Posted by Lee Jones 6 on 22/05/2020 10:39:22:

Just to clarify, my original question was:

What *should* a Warco Super Major Milling Machine be able to accomplish?

… because that's the machine I have. I just want to know what it can reasonably do.

I'm not in the market for a newer, larger machine.

Sorry Lee, I was trying to rank the Super Major relative to other machines.

The point is all milling machines cut metal, but that powerful rigid machines get results faster and generally make life easier for the operator. In particular it's more difficult to do accurate work with the lighter machines because they flex.

It's not as simple as saying a WM14 can only take light cuts in cheddar while a Super Major will plough through 12" armour plate. Rule of thumb for all machines is 1HP will remove about ¾ of a cubic inch of mild-steel per minute. So in theory an Super Major and a Bridgeport should do about the same amount of work in the same time. BUT a Super Major is lighter and less rigid than a Bridgeport, so in practice the operator has to adjust to maintain the same level of accuracy, because Super Majors bend more than Bridgeports. It doesn't mean a Super Major is a waste of space.

My initial contact with machine tools was discouraging. A combination of carp metal in my junk box and me not understanding tool options, depth of cut, rpm, feed-rate and the need to snug everything up caused the impression the machine was faulty. Not so. Once I got the hang of it, chatter stopped, tools stayed sharp longer, finish improved, and jobs got done faster. Bit like learner drivers mastering a clutch; who didn't start by kangarooing and smoking the clutch on hill-starts. There is nothing wrong with the car, you have to learn to drive it!

You have to get a feel for what a particular machine can do by using it. As a Super Major is a fairly big hobby beast, it's less restrictive than smaller machines like my WM18. But my WM18 does everything I need of it, and a Super Major is 'better' because it's bigger. The main limitation is the size of the table.

A Super Major would come unstuck if used for continuous production. It's sized for intermittent work allowing the motor to cool down, and it's lack of rigidity would cost too much in operator time and skill. But it should do a good job in a home workshop, better than my milling machine and streets ahead of a milling slide on a lathe.

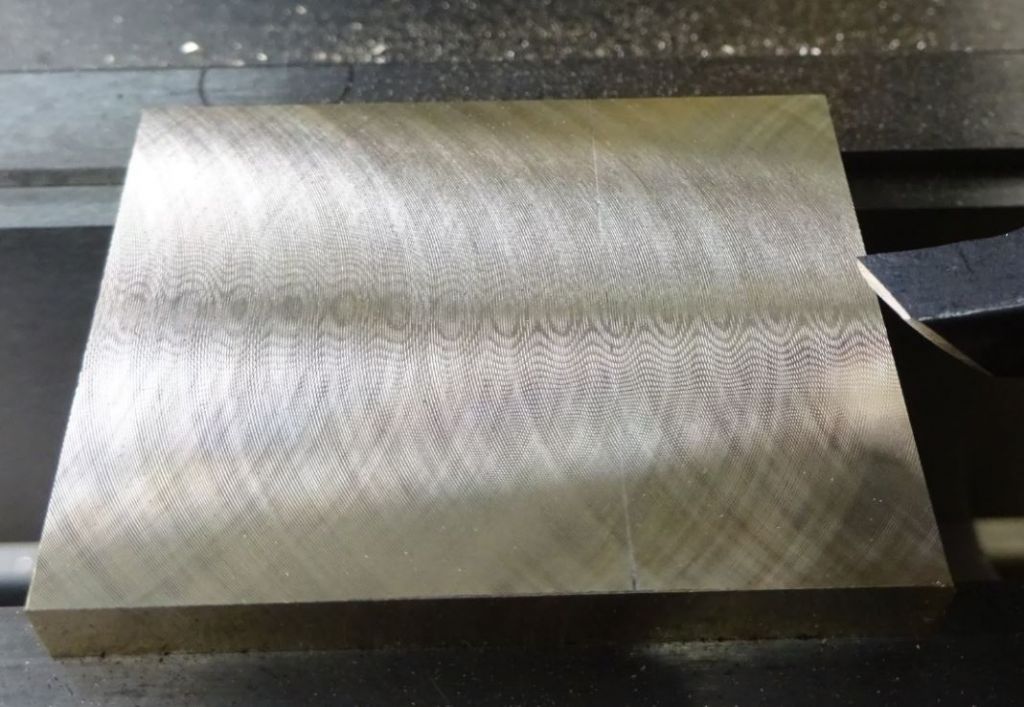

Two common beginner mistakes are pussy-footing and Gorilla expectations. Nervous light cuts blunt tools very quickly. Tools must cut rather than scrape and rub. And beginners persist with blunt tools long after an experienced machinist would have changed them. Mr Gorilla is even worse; he may be brutal enough to damage the machine by overheating the motor and electronics, stripping gears, bending tools and causing excessive wear and tear. And disappointed because finish and accuracy are poor. The ideal is somewhere in the middle; moderately deep fast cuts within the capability of the machine. Let the machine do the work, and have it working hard rather than soft. I do it by ear: having selected a suitable tool and rpm, I adjust depth of cut and or feed rate until the motor is heard to be working without labouring.

Jason Bellamy's recent MEW series on Milling is an excellent introduction. Jason doesn't do anything in his write-up that isn't well within the capabilities of a well adjusted Super Major.

Dave

Tony Pratt 1.