I've been working on building a digitizer to scan parts, unfortunately, the touch probe I have isn't suitable (I'm measuring very delicate and expensive parts and my probe require a little bit too much force, I'm afraid to use it!)

I've ordered a new one from the far east that operates on the 6 balls+3 shafts principal. It'll not be here before I go away next week, and I want to take my digitised parts with me to work on!

So…. the evening before yesterday I decided to design and 3D print a simple Z axis touch probe using materials available in my scrap bin, mainly, a single microswitch….. and nothing else really useful.

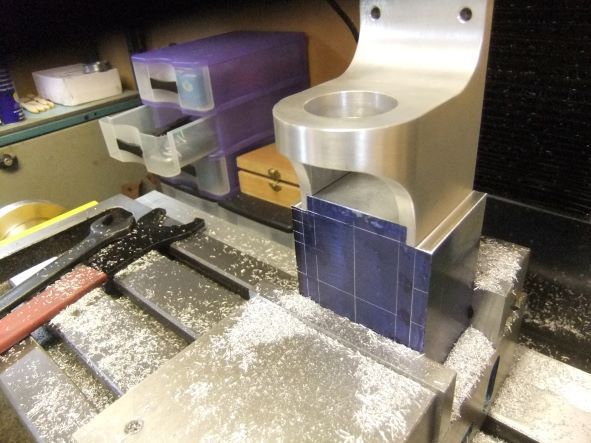

We're on version 3 now, I'll set it off printing first thing in the morning. The first version printed yesterday was more traditional, featured a plunger that rode up and switched the switch, spring return and while it worked, I wasn't happy with the internal friction, even after cleaning up the bore with a drill. A total rethink was called for, why did I think inside the box to start with!?

V2 started printing this morning while I was at work… but my printer died half way thought, so I took the opportunity to tweak the design a bit.

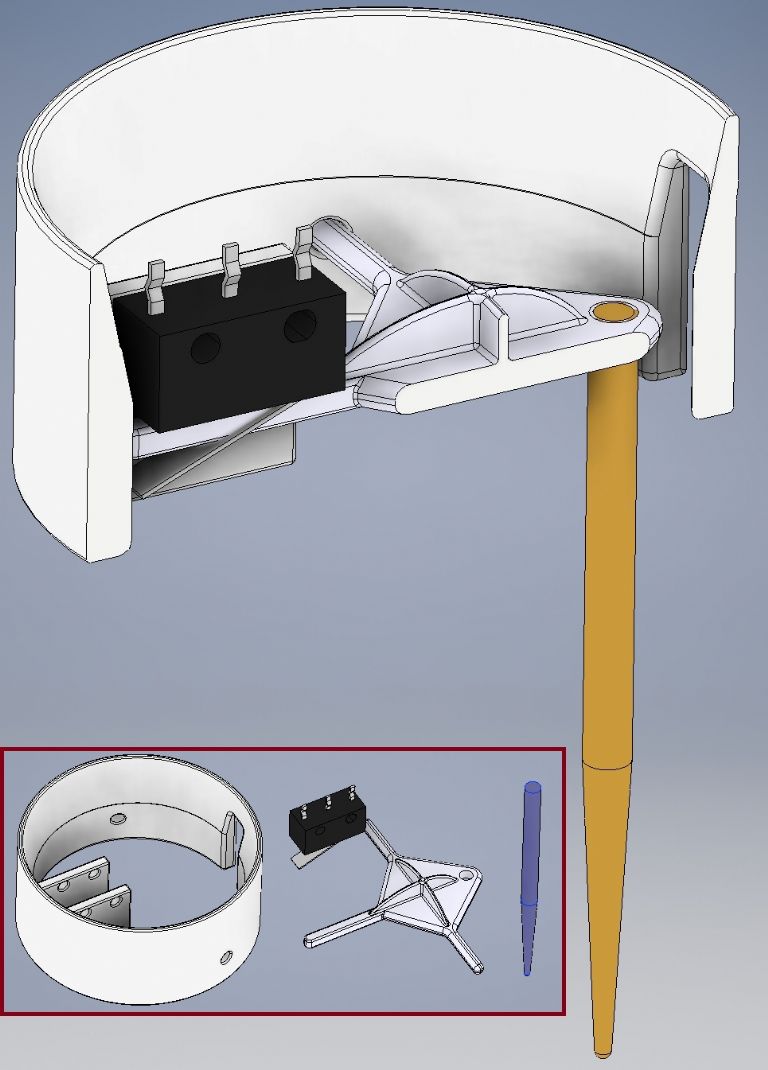

V3 will commence tomorrow morning as shown below. The outer diameter is the same as the spindle in my Sainsmart 3018 cnc router, so motor out, this assembly in. The inner cross carries the brass needle which acts as a weight (more weight may be needed but it doesn't take much to switch). This inner cross pivots in a bore through the outer with a slight clearance, once in the spindle bracket, it can't slide out either side. As the machine moves down, it trips the switch, breaks the NC probe circuit and the the software records the XYZ at that location.

Obviously it just measures Z, the probe I've ordered will sense in any direction and is much more precise. It can be used for edge finding, not just scanning a height map.

Edited By Russ B on 05/04/2023 21:07:17

Matt T.