There are several families of stainless steels with different physical properties. The magnetic properties of stainless steel are very dependent on the elements added into the alloy. A basic stainless steel has a ‘ferritic’ structure and is magnetic, formed from the addition of chromium – it can be hardened through the addition of carbon, making it ‘martensitic’. However, the most common stainless steels are ‘austenitic’ – these have a higher chromium content and nickel is also added. It is the nickel which modifies the physical structure of the steel and makes it theoretically non-magnetic.

304 stainless steel contains chromium (min. 18%), and nickel (min. 8%). It is an austenite steel and is only slightly responsive to magnetic fields. It also contains 18 – 20% chromium and 8-10.50% nickel, and lesser quantities of some other elements. It is relatively easy to machine and less expensive than 316.

316 stainless steel is a molybdenum-alloyed steel. The fact that it is also negligibly responsive to magnetic fields means that it can be used in applications where a non-magnetic metal is required. It also contains a number of other elements in varying concentrations. 316 can work harden and make machining difficult. It has a much better corosion resistance and is used for marine fittings.

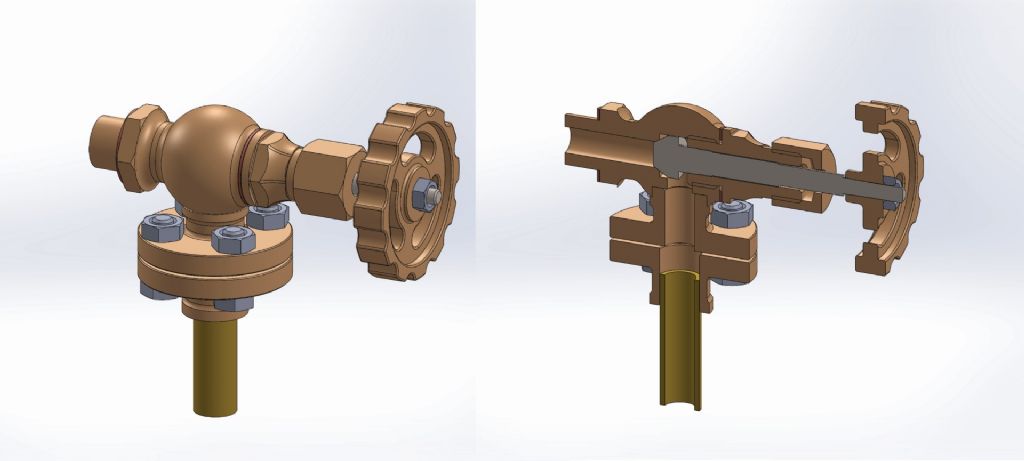

I recently inspected the spindles on some model globe valves which I made about 18 months ago out of 304 S/S because they were not sealing properly and found that the seats were pitted and coroded. Now have to make them again, this time out of 316 grade.

Paul

Bob Wild.