HI,

Having had some time to think about this, I'm veering towards a candlestick. I'm thinking it could even be a Christmas pressie if I get my act together.

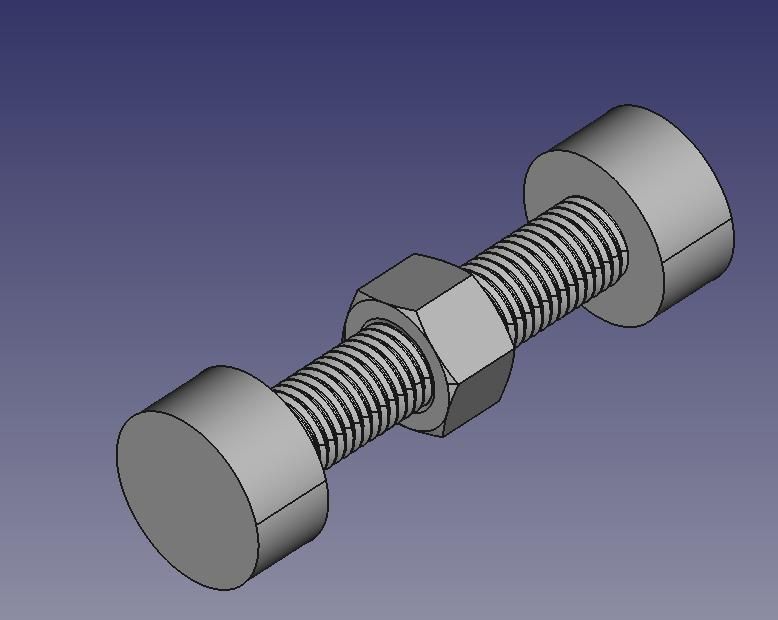

My current thoughts are to make it in steel / ally since I have some stock in my bin. What I thought I'd do was something like this.

Cylinder (100mm) for the base and for the candle holder (might be smaller).

Face off the cylinders and bore to put a (say) 10mm thread in.

For the base cut 3 legs (say 8mm deep) out using the mill and a rotary table.

For both make a mandril to fit the 10mm internal thread and turn the outside.

For the stick part, take 15 – 20 mm round bar, put a step on both ends and an M10 thread to assemble afterwards. Move over the tailstock and turn a nice taper.

I'd definitely make the base of steel (one should try and make it hard for these things to fall over, I'm told).

THere's two things I don't really know how to do. First is that I'd like the base and top to be curved smoothly rather than square. I understand about ball turners and whilst there is a strong temptation to make one, that just puts me back in my making tools to make tools to make…. obsession.

Can I cut some angles and then smooth with a file? Or is there a cleverer way?

The other thing is finish. Brass would be finished by virtue of being brass, but steel probably needs a coating of some kind? I'm also not sure what I need to do to get a burnished or mirror finish. I guess it's a lot of sanding with increasingly fine paper and then the dremel with some rouge and a buffing wheel?

I'm afraid that I've been focusing so far on stuff that's functional. Pretty is a bit daunting!

Any advice (as always) very welcome.

Iain

Iain Downs.

for making flat cakes and pastries (pizza etc.) for all family members. I had some old aluminium tubing, and used ball bearings for easy rotation. It was completed with a hardwood stand. It is a pleasure to use, and only needs a simple cleaning with a moist cloth.

for making flat cakes and pastries (pizza etc.) for all family members. I had some old aluminium tubing, and used ball bearings for easy rotation. It was completed with a hardwood stand. It is a pleasure to use, and only needs a simple cleaning with a moist cloth.