Yes it seems many model engineers are happy doing things the way they have always done and are not interested in new technology . Unfortunately they don't look at things like 3d printing as being of any use to them which is unfortunate as i feel it is always better to add another string to one bow !

I know of a few youtube creators that are using 3d printing for prototyping model engines and making patterns for casting work – all done quicker and probably more accurate than they could make them the old way .

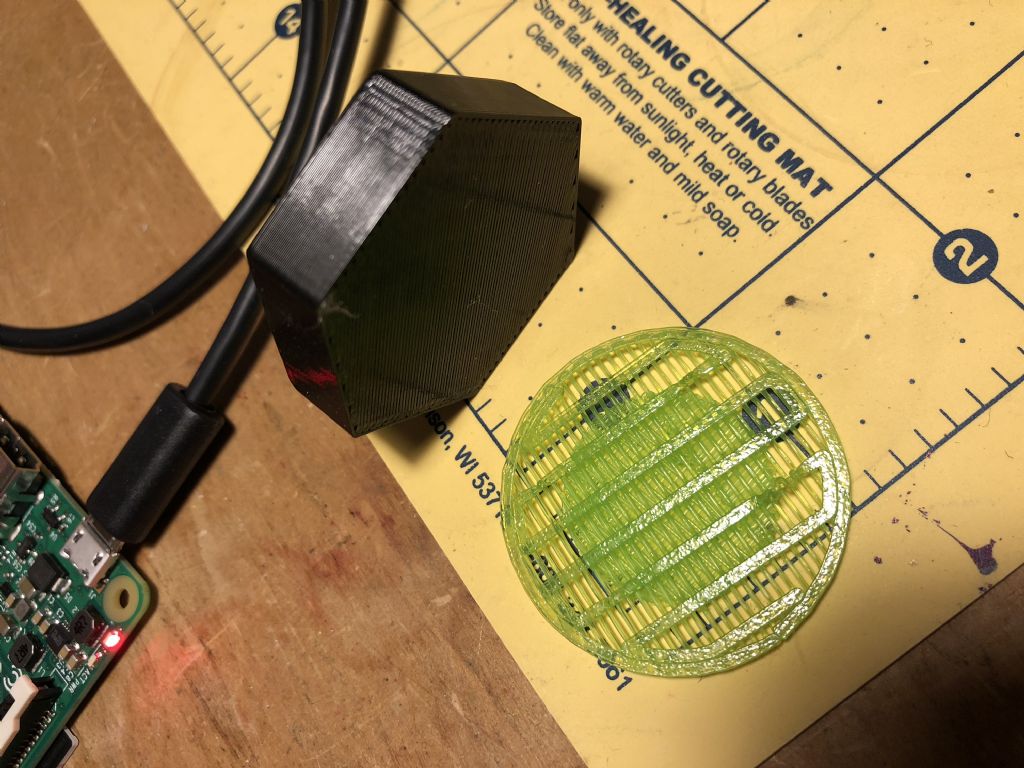

I have now fitted some knurled thumbwheels to the hotbed for ease of levelling and it is so much easier than using an allen key ! Glass bed also fitted and now experimenting with various bonding agents to see what works best for ABS . I have also made up a bracket that clamps to the extruder stepper motor that allows a dti to be mounted for bed levelling and to square up the X and Y axis using a custom made square that clamps to the hotbed . I also made up some small angle brackets to ensure the main frame is at 90 deg to the X&y axis so the z axis isn't doing the leaning tower of pizza sort of thing .

I am also thinking of replacing the dodgy Z axis homing stop screw with a micrometer assembly along with a bearing assembly at the top of the z axis feed screws to take the bounce out of the z axis . Luckily i don't have the wobble problem i have seen on youtube – i think they tightened the locating grub screw before tightening the clamp screws on the flex coupling , i tightened the clamp screws first then nipped up the locating grub screw last and only very lightly at that . Alloy extruder unit also fitted – much better grip on the filament and the plastic one seemed to stick a bit so getting a uniform pressure on the filament was difficult .

Ian.

Neil Wyatt.

Neil Wyatt.