I always set my Z height to zero based on having light scratching against a sheet of paper between the print head and the heated bed and have lovely smooth faces on the finished product once removed (usually the best surface of the finished print!).

I can usually tell whether or not the bed is properly level and extruding properly whilst the initial layer is being printed – I cancel the print if it is too squashed or not squashed enough before the initial layer is even finished and adjust as appropriate – better bed levelling (remember to do this with the bed hot, it changes shape with the heat), or better zero Z height adjustment.

I print onto kapton tape that has been cleaned with acetone, on a glass sheet clamped on top of my heated bed with mini bulldog clips. I change the tape when it starts to look tatty, which if you are careful with removing your prints can be 6 months or more.

If you have left the heat on for the extruder, it is always worth extruding a bit before starting a print, as the plastic in the internal reservoir slowly oozes out and is not replaced if the stepper is not turning – also worth printing an outline to ensure that all is extruding properly before the main print starts.

A date appropriate print of some skeletons I printed last year – the bed was not as level as it might have been and the one on the right had fused joints.

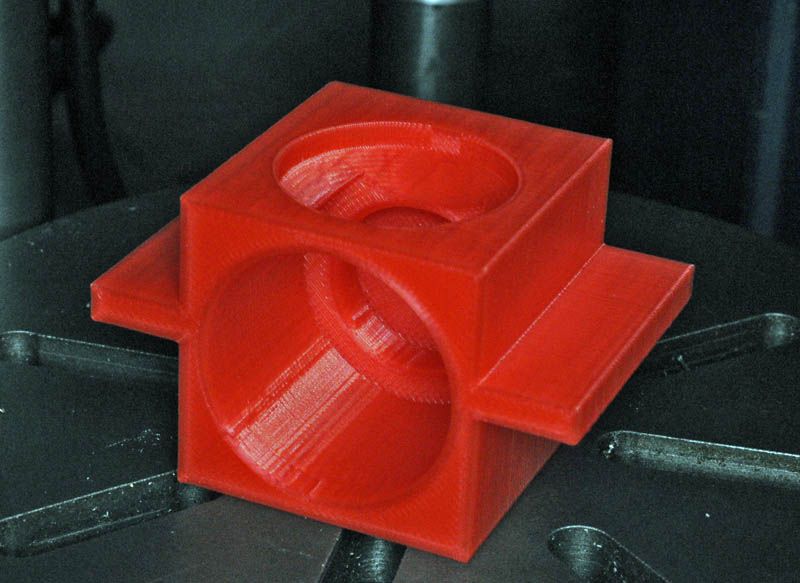

If you look closely, you can see that the perimeter is wider in the lower right than elsewhere on the print – squashed more due to insufficient Z height.

Printed using glow-in-the-dark filament.

Edited By Zebethyal on 31/10/2017 11:28:42

Neil Wyatt.

Neil Wyatt.