Posted by Nigel Graham 2 on 04/06/2023 00:06:30:

Jelly –

I am intrigued. What is it?

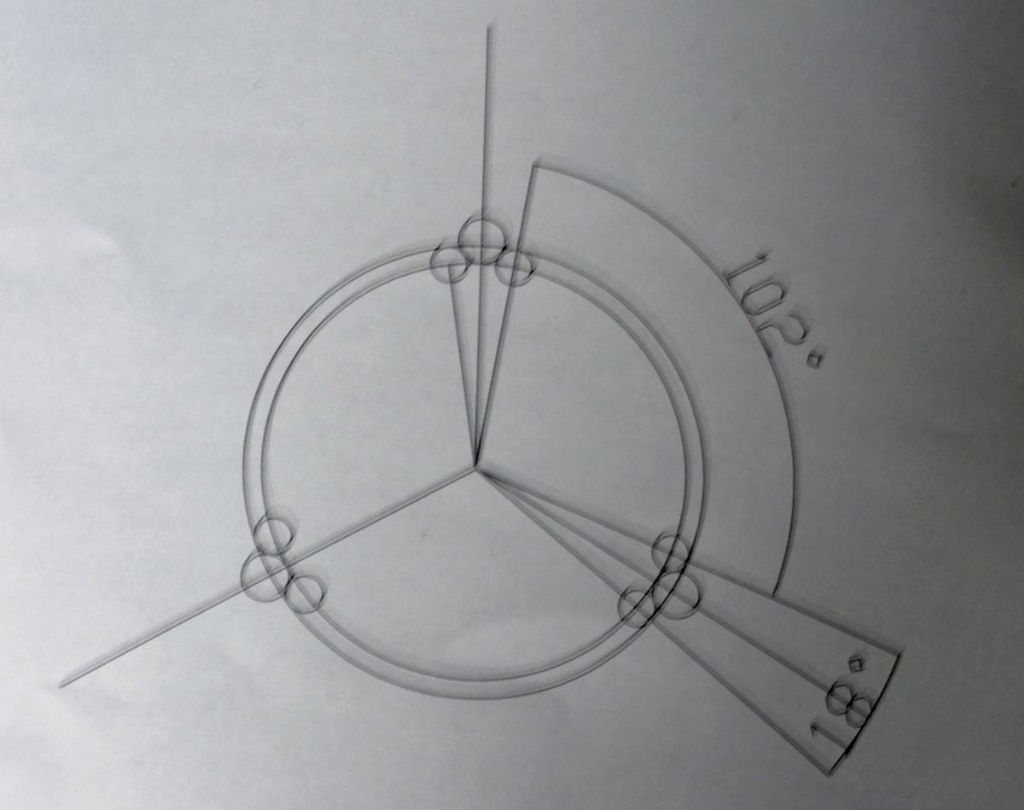

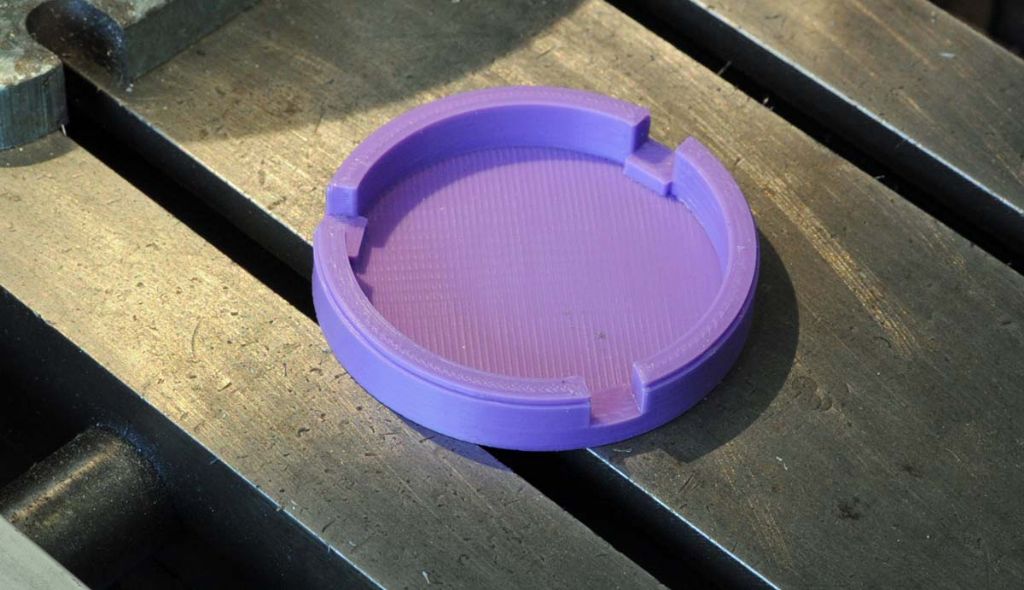

A filing jig for jewellery work (I seem to be beset by jewlers).

There's a 45° and 90° jaw, the tongues are to align rectilinear wire, and the v notches hold hex, D and round wire, along with tubes.

The jaws are hardened so a file skates off them, so you can work right down to it without damaging it (although ideally will avoid doing so deliberately to preserve the file).

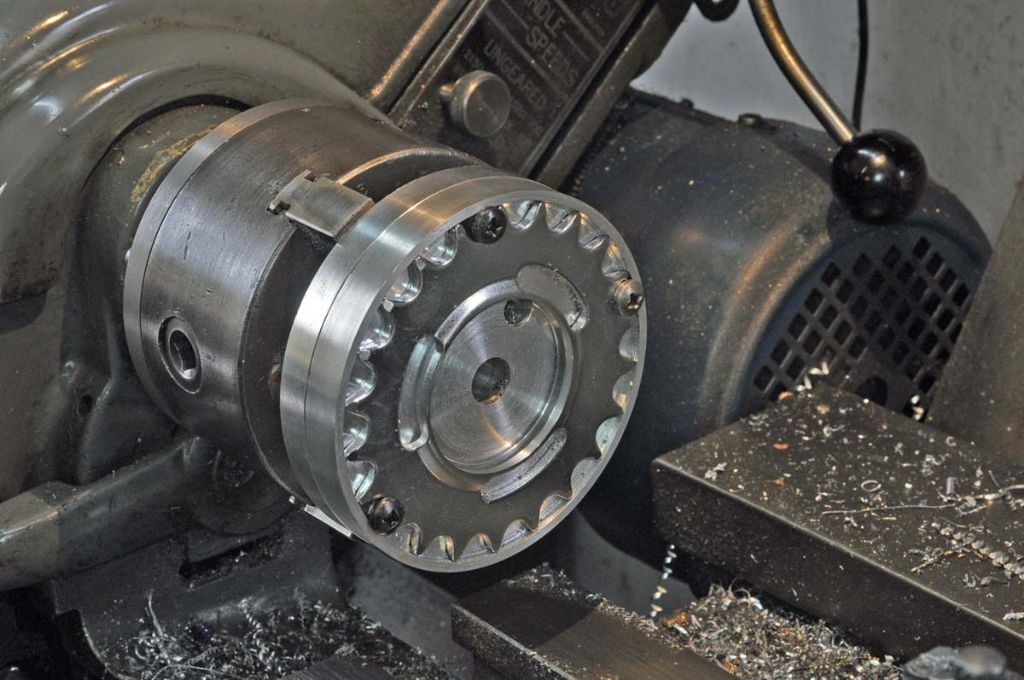

Got a tiny bit more done on it Friday evening:

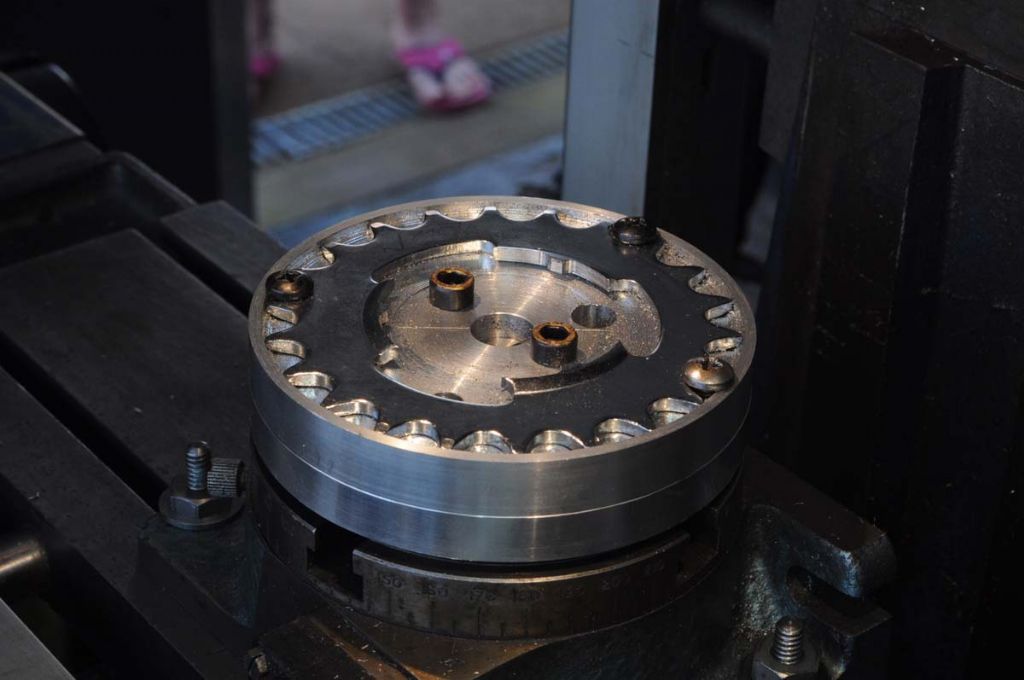

If you look closely at the left hand side you can see where I slipped with the file whilst deburring the edges, which is aesthetically rather upsetting, but otherwise the fit is exactly as desired with about 0.01mm clearance between the tongue and the corresponding slot.

If you look closely at the angled face above you will see that I cocked up my measurements when band-sawing the blank apart, so the 6mm reamed hole doesn't quite reach through that part, which I will need to fix before I'm done.

Also got started with the 45° faces, using an angle block for setup and generous helpings of force to secure it, followed by lighter cuts than normal.

Set up like that I could only take about a 0.75mm DOC, whereas with the 90° face I was able to take a 5mm DOC roughing pass, with 1mm to clean up, all done with a 10mm Carbide 4-flute End-mill running @ 1440rpm (45m/min surface speed).

The 6mm slot was done in a 3 passes with 2mm DOC and a 6mm HSS-CO endmill @ 800 rpm (15m/min), and came out around 0.05mm oversized (which I had already tested and was accounting for to help give me the 0.01mm clearance for the fit). I am going to have to be *much* more gentle making its angled counterpart.

Either way, very happy with the mill's performance… Great MRR in a tough material with acceptable surface finish (what you can see, can't actually be felt, so should lap out quickly once the parts are hardened), ideal for my impatient temperament!

Saturday was fully committed to gardening, finally getting the roses I've been growing from cuttings taken from my late grandparents collection when we sold the house planted in the bed outside my kitchen window, and taking out a few overgrown shrubs in preparation for felling some small trees.

The previous owners of my house didn't really care for the rather narrow garden which had been (somewhat inadvisably) planted with a vast number of vigorous shrubs and trees. After 3 years trying to take a conservative approach, the conclusion unfortunately most of them are now irretrievably oversized for the available space and need to come out, which will leave two adolescent cherry trees, a mature birch, and a "Strawberry Fruit Tree".

Sunday was a walk round Spurn Head with a mate, the birds weren't particularly active, but the hairy caterpillars were in full swing, and we made up for the lack of bird activity by sitting at the point in glorious sunshine as high tide came in for a spot of ship-watching, marvelling at the Humber Pilots hopping back and forth between vessels whilst I tried to predict which Port the various vessels were destined for based on the cargo and if the Pilots guided them from their boat or actually boarded, whilst my mate looked them up online to judge how well I was doing (I did pretty well, but have also had a reasonable history of working with the various ports on the Humber, Trent and Ouse).

I also impulse-bought a chainsaw from a farmer whilst driving over to Spurn, because he had a sign up at the gate, and when I enquired the price was right. It's Sachs-Dolmar in great condition and running nicely, but for the need of a new chain…

Which will help with future gardening plans, but is mostly wanted for milling some big birch logs I've had seasoning for the last 4 years, it's over a decade since I last used an "Alaskan mill", so I might need to get one of my forester or arborist pals to give me a refresher before I jump straight in with that…

Even assuming my chainsaw trousers still fit, I have no desire to test their effectiveness!

Edited By Jelly on 05/06/2023 11:46:32

Matt T.