Yesterday I went to an all day seminar at the local gliding club on pilot/owner maintenance. In other words what EASA allows the owner of a glider to do, as opposed to an inspector. As far as EASA is concerned the owner is responsible for organising, and possibly doing, all maintenance, even if they've never held a spanner before! Of course I'm an owner, and pilot, but since I'm also a BGA inspector I can sign off work anyway. However, as an inspector I may be called to sign off work by non-inspectors, or to issue an ARC where the owner has done, and signed off, a lot of the work. So I thought I'd better find out what the owner is allowed to do, and how to judge competence. Turns out to be rather a lot, the main exception being that they're not allowed to fiddle with primary controls or other life critical systems. It was also a chance to meet the BGA CTO; nice guy and very approachable, unlike the last one.

Today was spent largely in the garden hacking back the blackberries. However, this afternoon I got my neighbour to help me lift the arbor press on to the bench. Took about 5 minutes and no trips to A&E needed; a win-win situation. I knocked out a few large washers and bolted the press to the bench with some stainless steel M12 bolts and nylocs from the spares bin. The ram and lever were cleaned, greased and replaced:

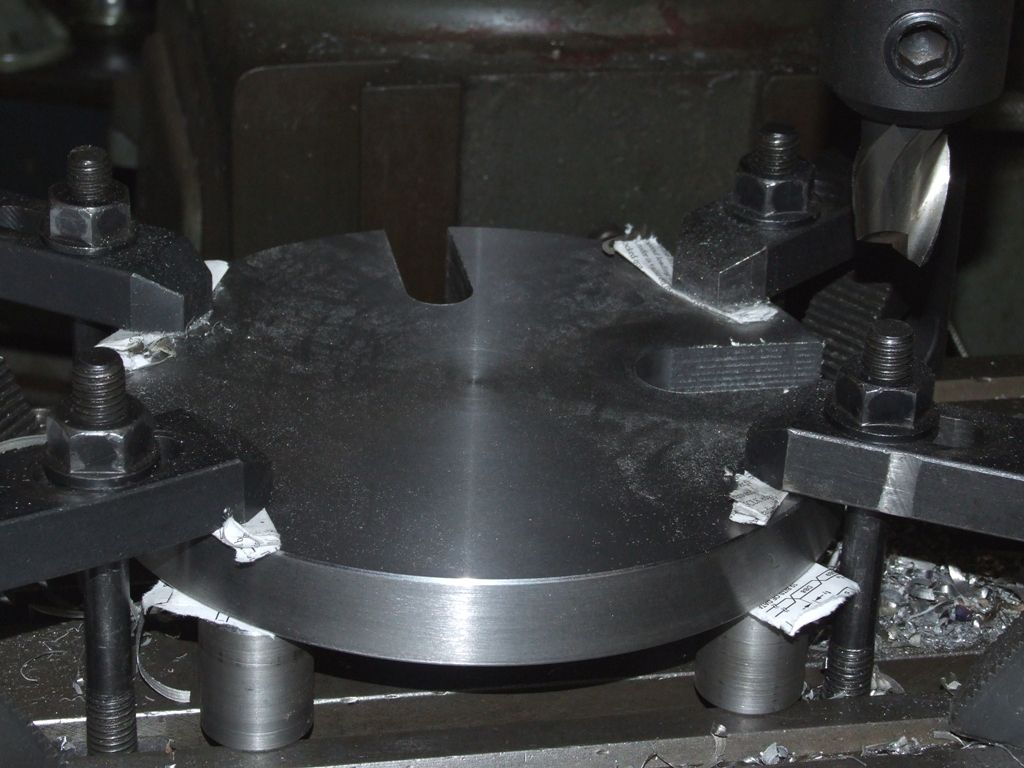

Later this evening I started machining the slotted plate that will go on the arbor press. The 3/4" and 1" slots were drilled and then finished with slot drills:

For the 1-1/2" and 2" slots I'll chain drill out the waste and machine a circle with the boring head. Then I'll chain drill the waste for the slot and finish with an endmill.

Andrew

BGA = British Gliding Association

CTO = Chief Technical Officer

EASA = European Aviation Safety Agency

ARC = Airworthiness Review Certificate – a paperwork exercise to check that the aircraft is 'compliant'

JasonB.

JasonB.