The cumulation of several Days What I Did Things on…

Photo 1:

Left: Dial Gauge Holder, Top-slide, Myford ML7 and Harrison L5.

Machined from an off-cut of some sort of engineering plastic (probably reinforced Nylon), it temporarily replaces the QCTP block. It places the gauge probe horizontally on the centre-height, used one way up on the Myford and the other way up on the Harrison.

The appropriate hole fits loosely round the tool-post stud on its lathe. On the Myford, the shorter web is downwards and registers against the top-slide end.The Gauge is held by its mounting-lug screwed to the side by the appropriate of 5 tapped holes, and steadied by its body resting on the plastic.

I machine the bulk on the manual Drummond shaper.:

Right: One of the Reels, Cave-radio Ariel-Wire; made for Mendip Cave Rescue. Size approx. 180 X 95 mm outside. I greased the stainless-steel screws and the countersinks with "Vaseline" to give some protection from corrosion, bearing in mind that in use one pair of reels could be lying in a wet pasture and the other hauled through a wet cave! MCR wanted 16. I made "production spares" and ended up with 18 complete reels!

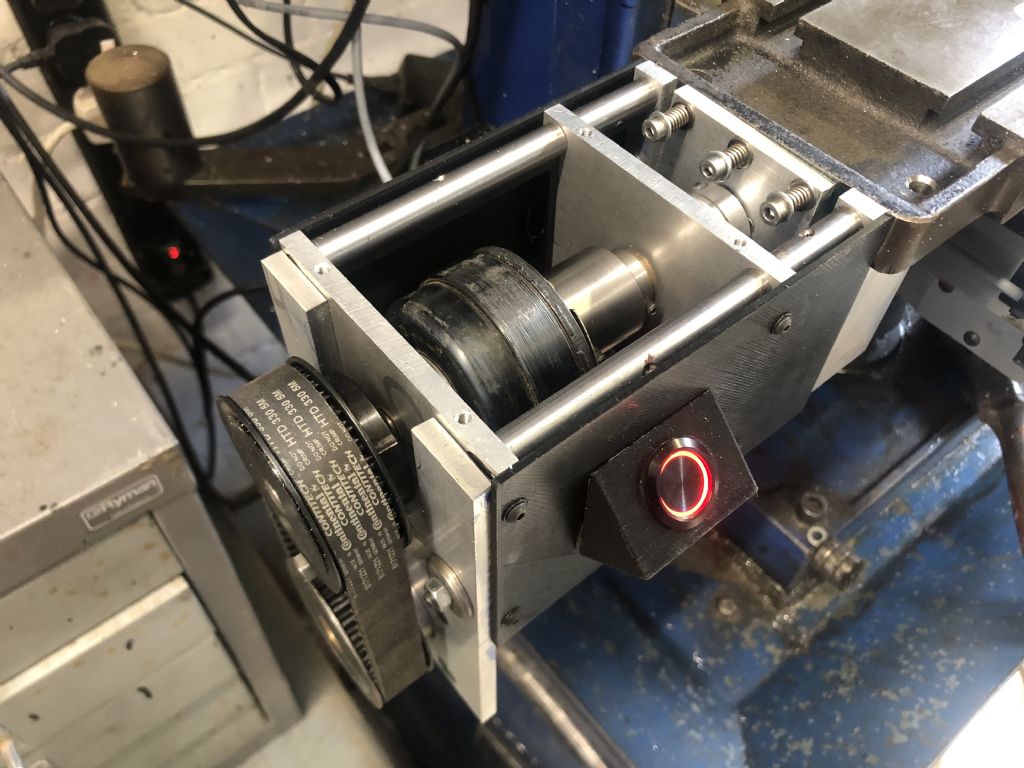

Photo 2: Part of the batch-production line: using the tapping-head for the Ariel Reels' cross-bars. I spotted the tapping-holes on the lathe but drilled them to depth on the bench-drill. The 3-jaw chuck is on a Myford nose-piece registered and screwed into a plate with central spigot, made to be concentric with the BCA Jig-borer table.

(When I make a jig or fixture I try to consider future possible uses.)

Matt T.