Posted by Muzzer on 16/04/2015 21:22:29:

Oompa Loompa – are you reusing those cases? I know nothing of these things but just wondering how you fit the detonators etc safely. I assume you buy them ready to press into the case, then afterwards fill the case and fit the tip?

Is there any significant danger in running around carrying bandoliers of rounds and/or "pouring" loose rounds, given the vague possibility of setting off a detonator?

Murray

Ohh Yes! Always reuse the brass. Dear stuff and this is quality stuff. If you are a little conservative you can relouad the brass well into 14-16-18 times. By reloading I reduce dramatically the cost of my shooting, thing is, reloading is a whole subject all on it's own but terrific for tinkerers such as us. The length of the brass is important, the projectile seating depth is critical and there needs to be a careful note kept as to how much and what type of powder. There are a number of proprietory tools to enable you to seat the primers safely and then you add the powder and finally – using a press you seat the bullet. During the preparation stage you resize the full length of the case or just the shoulder – all depends on a number of factors.

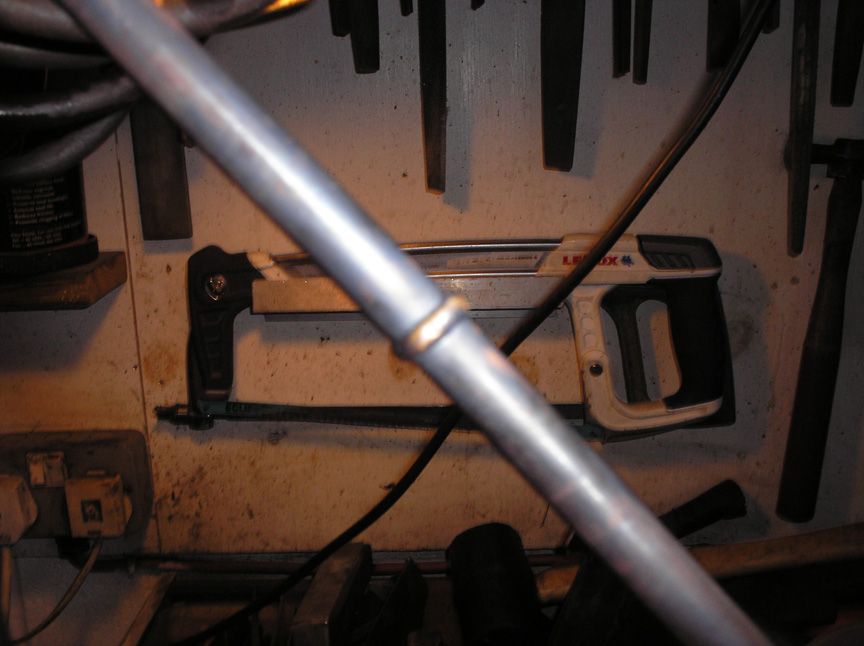

I use a decapping die first off before anything to remove the primers then I clean the cases. I am building a tumbler at the mo which will use very fine stainless pins to clean the cases. My friend has one and it is excellent.

Then I lightly lubricate the cases and resize them prior to inserting the primers.

Having one pointy tipped bulet directly behind another could turn nasty, I keep all completed ammunition in special plastic cases that hold the rounds securely. In those firearms that have a tubular magazine under the barrel, round nose ammunition is used and in all the years I have never heard of a mishap. Putting a slack handful of ammunition in your pocket isn't smart either, for a start it will pierce the lining nd you will be learning to sew real fast. Shotgun shells are different again – you just stick them in a coat pocket. The only caveat is NEVER BUT NEVER have a 12gauge and a 20 gauge out at the same time. A twenty gauge shell slips down the barrel of a 12 gauge and when the gun doesn't go off and you open it you think it is empty, stick some 12 gauge shells in there and BOOM! Big bang!

graham.

JasonB.

JasonB.