“401 through 410” it says there. Could do with British-isms not Americanisms!

Catching up a bit over the interegnum….

Two days at the Midlands Model Engineering Exhibition: Thursday as a visitor crossing our suppliers’ palms with plastic; Saturday as a steward on the MSRVS stand.

As in the past I camped on a small site just outside Harbury. The village is only about 3 miles from the venue, easy to reach from the Fosse Way or Leamington – Southam road; and well supplied with shops and pubs.

On the Friday, having done a little prior research, I took the bus to Royal Leamington Spa to enjoy the riverside gardens in tee-shirt weather.

……….

Arrived home to a bank statement with some very odd looking payees indeed. Worried, I did some detective work.

The biggest transfer, <£100, was to a Tipton manufacturer of fancy door knobs and knockers: it transpired they own College Engineering Supplies from whom I had bought materials for collecting at the show. While all those payments to something vague in Crewe were really through ‘Central’ franchise shops; and £20 to a local dancing school called ‘Platinum’ was really for petrol from a local Esso garage using a payment system also called “Platinum”!

Why don’t the documents show points of sale as well as the accounts-addresses?

……..

Having bought all that cast-iron for my wagon’s cylinders, the last thing I want is to mess it up, so I need design it fully and carefully. Experimenting with how to draw it, gave me an unexpected bonus in CAD, that of using two separate makes to dodge round obstacles too difficult in either make alone.

So Alibre Atom to create the basic model: full cuboid outline, the HP and LP bores, cylinder-cover stud holes, ports; but not passages and other internal details. One of Luker’s locomotive drawings showed how to avoid some horrible mistakes in my first attempt.

Then I turned that into five elevations translated in .dwg form to TurboCAD’s orthographic-only mode, to add the details too hard in Alibre but fairly easy in TurboCAD’s 2D-only mode. I need full elevation drawings for workshop use anyway.

Similarly the GA for the engine and transmission can only be an orthographic TurboCAD drawing.

The two systems are near-opposites. Alibre Atom is moderately easy for single, simple, especially symmetrical 3D Part models from which to derive dimensioned elevations; but seems to have no full orthographic option from scratch. Whereas TurboCAD offers both full 2D and 3D options; its 2D mode is fairly easy for me now, its 3D model mode is impossible.

Forming Assemblies in Atom is difficult though importing Parts from their own models is easy. I’ve no idea how to import and assemble them in TC.

So common file formats between them are useful to me. I may have to investigate transferring the finished TC drawing back to Alibre for printing though. TC’s printing system is utterly baffling!

I may then make a dummy version of the cylinder block in wood and plastic to ensure I don’t have holes in the wrong places, etc.

……

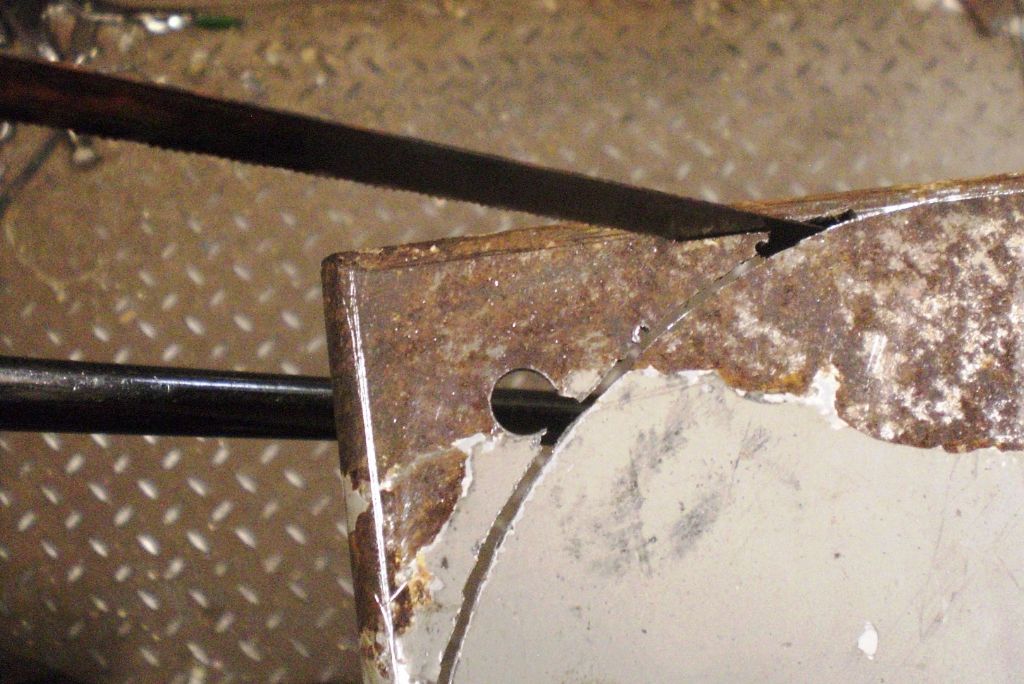

Finally, I succeeded in wrecking my HP A3-size inkjet printer, bought for CAD drawings.

Long periods of disuse had clogged the plumbing but an on-line video suggested it is easy to remove the cartridge and nozzle assembly to flush it. It’s surprising just how much ink it holds! Unfortunately mine was a slightly different version from the machine shown, and re-assembled, it went totally haywire. I’ve obviously done something wrong or broken some hidden detail; but have no idea what.

It was a gamble, because if not restorable, it would be scrap due only to dried ink. Printer repairers are as rare as poultry dentists, except to commercial companies with many printers. Curry’s, from whom I’d bought the thing, don’t repair anything but did give me the details of a local repairer!

So I am taking it there tomorrow to see….. If it’s not feasible then unfortunately it’s off to the Council skip-yard, despite barely five hours’ use in its life.

Matt T.