Posted by choochoo_baloo on 06/04/2020 23:41:17:

…

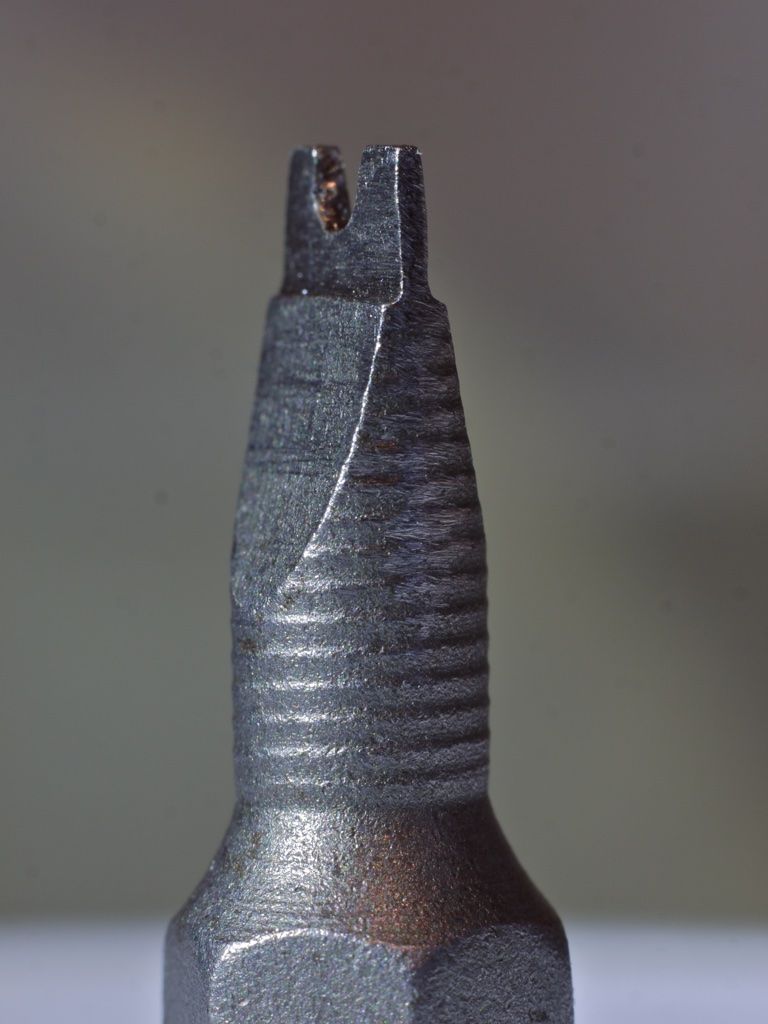

Whilst restoring a Stanley plane and similar aged tools I've noticed an annoying tendency of not quite getting a perfect fit flat head screw driver…

was there an Imperial flathead dimension system that I've missed? …

There are standards but they don't help much. The answer is the width of the slot depends on the diameter of the screw and the thread system.

BA slots are specified in BS57-1920 as being 0.2D + 0.1mm, where D is the full diameter of the thread.

For BSF and Whitworth, slot widths are listed in a table. 8 different slot widths are listed for the 12 screw diameters between 1/8" and 1".

For extra confusion, the depth of the slot is related to it's width and possibly also to the type of head. For example, BA slot depths vary depending on whether the head is Countersunk, Instrument, Round, Cheese, Filister Capstan or Connection.

Metric and other standards follow similar rules.

In theory a different sized screwdriver is needed for almost every type and size of slot-head screw; i.e. dozens of them.

In practice, if the correct sized screwdriver isn't in the toolbox, one can either be ground to fit or the job can be bodged by attacking the screw with whatever is handy. Judging by the number of old machine screws with chewed slots, most of the work in the good old days was done by lazy apprentices rather than master-craftsmen!

Dave

Mick B1.