Certainly no Sandown finish on my gear,it has to work for it's keep

Anyway day didn't go as planned.

Brecky took longer than it should because the lady in the pub felt sorry for me and bunged a couple more hash browns on me plate.

Then whilst i was having it, got a text asking can i do a pump this morning. because of all the flooding down south the motor repairers in those area's are flooded out, either with work or just flooded out. result is they are sending work anywhere they can get a fast turn round.

Anyway did the pump, simple job, sleeve one end housing and build the rotor up and re-machine down, then started on the lathe which according to the first pic was 4:06

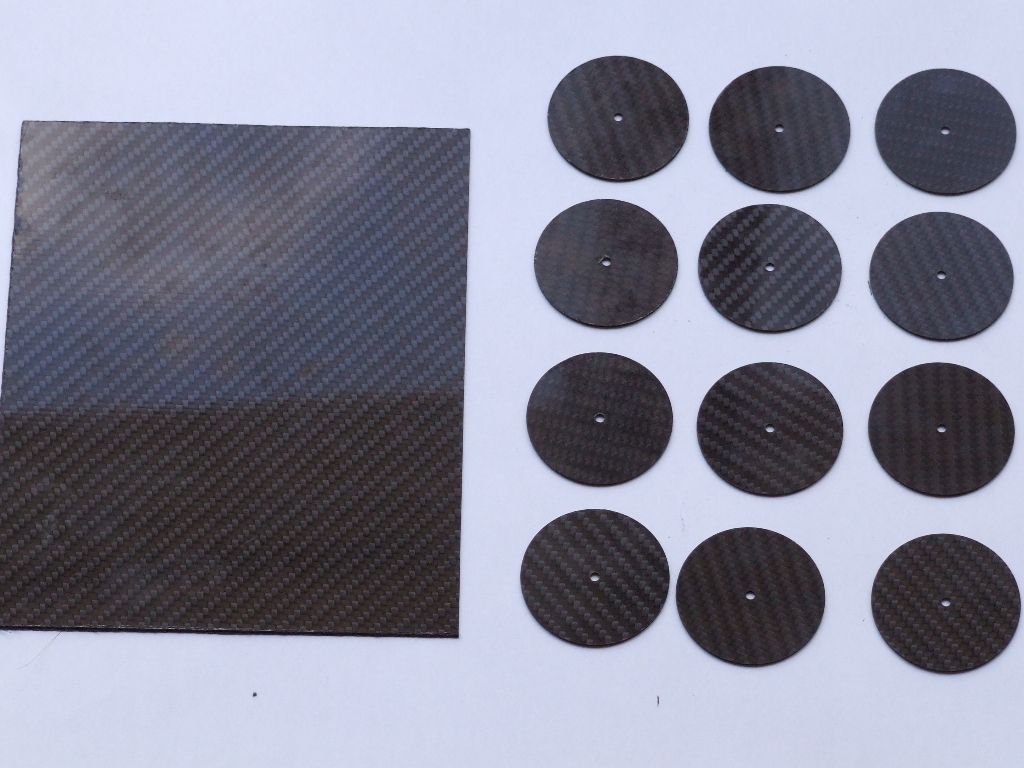

This is the standard gear setup on my new lathe.

this one ratio will do all the standard metric threads which is what it's been bought for. Imperials need different gears and invoke the 120 / 127 gears on the idler. Problem i have is with modern tooling speeds have risen from a few years ago and running at 1200 revs is now more the norm than t ever was. result is in feed mode these gears kick up a bit of a clatter.

So by 8:00 tonight this is state of play with the drive.

Gear train has been replaced with tooth belt drive to the same ratio although not the same number of teeth. Idler gear now lives on the lower guard stud and all the special gears for imperial, MOD, DP worms etc are all mounted on a bracket under the guard so no hunting for odd gears in a box somewhere. This should save me earache and time spent hunting.

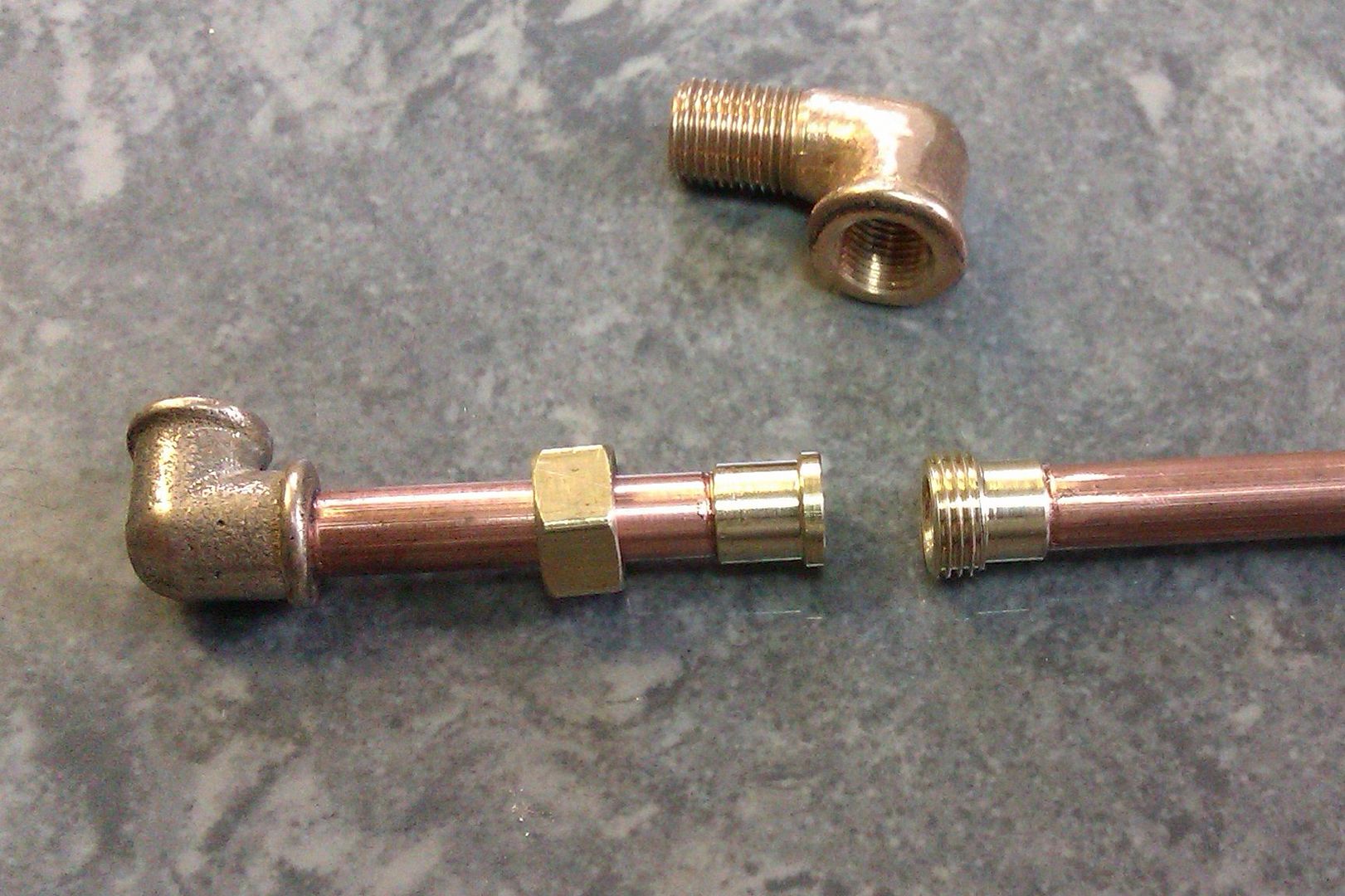

Next mod is to the tailstock, one thing about furriners, they can't design a tailstock if their lives depended on it.

tailstock with blank chuck arbor fitted and wound back to the stop, one more turn and it will eject.

Problem is there is over an inch of barrel sticking out, My TOS is the same, 20mm of lost travel.

If you cut the thread down you loose that same amount of travel at the other end and most of these lathes are short on travel to start with.

Got it stripped and worked out in my head how to fix this, started turning some new bits up and will carry on tomorrow but again late start as I have to go look at a job.

Hoping to get it to go to zero, still eject and have more travel than it has at present, can't post any sketches are drawings as there isn't any, typical weld where it touches job.

Watch this space.

John Haine.