Today I convinced myself that I am almost there with the re-arrangement of the workshop. Since buying a Tormach CNC Mill last year I have had little time,due to work commitments, to get round to generating a more useable workshop space so that I can get stuck into learning how to use the mill.

I have a lot crammed into my workshop, including 5 motorcycles which are housed at one end of the garage in a space approximately 11 ft x 10 ft. I have a storage bike lift which enables me to put two bikes underneath and two on top, The remaining space is just sufficient to enable me to work on a motorcycle or to park the latest machine of choice.

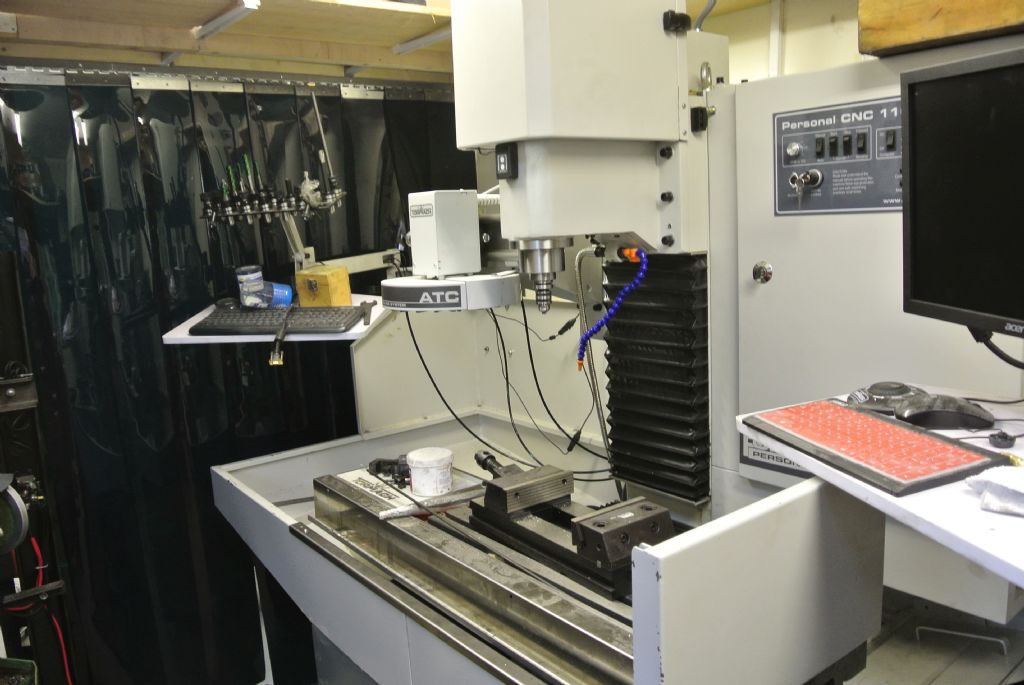

Next area is the machine shop area, this houses the Tormach PCNC mill, the Warco Manual mill, Myford MG 12 Cylindrical grinder, Bench Drill, Mini-Lathe and Cutter grinder as well as the compressor for the Auto Collet on the Tormach and an inverter for the Cylindrical Grinder. I reckon the space that all of this is housed in is somewhere in the region of 15 ft x 11 ft. At the far end of the workshop there is an area of approximately 10 ft x 11ft that houses the work benches, welding equipment and a newly acquired muffle furnace, all dirty work is carried out in this area.

I decided that I must keep the three areas separated to prevent dust and grime from the dirty end of the workshop invading the machine shop and motorcycle areas. To do this I opted for the easy solution of fitting some curtain doors. These are easy to make up and fit taking only a day to do. I have fitted the curtains with velcro patches that enable me to roll them up to make access easier when I am not doing any dirty work or if I am moving between work bench and machines a lot.

I never liked the idea of putting any machine tool onto a rolling trolley but decided that this was going to have to be done to enable me to maximise the space. I also decided that i would have to put up with using the manual mill without the chip tray extension because it took up too much room. I set too and made two trolleys, one for the Warco mill and the other for the BH 600 lathe.

The picture below shows the BH600 Lathe and the Mill. A close look will reveal the trolley under the lathe, the castors have a dynamic loading of 500 KG and a static loading of 1000KG so should be ample. The frame is made from 4" channel.

This picture is view down the workshop, three of the bikes are visible.

One of the curtain doors that separate the dirty end of the workshop from the machine shop.

By moving the mill and Manual lathe to their current positions I generated quite a bit of useable space in which to make a fitted bench and storage rack for material enabling me to put the mini lathe, tool and cutter grinder and bench drill on it.

After completing the bench and storage racks I moved all of the tools from their former positions to their new in the storage bench. I am sure I will take a good while to get used to where things are but I like the layout so far.

This picture shows the new bench/storage rack with the bench drill, cutter grinder and mini lathe in position.

Another view, the storage rack visible on the right.

View of the storage cupboard below the bench. Note the castors on the service trolley on the left and also the castors and trolley on the manual mill just visible beyond the service trolley.

View of Manual mill and lathe.

View down workshop toward (Dirty end) of workshop showing curtain doors rolled up.

View of the Myford Cylindrical grinder and rotary inverter. (90 degrees out)

The newly acquired Muffle furnace (with controller that has an instruction manual that is impossible to follow)

The Tormach Mill that started all of the re-arrangement is in it's final position.

All I have to do now is make some doors for the cupboards and some covers for the storage rack and I will be in a good position to begin to teach myself how to use the CNC mill.

JasonB.

JasonB.