Hi There

I wish I could afford to retire. But then I would be bored stupid. I might even have to talk to the wife!!!

I am busy setting up a decent workshop to do professional model making in the smaller scales, gauge O, possibly gauge 1 and 16mm narrow gauge. This will be a mix of one offs and batch production. I might also venture into steam engine kits from castings.

I hope this combined with writing books and articles will help me to survive for a long while.

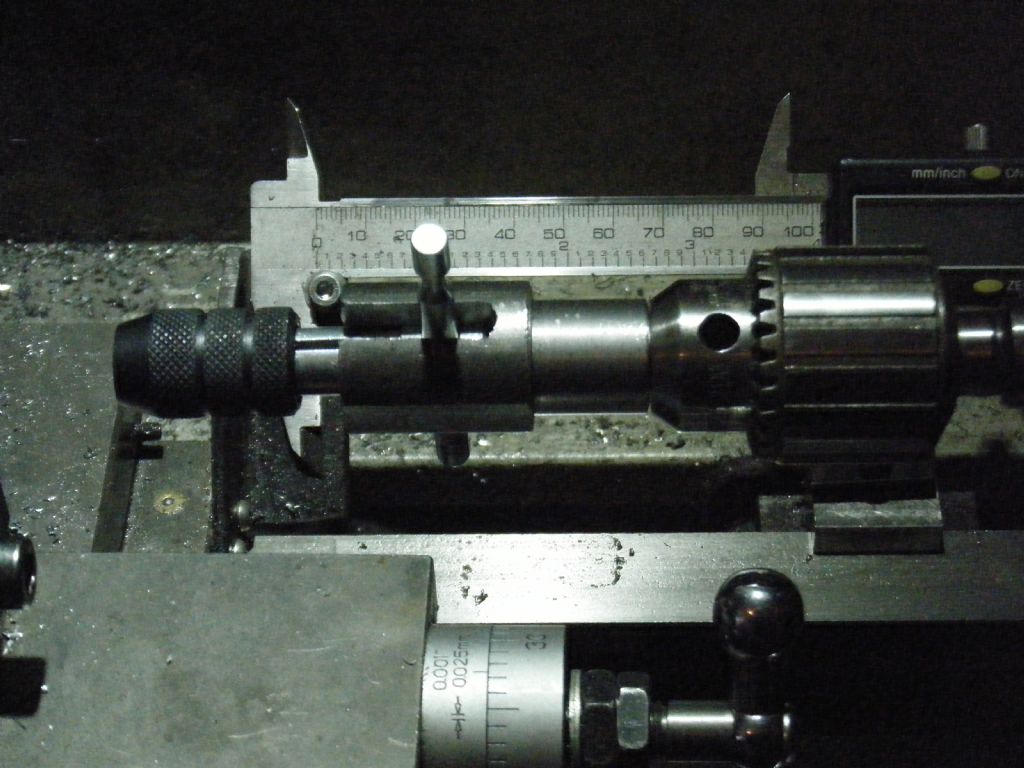

The workshop has a Warco WM180 lathe, a Myford ML10 and a Taylor Hobson Engraver so far.

I also have all I need to do resin cast rolling stock including a vacuum pump to debubble (is that the correct term) the resin.

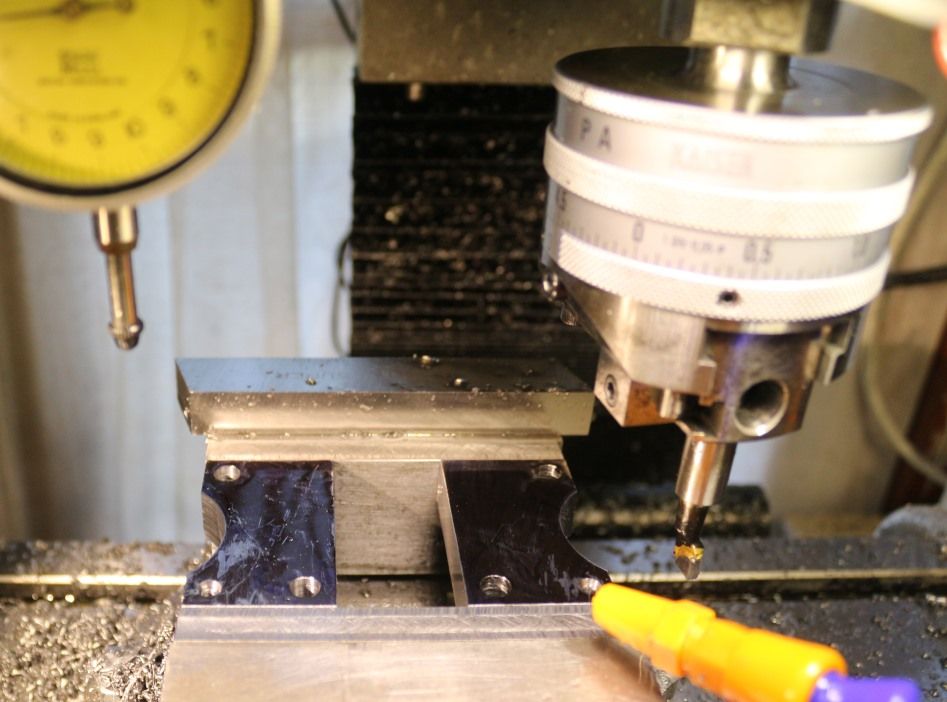

Next will be a small mill when I can afford it.

I think the secret of surviving is doing several projects at the same time to give several streams of income, as many as possible on autopilot, just fulfil the orders as they come in.

regards David

Edited By David Clark 1 on 04/02/2014 10:55:41

John Haine.