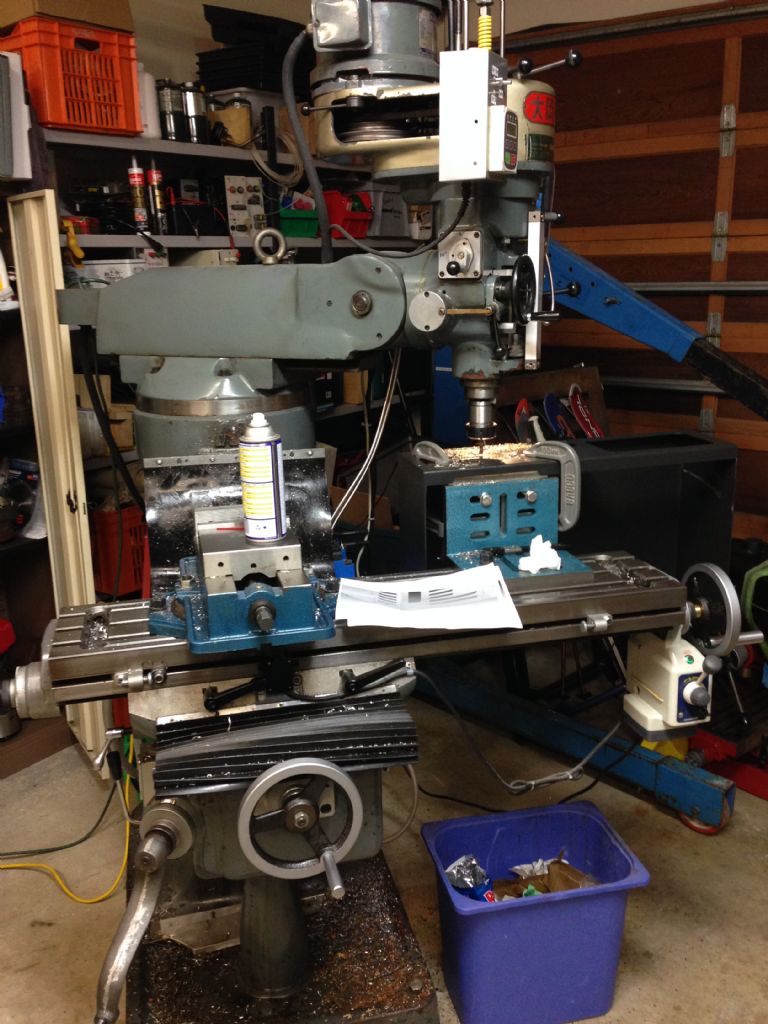

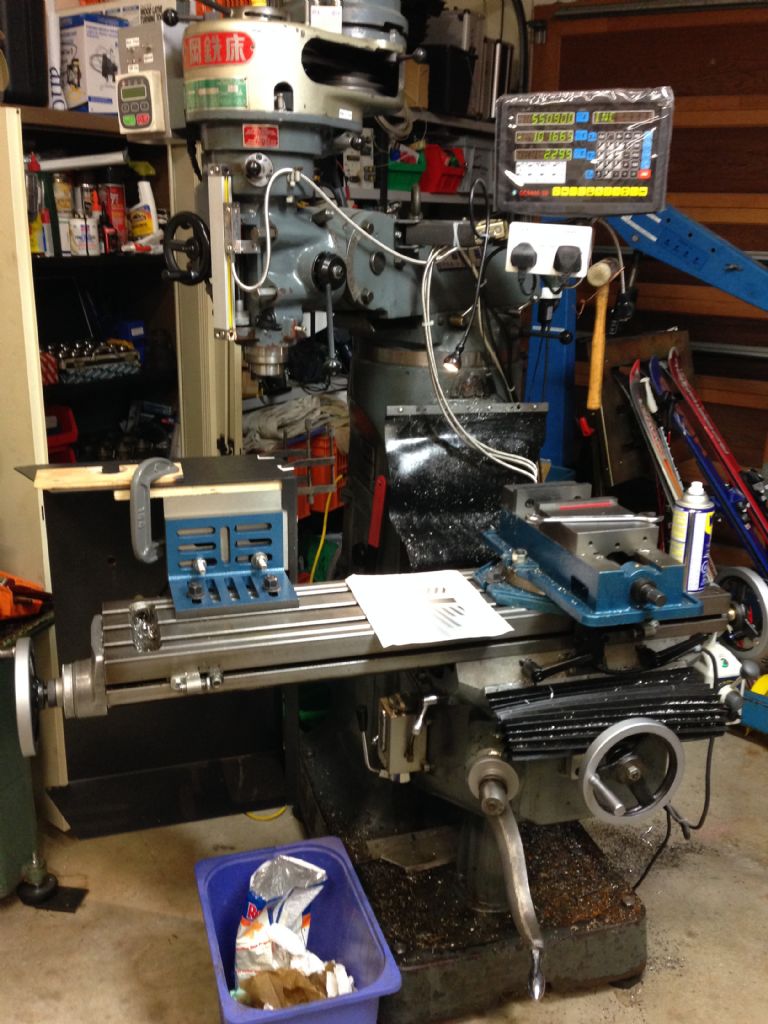

Bad day today, well late afternoon.

Some kind soul gave me an old oil cooled welder with no guts in it for a coolant tank, found a big pump and was just going to fasten it to the side [ side mounted pump ] and decided to have a quick measure up where it should go.

Damkit, too tall, can't get the shelf in I need. Where's me angle grinder [ I love that angle grinder  ]

]

Chopped the tank in half, ground the welds off the top support on the scrap bit and weld it back on to the new bit.

Then did one of Baldrick's Cunning Stunts. Drilled and tapped 6 holes in the side and two 16mm holes.

Cuts some profiles out on the laser, some gaskets, two whit perspex shapes, one clear shape and a steel cover piece.

It assembles as gasket, bit with two holes, gasket, bit with slot, gasket, clear cover than steel cover.

Result ?

Now got a sight gauge. Also welded a big 2" has thread and cap in so I can try to get some coolant in.

Also before someone mentions white suds not showing up on a white background [ bit like the Italian flag, white cross on white background ] this machine is going to be running neat cutting oil so it will show.

Bit of a flash round with a rattle can and jobs a good un.

[EDIT]

Damkit just read Coal burners post above this one, have to get me finger out.

Obviously coal burners are quicker than wood burners

Edited By John Stevenson on 27/02/2014 22:08:53

John Haine.