struggling not find that comment both invasive and quite offensive.

Look, I am not building a space rocket, but what I am doing is quite complex, and involves a balanced judgement between competing issues. Even if it were IP appropriate, all of this would take too long to go into, and would be a waste of your time and mine.

Where I have a specific question, I ask it. And yes, almost all of the advice given the framing of the question that I have provide HAS been excellent.. and yet, even whilst it engages, interests /amuses some users, the mere existence of the whole damned conversation seems to irritate various users.

Maybe they are jealous of the attention, I don't know. And if so, sorry but that's simply not my problem.

And to be completely honest, talk about wasting of resources, I see this persistent pestering for me for the absolute full details of exactly what I am trying to do, not just a deep waste of my time but also as an attempted to violation of my privacy.

YES, there will always be a bit of banter and a few interesting deviations and weird facts that people bring to the party – all good fun – but the persistent stream of critical patronising advice and endless critical sniping & bitching about my budget, my level of technical experience… my strategic decisions, my motives, my tone, whether & when I do or don't buy some specific product and then taking umbrage if they are ignored… Although I have been pretty self-restrained in my replies… it's EXHAUSTING.

….Is it too much to ask for the nice folks in this forum to just answer the specific questions that I am asking about tools for model-making?

I know that us 'innovators' necessarily are required to develop thick skins not least because you can't please everybody, not ever. We ask 'naive' questions, make endless mistakes, but we learn and more importantly with fresh eyes we see things that others have failed to. It's what we do.

And, please for the love of God, just let me make my own mistakes.

PS Back to tools, yes, of course I am using CAD. Both 2D & 3D software (Xara & OnShape).

Edited By John Smith 47 on 06/01/2022 14:45:39

John Smith 47.