Nothing to complicated today (or yesterday). Had a go at starting to convert some end pieces from a pair of hand exercise weights into crank webs for the twin throw crankshaft for my latest build.

Before I started machining I fully expected to find cast iron but was most surprised to find they were made from what seems to me to be a very high quality nickel steel which incidentally had been plated with copper roughly .005" thick before being chromed. I call that a high standard of manufacture. Almost seems a shame to chop'em up…….almost

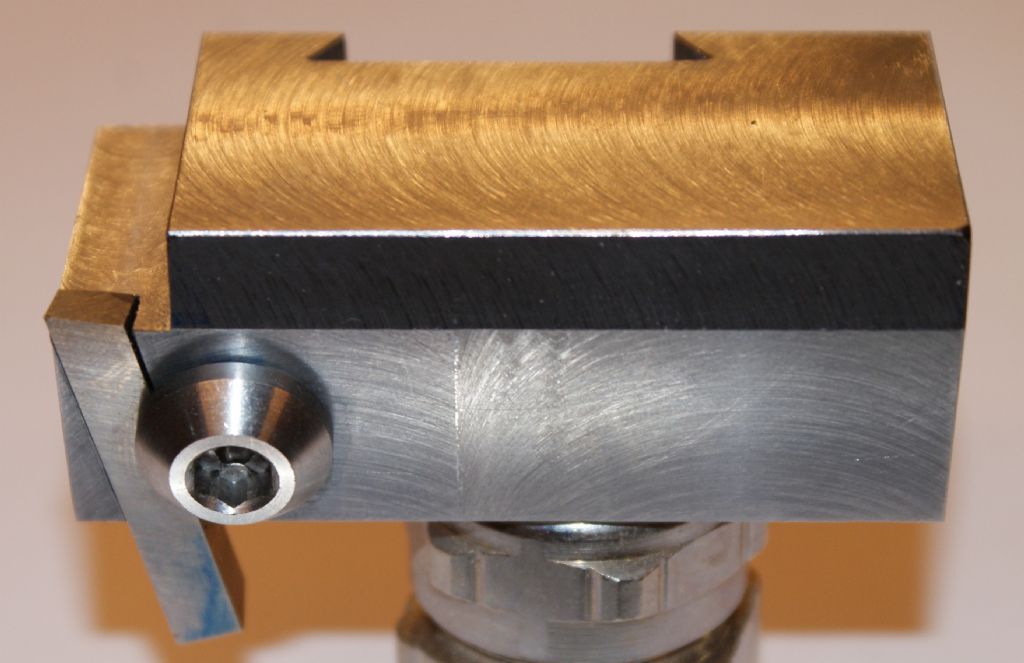

Using my homemade indexable lathe tool ( I refuse to cough up £30-40 when I can easily make one myself) I am getting lovely finishes on this material particularly on the OD which with a finishing .020" deep cut leaves it with a mirror like finish. This pleases me no end considering the set of weights only cost me two quid from my normal Sunday morning "supplier".

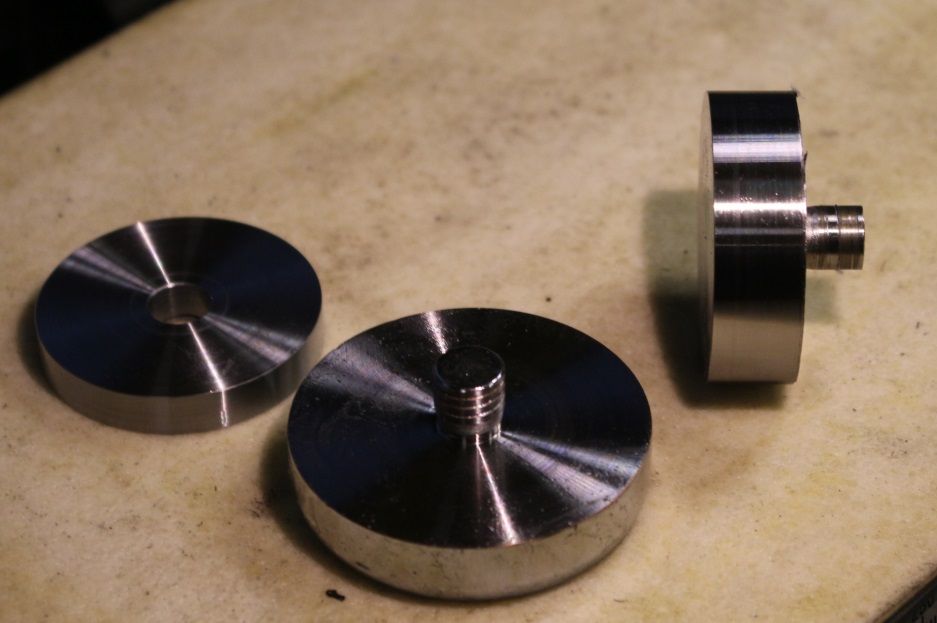

Three shown here in various stages of manufacture, the fourth is in the lathe chuck:

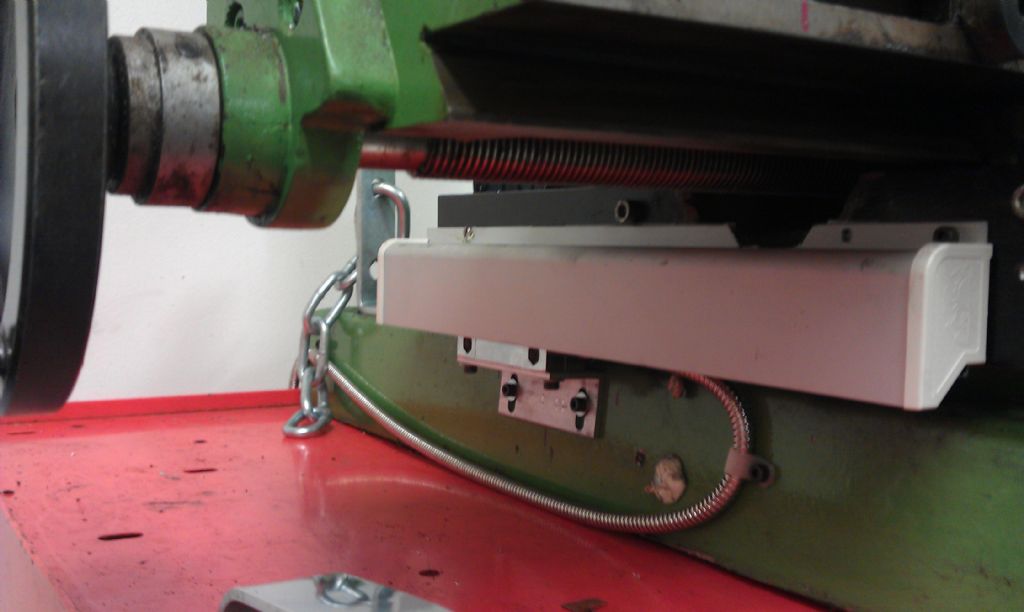

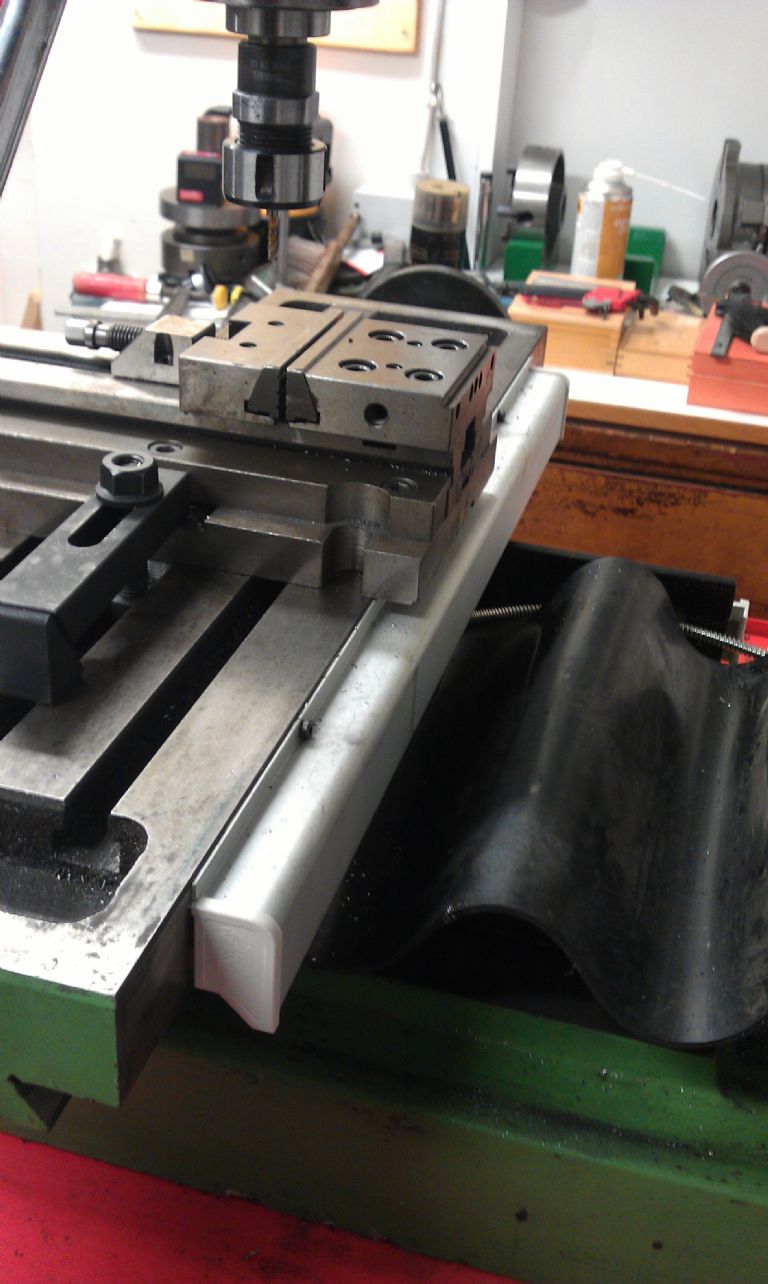

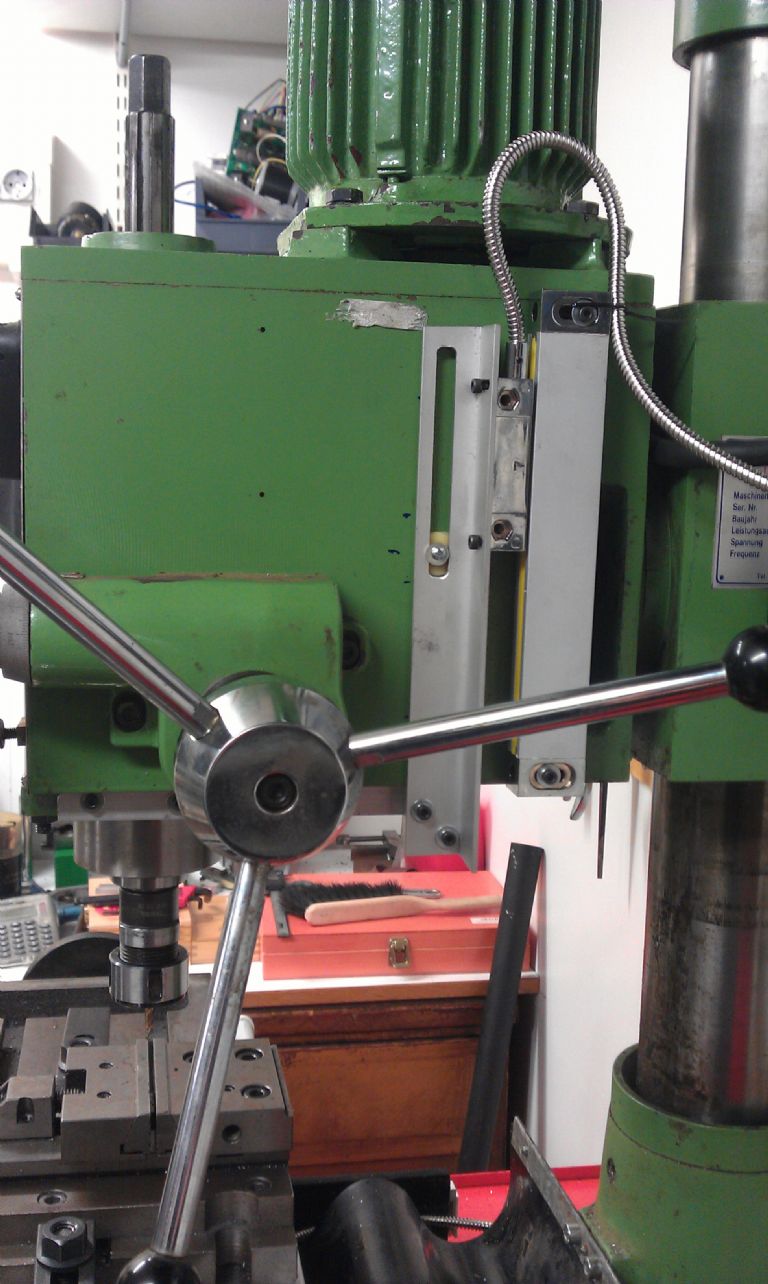

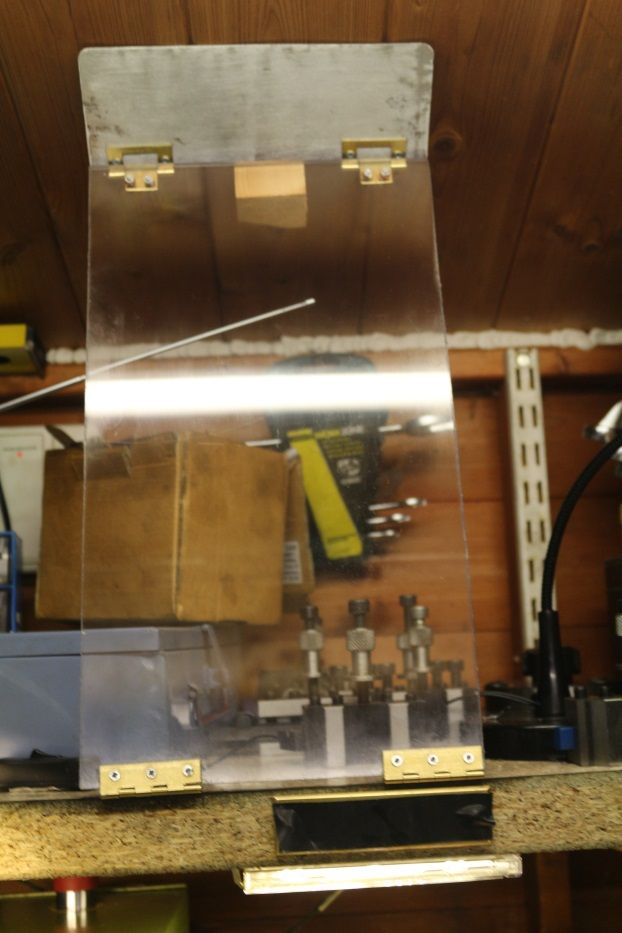

A relation works with high quality makrolon 6mm polycarbonate and he is allowed the off cuts – some "off cuts" are very large indeed! He gives me whatever I need. As you can probably see, the WARCO guard will not fit with my tool shelf over the lathe as it is, so I used a piece of this stuff to make a hinged splash guard. With it fitted I carried on machining the crank webs but found that my coolant oil was still splashing out underneath the lower edge. The solution was to hinge fit a thin sheet of ally to the bottom – problem solved…….

……..and when not needed it lives up there.

Also, as the next job is a cast iron flywheel I cut and fitted a piece of hardboard as shown to keep the dust away from the bed and lead screw. A simple life I know – maybe I should have been a monk.

May you all have a peaceful New Year and be blessed by great wealth (I could easily get into this habit)

Rik

PS Pushing seventy neither of us like noise so have booked our summer hols in Bulgaria this year – I bet we'll be able to hear a pin drop over there by then.

Edited By Rik Shaw on 01/01/2014 17:15:29

John Haine.