Tested my 9 year old C3 Minilathe (after reading of Brian John's tribulations and Hopper's remedies).

After minimising the X-slide errors, the dti revealed that the carriage gibs (brass) had a little play and the X-slide gibs were allowing the slide to lift slightly. So I got stuck into it (thunderstorms outside).

Carriage gibs adjusted in-situ by using a cut down Allen key ¤

Inspected X-slide gib wear pattern and lapped away few small ridges, tested with bearing blue ¤

Added 3 small ball bearings under X-slide cup-point gib adjusting screws – now it's smooth ¤

Lapped and scraped away a few small ridges under tailstock V groove.

Put a 12" length of 3/4" steel bar in the 3-jaw and leaned on it while watching the dti, 0.01mm, not bad! ¤

Put 3MT centre in headstock spindle, 2MT dead centre in tailstock and tried a razor blade test ¤

After 9 years of regular use, a bit of fettling and some TLC the little C3 just gets better.

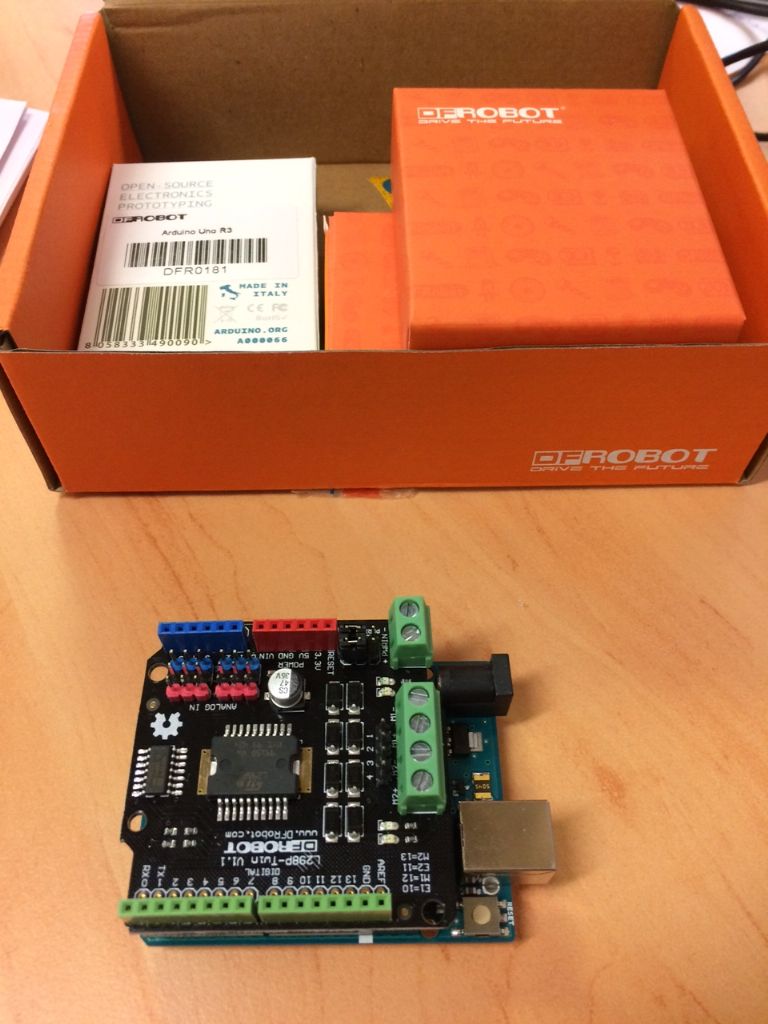

Just to test the new set-up I treated the tailstock to a new toy ¤

* Danny M *

Edited By Danny M2Z on 11/11/2015 09:39:39

JasonB.

JasonB.