Here are some pictures of the mayhem created by trying to find space for all of my machinery after importing a Tormach PCNC 1100 Mill. i finished putting up the curtain door in the "Dirty End" of the workshop tonight.

It's an Easy job, just a case of cutting the strips off a roll, pop riveting the hanger plate and backing plate onto one end then hanging on the rail. This should keep the dirt from cutting grinding and welding in the far end of the shop. You can also see some of the shelving I have put up, The shelves are due to be completely reorganised and all of the kit for welding operations will be stored in the appropriate end of the shop.

As you can see I am trying to cram a quart into a pint pot. For those interested the bikes are, left Velocette Thruxtonised Venom, BSA RGS A-10 Lookalike under bike storage lift and on top of the lift is my 1927 Humber side valve. There also lurks a 1929 Humber 350 OHV and a BSA DBD 34 Gold Star.

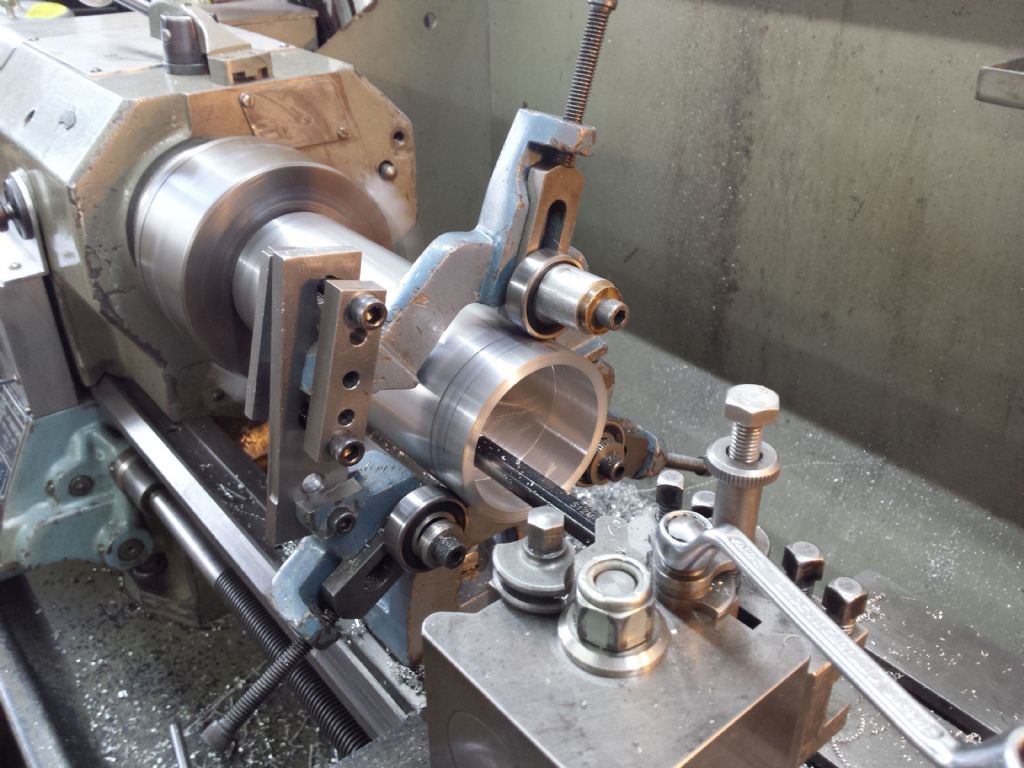

Here's another view down the machine shop area showing the Warco Manual mill, Warco BH 600 Lathe and the Myford MG-12 Cylindrical grinder. The latter is a three phase machine and I use a rotary inverter to run it, this is visible above the grinder. The bench drill has been relegated to the dirty end of the workshop and is visible in the distance.

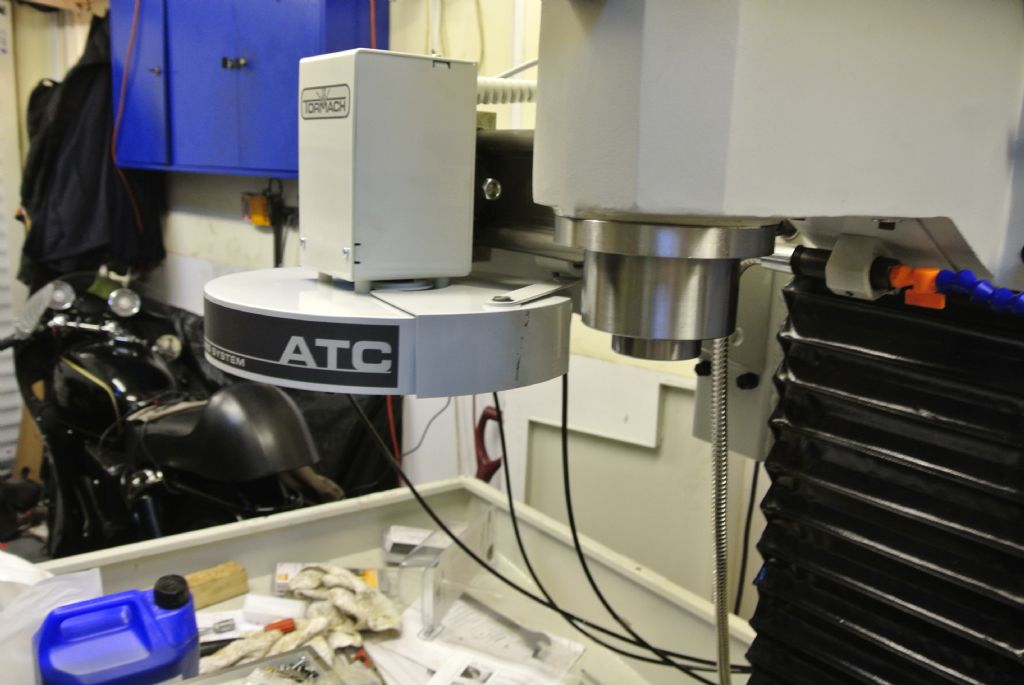

The Tormach with ATC, as you can see, apart from running a test programme I haven't used it in anger yet.

Another view showing the Tormach mill and the Warco manual mill.

The space created for the Mini Lathe,Tool & Cutter grinder and the bench drill.

The completed Curtain Door. I was amazed at how much the heat is held in by the curtain, while putting it up I had a small fan heater running just to keep the chill off me but very shortly after I got all of the strips hung I had to turn it off.

I hate to think how hot it will get in there when I am doing any big brazing jobs.

John Haine.