John,

I think I'm trying to make a general point:

Our suppliers generally do a good job of replacing faulty items found on receipt, as shown by the numerous posts on here.

Not sure how any guarantee might work, as in your case. I once had a washing machine (premium brand) that died in month 13 – supplier/manufacturer – not interested at all.

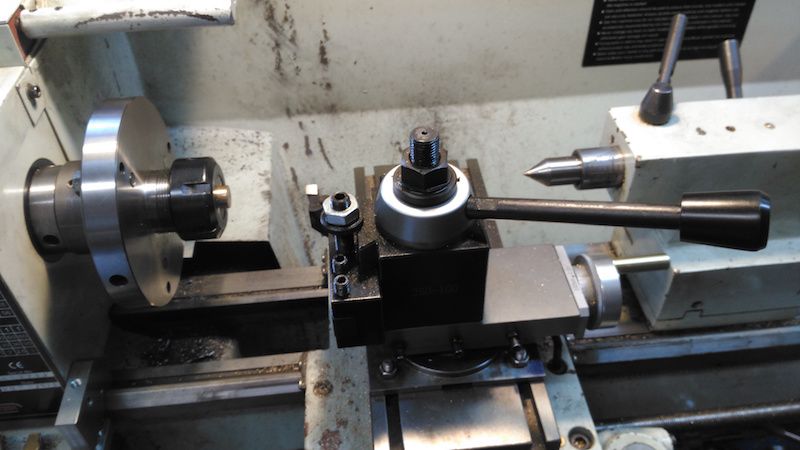

Unfortunately this is not an isolated case for me, within the last 2 weeks; I've had, from different suppliers, a damaged centre in a RT tail-stock (poor packing), a faulty Indexing Kit for the ubiquitous 4" Rotary table and now 8 "Dixon" type QCTH's which don't seem to relate to any specification at all, even within the same supplier, see other post "QCTH a Couple of Questions".

The tail-stock was replaced without question and I decided to investigate the faulty Indexing kit:

Once assembled on the RT, the plunger would not reach the plate, the plunger is held in the arm with a grub-screw but the plunger was stuck-fast part way into its location hole and it was clear to see that the end of the plunger had been beaten with a hammer, most likely to "help" the plunger into some sort of position.

Thinking that I'm likely to get the same if replaced; I set to and reduced the diameter of the plunger housing so that it was a slip-fit in the hole. Success and no need to wait in again for a replacement.

Neil, you suggest that prices would rise if better quality control was implemented. Manufacturing inspection (in-process and final) still costs much the same.

If manufacturing staff had the authority / training to reject faulty parts at the earliest opportunity, savings could be made at next to no cost.

Fact: It costs more to produce scrap than fit-for-purpose items:-

1) Wasted raw material

2) Wasted machine time

3) Wasted energy

4) Wasted packaging and time

5) Wasted storage and transport

6) Wasted picking and packing for sale

7) Wasted delivery costs

8) Lost of confidence by customer receiving faulty goods (very hard to recover, if at all, as in John's case with the chuck)

9) Potential loss of Life-Time-Value of Customer (total in John's case)

10) Cost of Customer Service time sorting out the problem

11) Cost of return to supplier

12) Cost of rejection inspection

13) Cost of replacement item

14) Cost of hiring a skip for waste disposal

Yes, I know I'm hi$$ing in the wind; but I'm off to the workshop now its had chance to warm up.

I've got one more QCTH to linish so that it fits my tool-post – the process might be a candidate for Bodger's Lodge!

Then I can sort the RT fixings for my new shiny chuck.

Regards

Phil

Edited By CotswoldsPhil on 14/01/2016 13:40:09

JasonB.

JasonB.