What Did you do Today 2022

What Did you do Today 2022

Home › Forums › The Tea Room › What Did you do Today 2022

- This topic has 546 replies, 117 voices, and was last updated 1 January 2023 at 07:02 by

JasonB.

JasonB.

-

AuthorPosts

-

23 December 2022 at 14:51 #625928

Nigel Graham 2

Participant@nigelgraham2Lee –

(Oh, you can use my first name on here!)

The electricals dealer suggested I make a guard from an empty ice-cream tub! A plant-pot with the bottom cut out might be better, and it probably would not matter if plastic, it it is reasonably large. A piece cut from heating boiler flue tube would be effective.

.

I met a complete mental block with SE. I had thought it might be easier to learn than IMSI's TurboCAD, and certainly with more advice available beyond Siemens' own painting-by-numbers tutorials on its confusing web-site. Those seem conversion exercises for people already familiar with earlier SolidEdge / SolidWorks editions.

They don't help you understand it, hence the air of drawing-by-numbers. TurboCAD comes with no tutorial material at all, although its retailer, Paul 'The Cad' Tracy, has written ones for it. TC's on-line "Help" manual is frankly dreadful: minimal explanations, bad layout and no index.

TurboCAD's 3D mode is far harder than SE in one respect. It contains a hidden trap giving effects impossible to correct. SE seems not to have this trap.

'

I'd basically tried re-learning CAD from the start, because the two makes differ so much. That showed suddenly I need learn and understand a vast store of knowledge before producing any useful drawing of even the simplest, single component.

Basic manual orthographic draughting is fairly easy to learn or revise, and is transferable. Ignoring any latest ISO-rhubarb, a drawing text-book from 1938 is as valid as one from 1978; especially for a model of something introduced in 1908. What matters is a clear, unambiguous and accurate drawing.

The primary drawback of manual drawing is that copying a part or sub-assembly across a GA or from sheet to sheet, needs you draw it all individually. Easy but slow manually, rapid but very difficult digitally.

'

Not just CAD. Similarly, a foreign language, advanced mathematics or a musical instrument needs memorising and understanding a huge volume of knowledge, to use any of these even at basic level. If so swamped by seeing how much, that the brain closes in self-defence, you have no hope.

I think too, we all have both an innate ability for particular classes of work, and an innate, finite "volume" for it to occupy. The brain is not like a computer RAM at all; but though I have no idea if it imposes a physiological cell-count limit, it still limits the subject's volume or level.

Where I go from here? Probably, TurboCAD in 2D mode only, ignore its 3D mode; but do I even need make proper drawings at all? My "life-long" project has no drawings and progress is painfully slow due partly to so many changes and re-makes necessitated by unforeseeable problems I have created, perfectly unwittingly, sometimes years previously. Making pretty isometric pictures on a computer won't solve that problem; but I cannot make such pictures anyway.

'

That is a lovely project, your model Austin Sevens.

My approach to the initial drawings for something like that might be a set of orthographic-view photographs I can print at reasonable size (limited by the A4 printer and print definition), then trace.

I have used this to a point with my steam-wagon. Although I have not used it extensively, I discovered I can import photos of the work so far into TurboCAD, and dimension them. This does not give absolute dimensions of the photographed metal, but dimensions the photo itself sufficiently to guide the proportions and arrangements of the next stages. I can also measure the work itself for scale and accuracy; then edit the image's dimension values to match the real thing without changing the image.

(In SE's dimension tool, altering the number actively alters the drawing. Useful, if you know how to avoid some peculiar results; but not for dimensioning a photograph – if that's even possible.)

23 December 2022 at 15:16 #625930lee webster

Participant@leewebster72680Nigel,

If it wasn't for 3D cad, I wouldn't have got anywhere with metal casting, 3D printed patterns, or making my model A7s. If I had tried making any parts from solid material, wood, clay etc. I would have fallen on my face long ago. Without knowing what you have been trying with SE I wonder if you might be better off working on the design of a part you are familiar with instead of trying to follow a tutorial. I admit that the user interface in SE is a bit meandering, but it does seem that all the commands to do things are there, somewhere! I watched a video this morning about wrapping text around a curved surface, in my case that could come in handy.

I bought the flower pots I used from B&Q, I didn't cut the top off though. Any heat generated by the light will escape through the pot's drain hole. I also bought a size big enough not to need extra matrial removed for the lugs on the lights, just the cable.

Lee

23 December 2022 at 16:37 #625938Nick Wheeler

Participant@nickwheelerPosted by Nigel Graham 2 on 23/12/2022 14:51:08:'

I'd basically tried re-learning CAD from the start, because the two makes differ so much. That showed suddenly I need learn and understand a vast store of knowledge before producing any useful drawing of even the simplest, single component.

'

Not just CAD. Similarly, a foreign language, advanced mathematics or a musical instrument needs memorising and understanding a huge volume of knowledge, to use any of these even at basic level. If so swamped by seeing how much, that the brain closes in self-defence, you have no hope.

Where I go from here? Probably, TurboCAD in 2D mode only, ignore its 3D mode; but do I even need make proper drawings at all? My "life-long" project has no drawings and progress is painfully slow due partly to so many changes and re-makes necessitated by unforeseeable problems I have created, perfectly unwittingly, sometimes years previously. Making pretty isometric pictures on a computer won't solve that problem; but I cannot make such pictures anyway.

Nigel, you have a very strange idea of how complicated things are taught and especially learnt! Nobody is taught to play The Way it Is on the piano, ring Yorkshire Surprise Maximus, drive round the block or read War&Peace in Russian by learning the theory of how piano strings vibrate, do the physical calculations of rotating bells and how they're tuned to make all five notes compatible, disect an F1 lap or do an MA in Russian grammar.

Instead, a teacher will show their students a couple of basic steps and build on them in a structured way using repeated exercises, explaining the more advanced concepts once the student learns enough to make sense of them. This tends to fall apart when students try and force concepts they don't understand into unrelated things they already know.

Which is what you've been doing with 3D CAD – many of the 'easily learnt' orthographic techniques( they certainly weren't easy for me and my classmates 38 years ago) are irrelevant and indeed confusing. Your 'pretty isometric pictures' comment proves that. Chopping and changing the program you're using won't help, as they all use the same basic concepts.

Do yourself a favour, and either delete the programs or get a couple of hours of face-to-face tuition explaining how to model a simple assembly that you already understand; like the injector you've previously mentioned.

23 December 2022 at 17:17 #625942Nigel Graham 2

Participant@nigelgraham2Lee –

Thank-you for the flower-pot tip.

The first two lamps are actually pendant fittings but I still don't want to bury the cables under the matting, if I can help it.

Since the surface is plaster-and-lath, some pieces of broken slate on the higher lumps will probably raise the pot enough for the cables to follow the "valleys". I don't yet know what I will find in the other half of the loft, above the main bedroom, but I have already replaced the inset halogen GU10 lamps there with l.e.d equivalents.

…

I was never intending to try 3D printing. I can't afford it, but anyway it would be far beyond me!

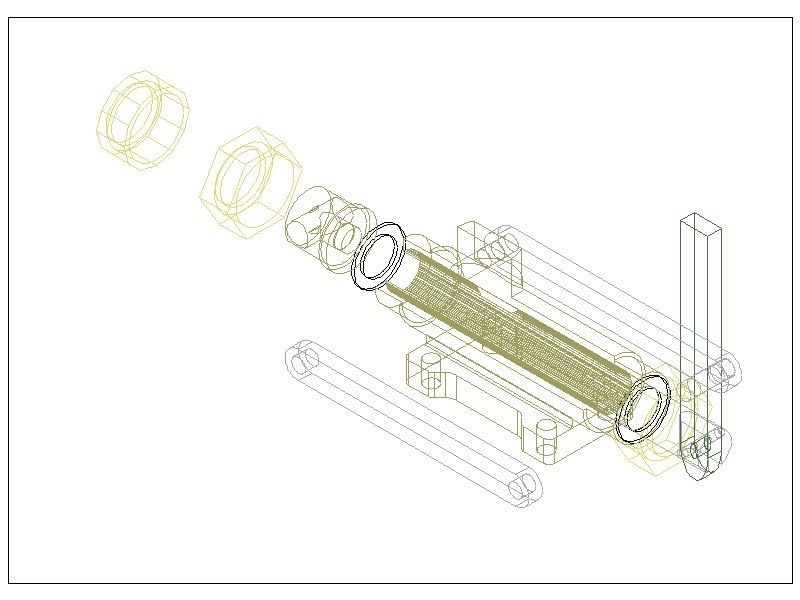

I take your point about using a known part though; and I have done that with TurboCAD as an exercise; as shown below: a sectioned hand-pump and the outline of the steam-wagon nearly so far. I omitted the springs and Ackermann steering as too hard to draw.

Neither drawing has any practical use. I cannot take dimensioned elevations from them; and TC's printing method is an absolute nightmare. Matching scale, paper size, printer size, image and annotations like dimensions, to produce a fully-readable print of actual or chosen scale size is harder than knitting fog.)

What is strange though, is that I had rendered the pump drawing, but translating it from its .tcw drawing-file to a .jpg , turned it into wireframe format, I have no idea why.

The pump is a real item, so far just the casting, but I intend it as a hand-pump for the steam-wagon. The end-fittings are standard plumbing union-nuts to hold a gland at one end and valve manifold at the other.

The bore wall shows one aspect of TurboCAD: its two, at least, internal ways to generate a "solid". Extruding a base circle creates a polygonal prism, hence the parallel lines. This is the trap. The different internal routines produce results with different reactions to the same editing tools, including shattering the entity into lots of individual, rectangular facets. Unfortunately you cannot determine this in advance; nor correct it.

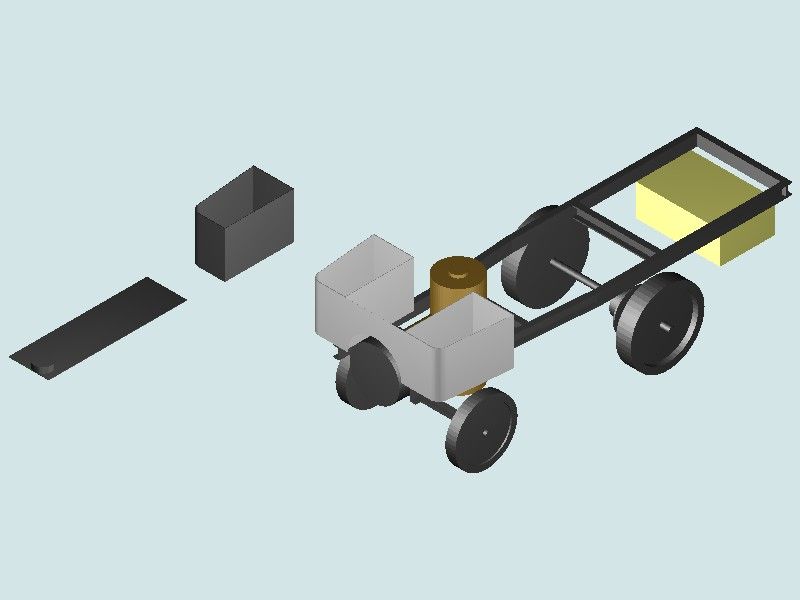

The bits floating past the wagon are individual bunker and bunker floor, from which to chivvy copies into the right places on the chassis. It is all very simplified and rather stylised: e.g. I cannot draw the wheels' pairs of dished, flanged, rose-pattern pierced plates. Similarly I had to represent the differential with its external chain-sprocket as just two cylinders, partly hidden by the nearside wheel.

(The original differential was more like that on a traction-engine, on the back of the wheel, but I did not discover that until years after making the correct traction-engine type, cannon-shaft axle but giving it Foden Overtype style, an inboard differential; modified from a front-wheel-drive car unit. That chassis, wheels and axle are all nearly twenty years old now, and, rivet-spotters please note, they can ruddy well stay like it! The next problem is making the engine and transmission, below and between the crew seats also omitted from this GA, so they line up).

23 December 2022 at 17:33 #625947Nick Wheeler

Participant@nickwheelerAckerman steering is ridiculously easy to draw in CAD as it's just a line that starts at one point, goes through another(the kingpin and steering joint or vice-versa depending on whether the steering is behind or in front of the axle) and ends at the centre of the rear axle. You don't need to know where these are, but use them to constrain the line. If you can't go through all three points, you don't have Ackerman geometry. What's most useful is that you can use the kingpin and axle points to create a line for your steering joint to fall on, with no measuring, calculating or design required. in a 3D model using the other suspension axes in the same way will allow you to demonstrate and measure and correct the actual bumpsteer by having the computer animate the joints. The mockup hotrod chassis I've shown elsewhere has far too much camber gain in the rear suspension to be workable…

23 December 2022 at 19:02 #625960Nigel Graham 2

Participant@nigelgraham2Nicholas –

I do appreciate the difference between trying to teach yourself and being taught by someone who – vitally – actually can teach.

(There are plenty who are skilled but hopeless at imparting their skills: like my school Maths teacher who was interested only in the bright ones who found it easy, and treated anyone else as idiots.)

Obviously I would not expect a beginner only just knowing a crochet from a quaver to play something by Rachmaninov, any more than I'd expect going from drawing a block on a screen, to embarking on a 3D GA of a 4"-scale Fowler road-locomotive.

I think it raises the much broader question of how we learn anything academic – taught or self-taught – and at a biological level, too.

'

I still hold that we have a finite capacity for any given subject. However we learn won't affect that, but will affect how much we learn within that capacity.

The difference between teaching yourself and being taught, is not just opportunity and affordability of tuition.

A proper teacher would largely shield you from the Rachmaninov or the Fowler, but might use them to inspire you. If trying to teach yourself you see only those mountains, hiding the foothills, so are likely only to be baffled, upset and deterred.

That may be what happened to me. SE led me so far up the path then abandoned me where it became a confusing maze. TC never even had a path, although its agent sold an introductory .pdf "book" on a CD, with the main disc..

The CAD publishers' main customers are companies employing professional design departments of fully-trained staff, so they promote what it, not its user, can do. Which is all very daunting. Also, they expect beginners to be employees or university students being trained professionally. Amateurs unable to use such training, can sink or swim alone.

.

I tried SE genuinely thinking it would be simpler than TurboCAD, and in some ways it is, as far as I could progress with it. Not far.

Yet the drawings above are in TurboCAD, at my limit but further than I could progress with SolidEdge. I know they are rubbish, of no engineering use, but at least they are of assemblies, not single pieces.

'

Therefore, I had hit my "volume" limit with TurboCAD, so although SolidEdge does the same thing with very different controls, and although orthographic and isometric CAD are totally different even within the same programme, I was still trying to stuff more CAD into a "CAD store" already full.

Ditto with advanced mathematics or French. I always found them hard; reached my limits years ago, and cannot take them further. It is not the subjects that are the problem but ability to learn them, and to what extent.

.

I have heard that, no, we don't have a theoretical maximum to any chosen skill; but I am not convinced. Well, obviously, there are top-flight concert pianists who can play an entire concerto line from memory; there are also people who can use industrial-grade CAD to the programme's designed limits.

Is their brain capacity all the greater than mine, for those skills? Even with physically much the same volume of "little grey cells" overall; assuming, alarmingly, mine being still healthy?

So, their music or engineering-design capacity is far, far greater than mine, and not "full"; but do they still have physiological (not psychological) limits to their abilities, not met, beyond their needs?

Have their memories sacrificed "room" for other subjects?

I don't know – I am not a neuroscientist and I do not know how learning works in order to remember lots, understand it all, and solve its problems – but it is an interesting biology question.

23 December 2022 at 19:31 #625966Nigel Graham 2

Participant@nigelgraham2Nicholas –

Sorry I missed the previous.

Steering.

Yes, I'd set it out but on the drawing-board, years before knowing about CAD!

I have a book, I forget which, containing the basic geometry.

What I meant about omitting it from that CAD drawing was not designing it but depicting the components already made. Like the springs, they proved too difficult for me to draw and insert into the assembly.

I know it's possible to animate mechanisms in CAD, but not for me! As the Edwardian draughtsmen did, I plotted the limits of movement by drawing them. The important bit is stopping the wheel just clear of the side of the spring; and that can be done on the eventual, permanent steering-gearbox.

The rest on this vehicle is not critical, as the spring movement is miniscule. I don't think the slides on the rear ends only, of the front springs have more than 1/8" travel; and I don't know the vertical range. I have yet to have the springs heat-treated….if I can find anywhere to do that,or a way to do it myself.

I'd omitted the seats too, but I forget why although they are only rectangular wooden boxes. Crew comfort was not a priority in Edwardian times. I think I'd left them off to try to represent the engine. It is an enclosed, inverted-vertical unit which stands up between the seats, with the crankshaft and transmission gears below the chassis, behind the firebox.

.

It is an unusual lorry, and sometimes I almost wish I'd stuck to my original idea of building a Foden 'C'-type overtype… but everyone has one of them!

Edited By Nigel Graham 2 on 23/12/2022 19:42:00

24 December 2022 at 11:07 #626014Dick H

Participant@dickhTried to remove the top drive pulley from the spindle on a Proxxon FF230. There is a tiny grub screw to loosen and then as far as I can see from the exploded diagram it should just pull off but doesn't. I´m very wary of using too much force and a puller is more likely to bend the aluminium pulley stack. I just wanted to tighten the screws that hold the drive to the quill but they are hidden under the pulley.. Any suggestions please.

24 December 2022 at 11:32 #626016 Jim NicParticipant@jimnic

Jim NicParticipant@jimnicHi Dick

I've no knowledge of your machine but sometimes when manufacturers use grub screws in such applications as you have there are in fact 2 screws used. The first one in secures the pulley and then a second is put in on top of the first to lock it in place. May be worth you completely removing the top screw and checking if here is another underneath it. HTH.

JIm

24 December 2022 at 11:49 #626020 John Doe 2Participant@johndoe2Posted by Nigel Graham 2 on 23/12/2022 14:51:08:

John Doe 2Participant@johndoe2Posted by Nigel Graham 2 on 23/12/2022 14:51:08:……..The electricals dealer suggested I make a guard from an empty ice-cream tub! A plant-pot with the bottom cut out might be better, and it probably would not matter if plastic, it it is reasonably large. A piece cut from heating boiler flue tube would be effective……

……..I'd basically tried re-learning CAD from the start, because the two makes differ so much. That showed suddenly I need learn and understand a vast store of knowledge before producing any useful drawing of even the simplest, single component.

Basic manual orthographic draughting is fairly easy to learn or revise, and is transferable. Ignoring any latest ISO-rhubarb, a drawing text-book from 1938 is as valid as one from 1978; especially for a model of something introduced in 1908. What matters is a clear, unambiguous and accurate drawing.

The primary drawback of manual drawing is that copying a part or sub-assembly across a GA or from sheet to sheet, needs you draw it all individually. Easy but slow manually, rapid but very difficult digitally.

'

Not just CAD. Similarly, a foreign language, advanced mathematics or a musical instrument needs memorising and understanding a huge volume of knowledge, to use any of these even at basic level. If so swamped by seeing how much, that the brain closes in self-defence, you have no hope.

I think too, we all have both an innate ability for particular classes of work, and an innate, finite "volume" for it to occupy. The brain is not like a computer RAM at all; but though I have no idea if it imposes a physiological cell-count limit, it still limits the subject's volume or level.

Where I go from here? Probably, TurboCAD in 2D mode only, ignore its 3D mode; but do I even need make proper drawings at all? My "life-long" project has no drawings and progress is painfully slow due partly to so many changes and re-makes necessitated by unforeseeable problems I have created, perfectly unwittingly, sometimes years previously. Making pretty isometric pictures on a computer won't solve that problem; but I cannot make such pictures anyway.

I think it is safer for downlighter covers to be fire proof. If, god forbid, your house caught fire, a plastic cover would quickly melt and allow flames to get through to the floor above much more quickly than if the cover was non flammable and could hold its shape and protection when heated, (and at least partially seal the gap). A plastic cover or tube would burn, as well as melting, compounding the problem.

Learning CAD is a similar process to learning a foreign language, but the brain's language learning centre shuts down at quite an early age. Young children can learn multiple languages (and computers) easily, if exposed to them, but adults find it much harder. CAD presents the same problems as learning a new language, so it's not us being dim, it just takes more effort.

Regarding manually drawing; it depends why you want the drawing. If you are designing something new, it is helpful to be able to view the project from any angle, and "look inside it" etc, which is very easy to do with CAD and a mouse or a trackpad. Ditto, adding features such as fillets, or moving holes – all achievable in real time with CAD, but very laborious with manual drawing.

The copy and mirror functions for example can be used to create a gear wheel, after defining and dimensioning just one tooth, and clicking the mouse to copy that around the whole circumference – having defined how many degrees separation between teeth that you want. Being able to change dimensions and have the rest of the object adjust to that instantly when you click return is also very handy. CAD will create 2D drawings from your 3D object at the click of a mouse, which is massively time saving. Depends, what you need it for.

I remember years ago, my Dad literally painting a simple sign on a piece of wood for a party, which, bless him, looked crude and amateurish. My approach would have been to print the sign e,g, "Happy Birthday", on my computer, which could automatically divide and print it over several sheets of A4, which you then attached together to make the final sign.

I am finding Shapr3D to be quite easy to learn and create relatively simple 3D objects for 3D printing. I haven't tried using it to draw machines yet, with axles and cranks etc., but I have seen a tutorial where a helical gear is easily defined and drawn from scratch in just a couple of minutes. And which can be turned and viewed instantly from any angle just by moving the mouse.

Edited By John Doe 2 on 24/12/2022 12:02:36

24 December 2022 at 12:03 #626022Robert Butler

Participant@robertbutler92161If you have a split bearing puller which you can use to encircle the lower pulley that may spread the load over the entire base of your recalcitrent pulley.

Robert Butler

24 December 2022 at 14:03 #626032IanT

Participant@iantI always struggle to find things as 'Stocking Fillers' at this time of year but saw a 'book-holder' (on Thingiverse) that looked a suitable candidate for someone who likes to read in bed with a cup of tea in one hand.

I couldn't download the STL for some reason and rather than mess around, I just copied the idea in Solid Edge. It was a very quick five minute job to get the basic holder drawn but then another fifteen or so, figuring out how to embed the names (which I'd not done before).

Merry Christmas everyone…

IanT

24 December 2022 at 22:04 #626077Nigel Graham 2

Participant@nigelgraham2John –

Re-reading, I may have misinterpreted the dealer in the matter of ice-cream tubs (the large box types, not individual serving size). More likely he'd told me what other people have used as insulation guards; but I agree, it's not something I'd use!

''''''

I think learning anything becomes harder with age, but it is not a universal rule. Some of my age (70) seem to pick up things very easily, that baffle we lesser mortals.

…

An application idea occurred to me this afternoon, re dimensioning photos imported into a TurboCAD file.

I was discussing with friends, old ariel photographs of a particular area of landscape interest. This is farmland, and many decade, farming and weathering can change or obliterate minor natural features, and certainly artificialities like tracks and field boundaries.

The farmers are careful not to damage natural or historical things that are officially protected, but small pieces of topography, hedges, etc can be lost; and this was much more common in the past than it is now.

So correlating a lost feature's old position with what we see now, is not easy.

I recalled describing above how I'd used TurboCAD to dimension a photograph of my model wagon so far, where the corners are sufficiently distinct. So can I use this technique to correlate copies of old and modern (E.g. Google Earth) landscape images to identify long-lost things?

.How? Triangulation.

Draw on both image copies, base-lines between pairs of data points like farm-houses and road junctions common to both; and from them lines to the features of interest on the old photograph. Then measure the angles between the lines, using the programmes' dimension-tools, and transfer this triangulation to the modern image.

The photographs need not be to the same scale or compass orientation. Well, we'd not expect them to be. The method relies on angles in similar-triangles; and does not need compass-bearings either.

I don't know if this will work, but it is worth a try. I'd have first to find how to draw an angle at some random value. In engineering drawing we usually work in elegant factors of 360 like 15, 30, 45, 60 etcº., all easy to set.

TurboCAD's angle-step presetting menu is ideal for machine and architectural parts. For map work the pre-set increment may need be as fine as 1º. TC does not have an equivalent of SolidEdge's proactive dimension system so I'd need find if an angle can be set by typing it in. The display holds a special value tool-bar it calls its "Inspector Bar", in which you can enter values like circle radii and grid co-ordinates.

The fly in the Trefolex might not be the CAD use at all, but in whether either of the photographs can be copied. They are of course likely to be copyright but, this is for private, non-commercial study. It may mean though that they live behind copy-prevention software. If so I'd could only print them and triangulate theese manually. That might not be much slower than using CAD, and would be simpler, since the number of features would be very low; but it does needs prints at a useful size.

++++

Regarding TurboCAD's tools generally, yes, I have used its various copy tools a lot, including Radial Copy to step things like holes on pitch-circles; and Linear, to set out a row of objects. Also Mirror: I used that a lot to produce that wagon drawing above.

The bunkers had me foxed for a while because they were either solids that could not hold the coal, or had no floors so the coal would fall straight through! Eventually I realised the plan outline needed an invisibly tiny gap in one corner, so it would Extrude as a "wall" not as a block. Then make the floor as an Extruded, fully-closed 'polyline' copy of the outline. I Mirror-copied both then Assembled the copies to the chassis, corner to corner.

That business of fully-closed polylines had me puzzled for a long time when I first tried using TurboCAD. I could not hatch cross-sections and did not understand that although the image looks intact to the eye, the lines must meet to extraordinarily tiny fractions of an inch or mm, precisely pixel-on-pixel. And then, if not a library polyline, be linked as one. And that won't work without using the correct Snap tools.

The old convention for showing gears is simply three concentric circles: Dedendum, Pitch and Addendum, for each; with a note giving the tooth-count and DP or Mod. Sometimes it is necessary to show two or three teeth on each, but really only if you are designing the gears to tooth-level. These have the advantage of a less cluttered drawing.

24 December 2022 at 22:22 #626078lee webster

Participant@leewebster72680I went to a local model making group last night which was the last meeting of the year. I spent the evening preparing the support legs for each of the 4 Austin 7 models I am making, 4 to each car. I printed the legs in pla on my Ender3 and I should have printed them solid rather than hollow. They are 4mm dia and quite fragile. So today I drilled a hole in the top of each leg and made sure there wae a clear path through to the bottom of the leg. I cut some 1.5mm steel wire to length and mixed up some JB weld. The JB weld was fed into the small hole with the help of the wire to get the glue as far down the leg as I could, and the wire was then inserted and the hole filled over. 16 legs later I packed in for the night. I used about 40 to 50mm of JB weld, so I am fairly sure it got all the way down.

Merry Christmas to one and all.

25 December 2022 at 00:07 #626084 BazyleParticipant@bazyle

BazyleParticipant@bazyleWent to Men's Shed but nobody else turned up – wives collared them for shopping etc.

Chased a sheep round garden trying to persuade it to head for the open moor but it just headed for the field it isn't supposed to be in. Amused then to find that there were two penned sheep at the crib service in church – glad I'm not a warden at this church or I'd be the one cleaning up.

Finally a family zoom call taking in UK, Sucre in Bolivia (yes I'd never heard of it before either) and Melbourne – wow has communication advanced since my childhood when we though airmail letters amazing compared to the two week surface mail boat just as far as West Africa.happy Today everyone.

25 December 2022 at 07:52 #626092 BazyleParticipant@bazyle

BazyleParticipant@bazyleGot a text at 1.30 am to say they had been fiddling with the Hive heating at the other church 250 miles away where I am a warden. They had put it to manual and moved the wireless thermostat to over a radiator so it turned off when it got to 22C. I think it then timed out the boost setting and turned off. Managed to put it back to auto so it would come on properly this morning but now the internet is offline so can't check.

25 December 2022 at 08:12 #626095 JasonBModerator@jasonb

JasonBModerator@jasonbNigel you don't really need angles for triangulation just lengths between various points so you won't need to go looking for angles in your CAD, even if you do want to use angles they and not entered as values but are measured between the previously drawn lines.

I mentioned last week in another CAD related thread that age does not always come into it, this was done by an 85yr old who had only been using Alibre's trial for two weeks, not just a" fancy isometric" but an assembly of all the parts (internal as well) that all move around as they should.

Must go now there is a package from ARC under the tree that needs my attention.

25 December 2022 at 14:47 #626126Nigel Graham 2

Participant@nigelgraham2Thank you Jason.

What I meant by entering the angles, was that having measured one image, doing that would be part of plotting the same readings onto the other.

It can also be done, probably more easily and accurately, by intersecting arcs struck from the corresponding base-line ends, having established the ratio of the two versions by the base line lengths, to calculate the plotting radii.

That is feasible in TurboCAD too, as I have used the basic method to verify a drop-down ash-pan's hinge point. I drew circles on the hinge axis, crossed with diameter lines at the closed and open positions, to ensure the edge of the grate would clear the firebox wall.

Then realised after making most of it, to that drawing, that I was creating a mass of over-complicated steelwork not all prototypical!

+++++

Yet to see what anyone's sent me, ARC or not (probably not). I spent the morning doing a bit of garden work then two or three hours of actual model-engineering in the workshop, in the friendly company of Radio Three! Duty calls though and I'm family-ing later this afternoon.

++

I am impressed by that engine drawing!

My comment about "fancy" was meant to apply only to my efforts – I know it's possible to animate drawings to verify clearances and operation, but that's for the experts.

Happy Christmas!

26 December 2022 at 10:43 #626163SillyOldDuffer

Moderator@sillyolddufferLooks like today will be spent recovering from yesterday's excess! Though booze was minimised, I ate too enthusiastically and unwisely for a man with diverticulitis. Anyone else interested in my exploding bowels?

Dave

26 December 2022 at 11:20 #626173Robin

Participant@robinAlways let your wind go free

Or it will be the death of thee

26 December 2022 at 22:47 #626236

26 December 2022 at 22:47 #626236Nigel Graham 2

Participant@nigelgraham2Dave…

Errr, no beyond wishing you rapid return to normal conditions!

;;;

Me –

Continued making my steam-wagon's ash-pan (V.3). Having started its top plate yesterday, I completed most of the work on it this evening.

The pan consists of two 'D'-shaped plates of 1mm sheet-steel, flanged (ish) over a former carved out of an old car brake-disc, as roof and floor, with a rolled strip yet to be made, as wall. The material was a scrap domestic boiler panel.

Of 7" outer diameter, the roof plate has a 5" dia hole through it to locate round a projection of the inner firebox below the foundation-ring.

Having trepanned that hole, with the blank sandwiched between a steel ring and a piece of plywood screwed to the lathe face-plate, I had the question of cutting the semi-circle of the 'D' . Solved that using the lathe as a sort of shaper: with it already in lowest gear anyway, I isolated the power and rotated the spindle half a turn and back by its motor belts, feeding the cut from the top slide. Slow and laborious, but it worked! A dose of 'Rocol' tapping-fluid greatly eased the operation.

A few minutes hacksawing and filing dealt with the tangential sides; deburr and blunt the edges by file; then clamped the plate to the former to flange the perimeter for the assembly, and the inner hole' s rim inwards for rigidity.

It's a bit grotty and distorted, so needs tidying. Also the flanges still need bringing to a right-angle (I have no half-moon stake, so will have to improvise).

I'm in two minds how to assemble it. Prototypically it would be rivetted but I am tempted to try MIG welding it. Being enclosed, I could rivet only one seam, the lower one as that would be the more visible one. On the other hand my welding is very rough, to say the least.

I might use small (M3) dome-headed cap-screws and nuts, at least on the top plate. When painted over, these resemble rivets reasonably well; and that set would be barely noticeable anyway. The ash-pan is nearly a third of the way back from the front of the vehicle, and that is two feet wide.

Refer back to my partial rendering of the wagon: The toffee-coloured bit represents the boiler's cylindrical firebox, with a glimpse of its foundation area just visible. The horizontal barrel is hidden between the bunkers. The small disc on it, is the top of what the manufacturers called the "stoking-shoot" .

27 December 2022 at 06:45 #626252derek hall 1

Participant@derekhall1Was planning on spending some time in the workshop on the Quorn grinder, but yesterday noticed a water leak through the flat roof of my workshop.

So it looks like I will be outside the workshop replacing some of the perished roofing felt.

In the summer I will have to strip it all off and inspect the condition of the top decking before I refelt completely.

The roof didnt do too bad, I laid the felt back in 2008

I would like to consider some alternative methods though, including modifying the flat roof to increase the pitch, but that is not a job to do in the middle of winter !

Happy Christmas all and all the best for 2023

Derek

28 December 2022 at 23:16 #626547Nigel Graham 2

Participant@nigelgraham2Derek-

What you might consider using is wriggly-bituminous sheeting, made in black or dark-green; laid on timbers over the existing boards to give a shallow slope. You'd need close the ends of the wriggles of course, using the moulding supplied for this, and fit barge-boards to come below the existing woodwork.

++++

Wot I Dun:

A soggy trip to town, momentary hope soon dashed, and a little more work on the steam-lorry.

Despite the bad weather the town centre was actually quite busy. I noticed no copies of our magazines in W.H. Smiths, but I don't know if by publication date or by the shop no longer stocking them. (I subscribe to ME.)

+++++

Moment of Hope:

I discovered this evening that SolidEdge has a directly orthographic ( "2D" ) mode – perhaps possible for me.

SO I tried it.

Only, the cited exercise file and its path did not work, perhaps did not even exist. Then as SE's final insult to injury, the normal "Exit SolidEdge" tool did not work either.

No other choice: I closed the programme by Task Manager, then removed it and deleted my few exercises.

A relief, but Oh! – what a waste of time, effort, stress and electricity, just for complete failure.

+++++

To What Matters:

A little more metalwork for the steam-wagon, and trying to assess how to thread the main water-pipe forwards from the tank floor, past the brake cross-beam and rear axle, to the vicinity of the engine and boiler.

That's not easy.

The differences in level and the spaces between them are not very large but together they take a fair depth, and I don't want to reduce the ground-clearance more than necessary, especially with fairly fragile parts.

Also I don't know yet what space where, will be occupied by the engine-case and either flywheel or transmission – depending which side of the chassis will be the better for the pipe to follow.

I am fitting a length of ordinary 15mm pipe to finish near the engine and boiler, by branching into smaller-diameter pipes to the feed devices.

My aim, such as it is, is to complete the steam-making parts first to serviceable state before concentrating on the steam-using parts. I could temporarily link the plumbing by hose until I have made enough of the machinery to suspend that in the chassis.

28 December 2022 at 23:53 #626549 Grindstone CowboyParticipant@grindstonecowboy

Grindstone CowboyParticipant@grindstonecowboyDerek – I can heartily recommend the EPDM (rubber) roofing membrane, I've done a few flat roofs with it now, and it's far better than felt in my opinion. More expensive, though, but re-roofing isn't something you want to redo very often.

Rob

29 December 2022 at 00:07 #626550 BazyleParticipant@bazyle

BazyleParticipant@bazyleI had a rubber roof when I moved in and it stank of plastic in hot weather, then gradually hardened and squirrel/cat claw scratches caused tears, the joints pulled apart and leaked. Lasted about 10 years. Replaced with triple layer felt from Wickes, NOT torch on, twenty years ago, Just don't bother with 'shed' quality felt.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › The Tea Room › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Adjustable spanner thread direction

Started by:

jimmy b

in: Workshop Tools and Tooling

jimmy b

in: Workshop Tools and Tooling

- 5

- 5

-

11 July 2025 at 20:32

Nicholas Farr

Nicholas Farr

-

Another Day … Another ScumBag

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 10

- 15

-

11 July 2025 at 20:09

V8Eng

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 16

- 30

-

11 July 2025 at 19:12

Nealeb

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 102

-

11 July 2025 at 18:48

Diogenes

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 9

-

11 July 2025 at 17:32

renardiere7

-

buying machine tools from aliexpress experiences?

Started by:

Jake Middleton-Metcalfe in: Manual machine tools

- 12

- 15

-

11 July 2025 at 17:17

larry phelan 1

-

Old plastic handled screwdrivers

Started by:

Dave Halford

in: Workshop Tools and Tooling

Dave Halford

in: Workshop Tools and Tooling

- 12

- 14

-

11 July 2025 at 17:14

Robert Atkinson 2

Robert Atkinson 2

-

Bridgeport ways and wear

Started by:

inline in: Manual machine tools

- 7

- 18

-

11 July 2025 at 09:16

Ian Owen NZ

-

Maisie lubricator

Started by:

ferroequinologist in: Locomotives

- 9

- 14

-

11 July 2025 at 09:09

Clive Foster

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 13

- 26

-

11 July 2025 at 07:11

Nicholas Farr

Nicholas Farr

-

Transwave converter – plugged in motor, tripped RCD

Started by:

ell81 in: Beginners questions

- 8

- 12

-

10 July 2025 at 22:56

Master of none

-

Eight Trains

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 1

- 1

-

10 July 2025 at 14:14

Vic

Vic

-

motor and switch wiring Myford ML7

Started by:

1957jmh in: Workshop Tools and Tooling

- 3

- 5

-

10 July 2025 at 12:02

noel shelley

-

Help Wire 3 Phase 2 Speed Motor

Started by:

Allan Day in: Electronics in the Workshop

- 13

- 23

-

10 July 2025 at 11:57

Andrew Skinner

-

Square end on round stock – Milling?

1

2

Started by:

Roger TheShrubber in: Workshop Tools and Tooling

- 16

- 29

-

10 July 2025 at 10:49

Julie Ann

Julie Ann

-

Easiest/cheapest source of R8 socket

Started by:

Beardy Mike in: Workshop Tools and Tooling

- 8

- 10

-

10 July 2025 at 10:16

Pete

-

New (but well aged) member

Started by:

mikemunson in: Introduce Yourself – New members start here!

- 6

- 6

-

10 July 2025 at 09:23

Dell

Dell

-

Bosch PBD 40 bearing upgrade

Started by:

th1980 in: Manual machine tools

- 5

- 11

-

9 July 2025 at 22:00

th1980

-

Bearing boxes for ball race

Started by:

Paul McDonough in: Beginners questions

- 11

- 20

-

9 July 2025 at 20:38

old mart

-

Twin Engineering’s heavy mill/drill quill removal

1

2

Started by:

Martin of Wick in: Manual machine tools

- 11

- 34

-

9 July 2025 at 19:42

old mart

-

File backup to external hard drive, incremental etc?

Started by:

Peter Bell in: The Tea Room

- 11

- 17

-

9 July 2025 at 13:50

Graham Stoppani

Graham Stoppani

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 186

-

9 July 2025 at 12:28

Paul Kemp

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 34

-

8 July 2025 at 23:53

Bazyle

Bazyle

-

Angle grinder woes

Started by:

Speedy Builder5 in: Workshop Tools and Tooling

- 5

- 8

-

8 July 2025 at 18:26

DC31k

-

in line oil check valve

Started by:

Garry Coles

in: General Questions

Garry Coles

in: General Questions

- 5

- 5

-

8 July 2025 at 18:05

salatipa

-

Adjustable spanner thread direction

-